Lithium metal negative plate, preparation method thereof and secondary battery

A lithium metal negative electrode and metal lithium technology, applied in secondary batteries, negative electrodes, battery electrodes, etc., can solve problems such as easy formation of lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

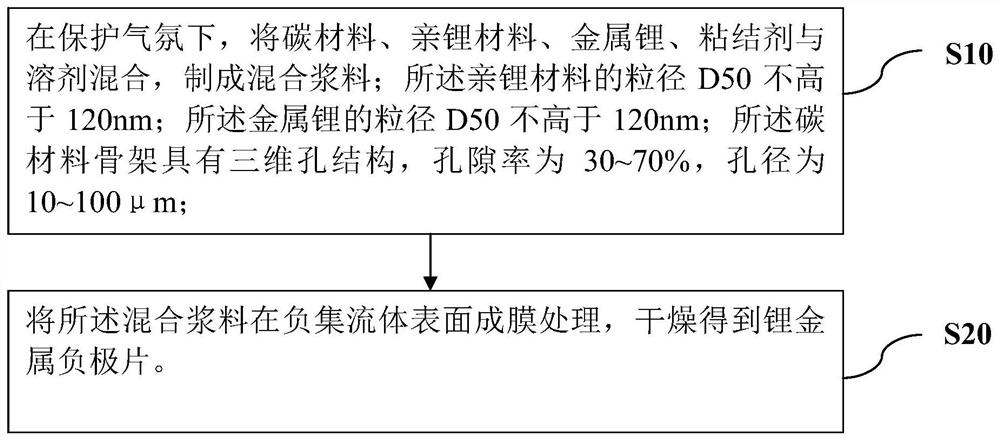

[0054] as attached figure 1 As shown, the second aspect of the embodiment of the present invention provides a method for preparing a lithium metal negative electrode sheet, comprising the following steps:

[0055] S10. In a protective atmosphere, mix carbon materials, lithium-friendly materials, metal lithium, and a binder with a solvent to make a mixed slurry; the particle size D50 of the lithium-friendly material is not higher than 120nm; the particle size D50 of the lithium metal is not higher than Higher than 120nm; the carbon material skeleton has a three-dimensional pore structure, the porosity is 30-70%, and the pore diameter is 10-100μm;

[0056] S20. Forming the mixed slurry on the surface of the negative current collector to form a film, and drying to obtain a lithium metal negative electrode sheet.

[0057] The preparation method of the lithium metal negative electrode sheet provided by the second aspect of the embodiment of the present invention, in order to avoid...

Embodiment 1

[0074] A kind of lithium metal negative plate , its preparation includes the steps of:

[0075] ①In a glove box with a water content of less than 1ppm and an oxygen content of less than 2ppm, Si particles with a particle size D50 of 50nm are used as the lithium-friendly material. The weight ratio of carbon black:lithophilic material:metal lithium is 60:30:10, which is called Take each raw material component;

[0076] ②Dissolve polyvinylidene fluoride PVDF in tetrahydrofuran THF to make a glue with a solid content of 7%; add carbon black, lithium-friendly materials and metallic lithium to the glue until the solid content is 50%; After mixing evenly, the slurry was coated on a copper foil with a coating thickness of 50 μm, and dried in a glove box at a temperature of 85° C. to obtain a lithium metal negative electrode sheet.

[0077] A lithium ion battery , the lithium metal negative electrode sheet prepared in Example 1, the lithium positive electrode sheet, the 12+4 ceram...

Embodiment 2

[0079] A kind of lithium metal negative plate , which differs from Example 1 in that: Si particles with a particle diameter D50 of 80 nm are used as the lithium-philic material.

[0080] A lithium ion battery , which differs from Example 1 in that: the lithium metal negative electrode sheet prepared in Example 2 is used to assemble a Li-Li symmetric battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com