Low-NOx low-CO efficient energy-saving combustor

A high-efficiency, energy-saving, burner technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problem of low NOx burners and high CO, achieve high flue gas velocity, improve heating capacity, and reduce combustion intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

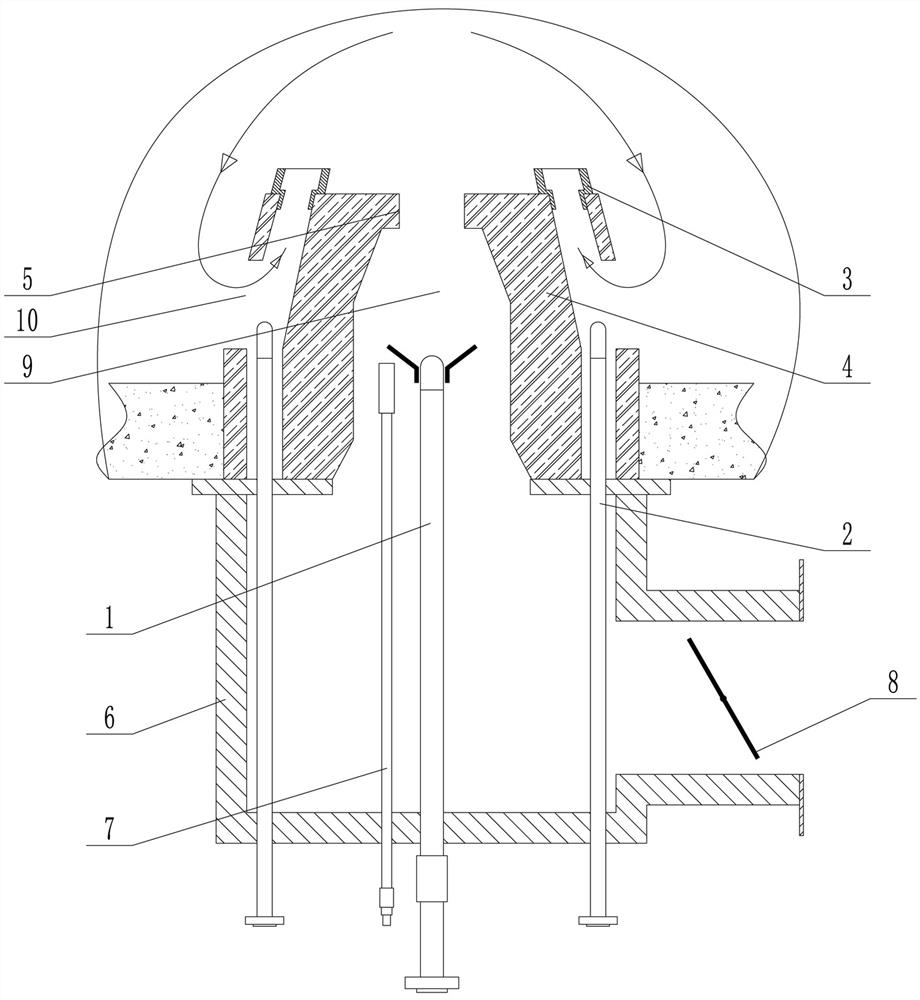

[0028] Embodiment 1, a low-NOx low-CO high-efficiency energy-saving burner, when in use, ignites the gas ejected from the main gun 1 of the burner through the ever-burning lamp 7, pre-combusts in the combustion chamber 9 to form a main flame, and passes through the burner The closing port 5 is ejected into the furnace at high speed, while the flue gas produced by the main flame flows back from the position of the flue gas return channel 10, and then flows from the belt together with the fuel gas ejected from the burner sub-lance 2 and the air pressure around the main flame. It is ejected from the position of the secondary nozzle 3 of the draft tube and enters the main flame for combustion, so that the smoke generated by the flame can be continuously mixed with the gas sprayed from the secondary nozzle 2 of the burner and then sprayed from the secondary nozzle 3 with the draft tube Combustion in contact with the main flame cools the flame temperature and effectively reduces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com