Method for testing dynamic strain in protolith

A technology of dynamic strain and testing method, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of lack of basic research results, unclear induction mechanism, neglect of three-dimensional high ground stress state, etc., to ensure authenticity and reliability The effect of reducing the error of strain measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

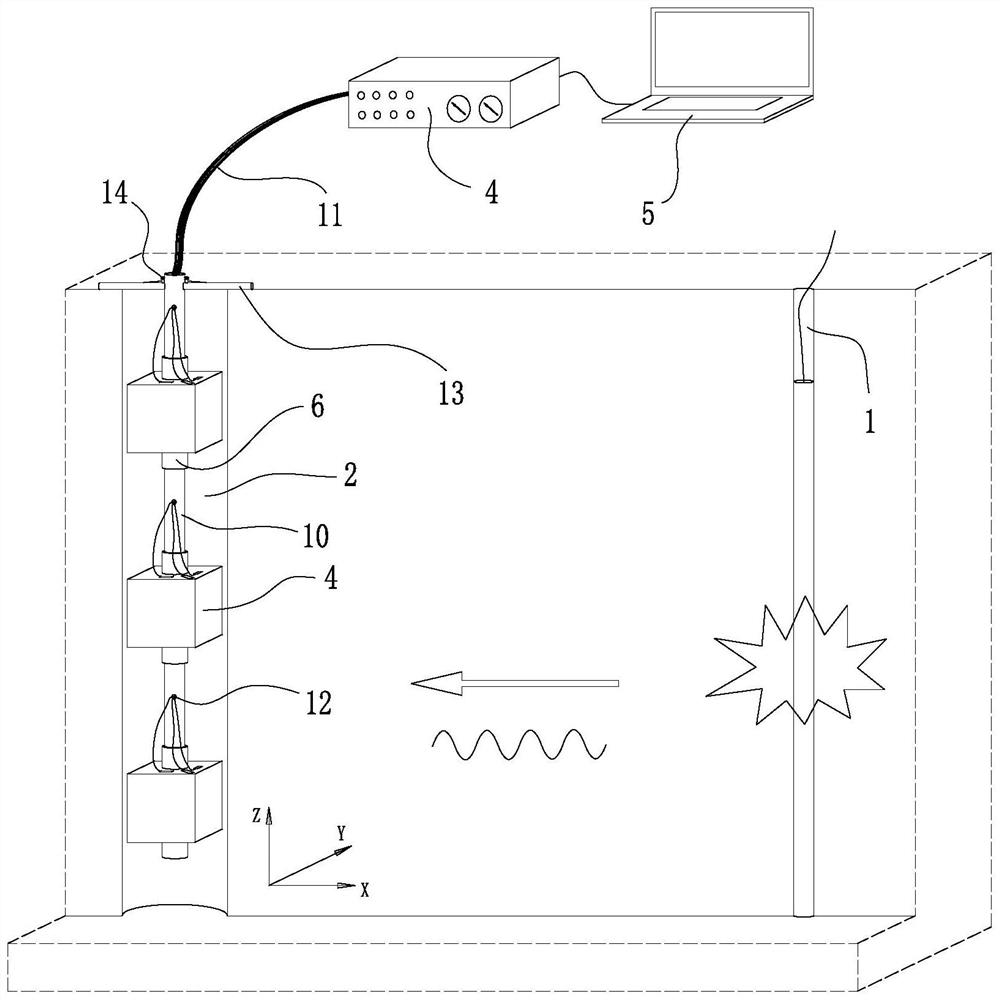

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] A method for testing dynamic strain inside a proto-rock, comprising the steps of:

[0026] Step 1: Prepare the measuring hole 2 in the area of the explosion shock wave centered on the blasting hole 1; in this embodiment, the distance between the measuring hole 2 and the blasting hole 1 is 10m, the diameter of the measuring hole 2 is 200mm, and the The depth is 2000mm;

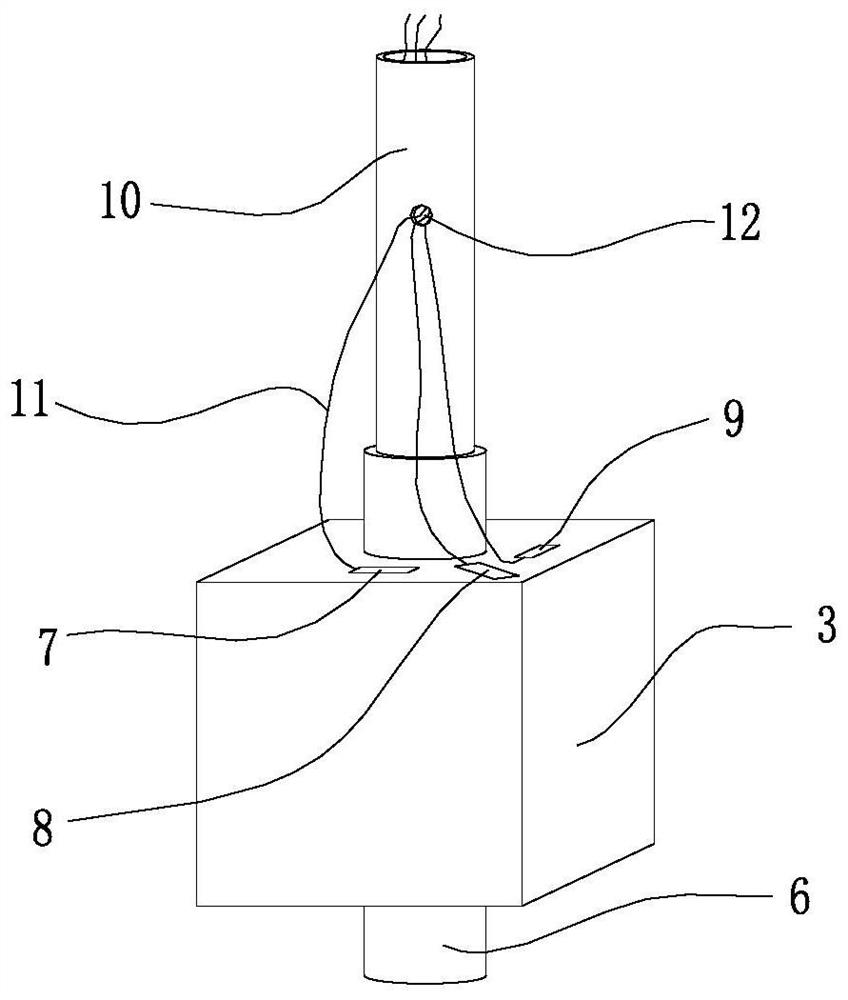

[0027] Step 2: Prepare a set of molds with cuboid cavity, pour mortar into the mold, and prepare test block 3 for simulating the physical properties of the original rock; an embedded steel pipe 6 is embedded in the prepared test block 3, and the inner The embedded steel pipe 6 is perpendicular to the upper surface and the lower surface of the test block 3, the upper end of the embedded steel pipe 6 extends out of the upper surface of the test block 3, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com