Processing method for improving interconnection and separation of through holes of PTFE circuit board

A processing method and technology of via holes, which are applied in the processing of insulating substrates/layers, printed circuits, and printed circuit manufacturing, etc., can solve the problem of poor interconnection of holes and walls, the effect of removing glue is minimal, and affecting the stability of circuit board signal transmission, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

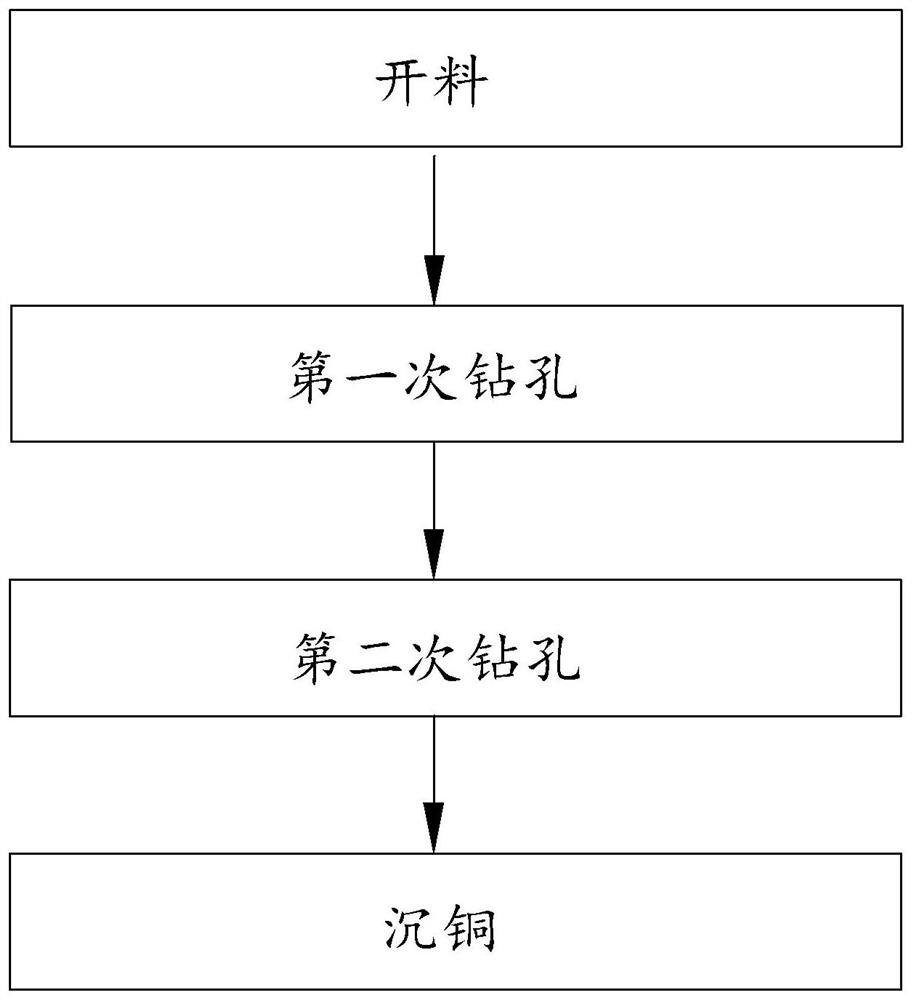

[0032] The present invention improves the processing method for the interconnection and separation of PTFE circuit board via holes, comprising the following steps:

[0033] Cutting: cutting the double-sided copper clad laminate, the middle layer of the double-sided copper clad laminate is a PTFE layer.

[0034] Drilling for the first time: select the first drill with a drill diameter of 0.25 mm, and drill the double-sided copper-clad laminate for the first time at a drilling speed of 80 kr / min to obtain via holes.

[0035] The second drilling: stop for 30 minutes, after the conduction hole is cooled, select the second drill bit with a diameter of 0.225mm, and drill the conduction hole for the second time at a drilling speed of 90kr / min to discharge the first drill Melt and fiberglass debris from holes.

[0036] Copper Immersion: First, use a plasma degumming machine to perform plasma degumming on double-sided copper-clad laminates. The temperature of plasma degumming is contr...

Embodiment 2

[0039] The present invention improves the processing method for the interconnection and separation of PTFE circuit board via holes, comprising the following steps:

[0040] Cutting: cutting the double-sided copper clad laminate, the middle layer of the double-sided copper clad laminate is a PTFE layer.

[0041] Drilling for the first time: select the first drill with a drill diameter of 0.35 mm, and drill the double-sided copper-clad laminate for the first time at a drilling speed of 100 kr / min to obtain via holes.

[0042] S4 second drilling: stop for 60 minutes, after the conduction hole is cooled, select the second drill bit with a diameter of 0.325mm, and drill the conduction hole for the second time at a drilling speed of 110kr / min to discharge the first time Melt and fiberglass debris from drilling.

[0043]Copper Immersion: First, use a plasma degumming machine to perform plasma degumming on double-sided copper-clad laminates. The temperature of the plasma degumming is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com