Device for improving installation efficiency of external liquid level meter and application method thereof

An installation efficiency, liquid level gauge technology, applied in measuring devices, lubrication indicating devices, liquid level indicators, etc. Increase the difficulty and workload of installation and maintenance, and achieve the effect of improving the transmission efficiency of vibration signals, shortening the installation time, and improving work reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below in conjunction with accompanying drawing:

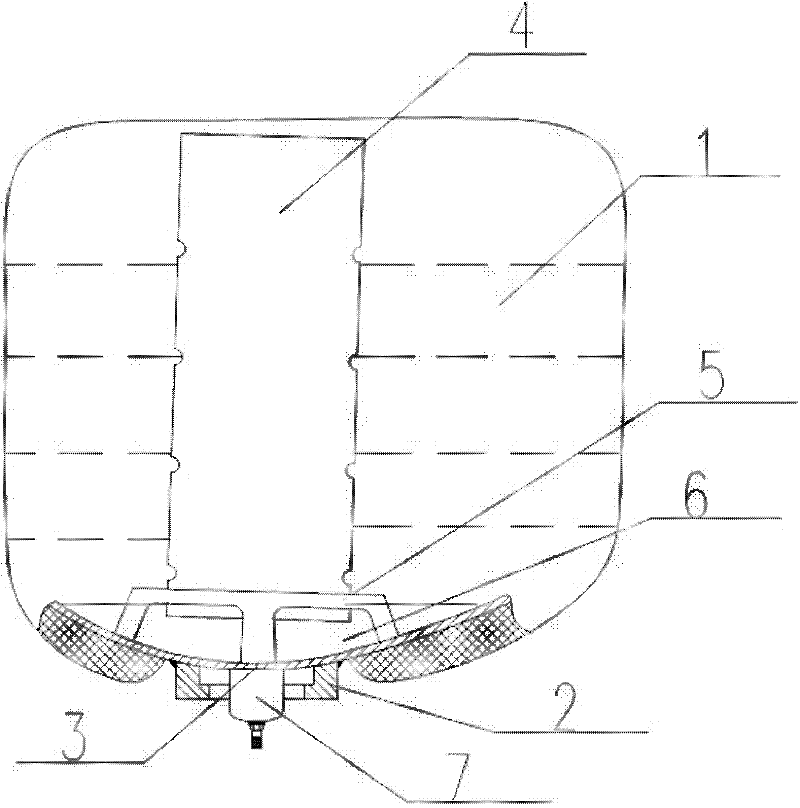

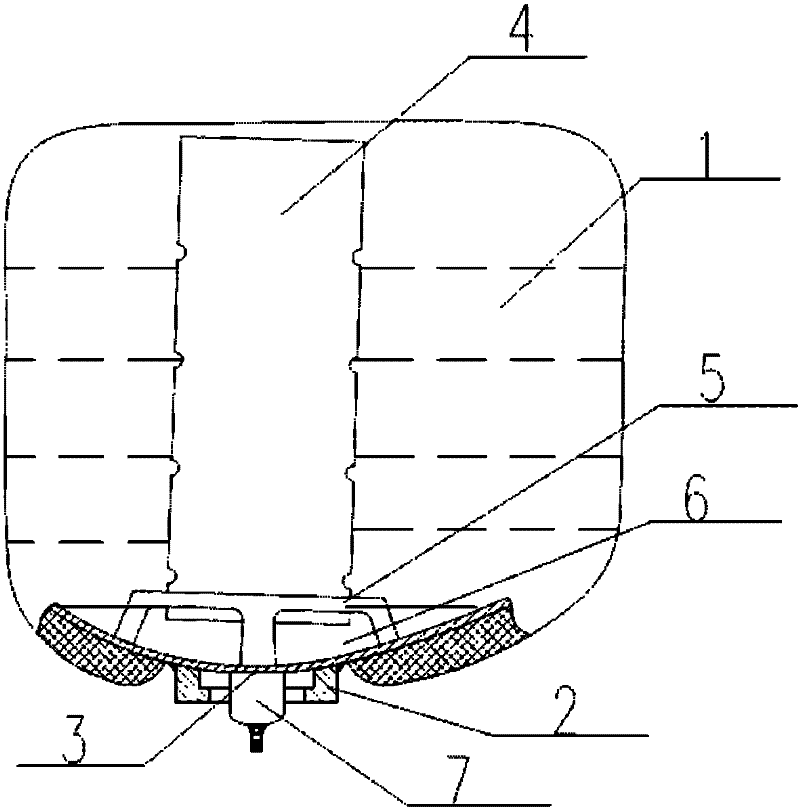

[0012] see figure 1 1. At the position where the measuring head is installed outside the bottom wall of the container, the surface of the convex container bottom wall larger than the outer diameter of the measuring head is processed into a mounting plane (3) for installing the measuring head, for example, processed into the installation plane. In this way, the entire end surface of the measuring head is in good contact with the container wall, which greatly improves the efficiency of the vibration signal passing through the coupling surface between the measuring head and the container wall. In order to ensure a high coupling coefficient between the measuring head and the bottom wall of the container, the surface flatness of the measuring head installation plane (3) should be less than 0.1 mm, for example, less than or equal to 0.05 mm. Surface roughness should be gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com