Lower shell of electric valve and its mold and production process

A technology of electric valves and shells, which is applied in the field of valve casting, can solve the problems of failure to meet the requirements of nuclear power products, failure to meet the requirements of electrical conduction, poor internal compactness of products, etc., and achieve novel and bright appearance, good electrical conductivity, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is inspired by the ideal embodiments of the present invention, and through the following description, relevant personnel can make various changes and modifications without departing from the technical idea of the present invention. The technical scope of the present invention is not limited to the content in the specification, and the technical scope must be determined according to the scope of the claims.

[0040] The present invention will be further described with reference to the following drawings:

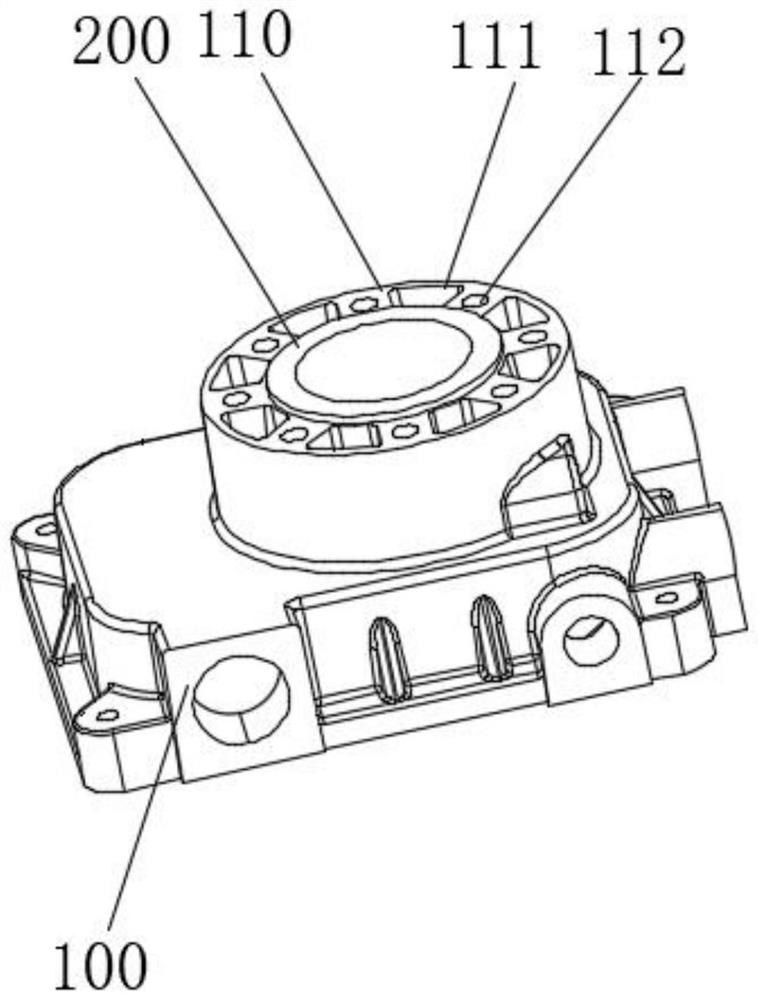

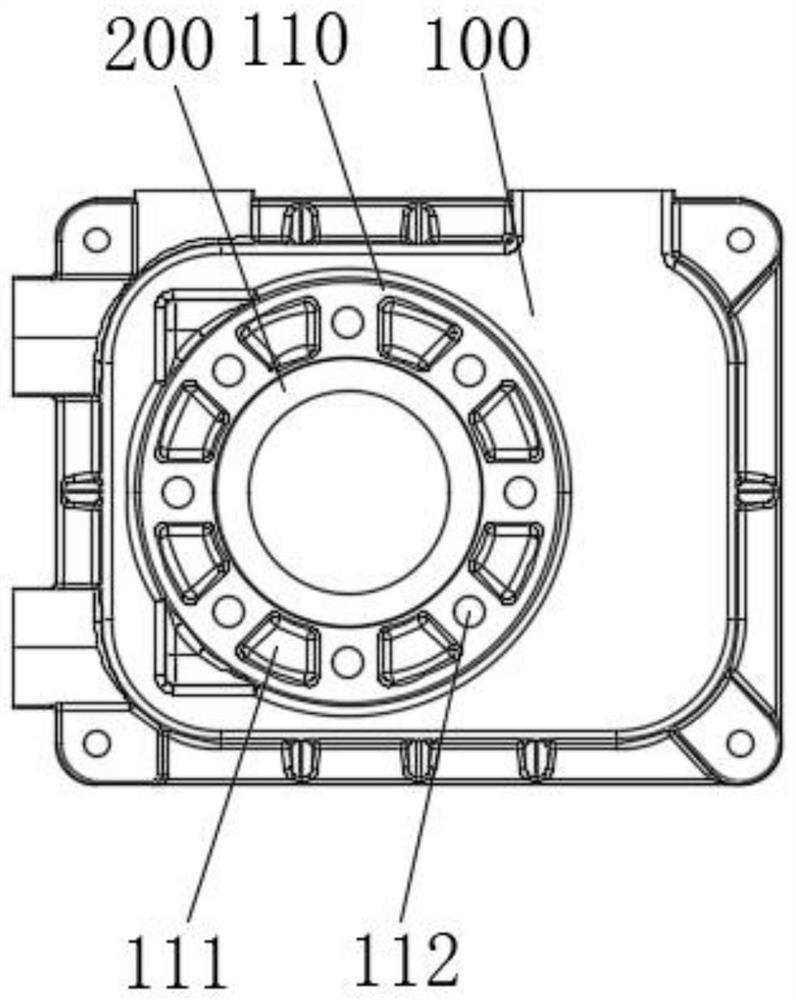

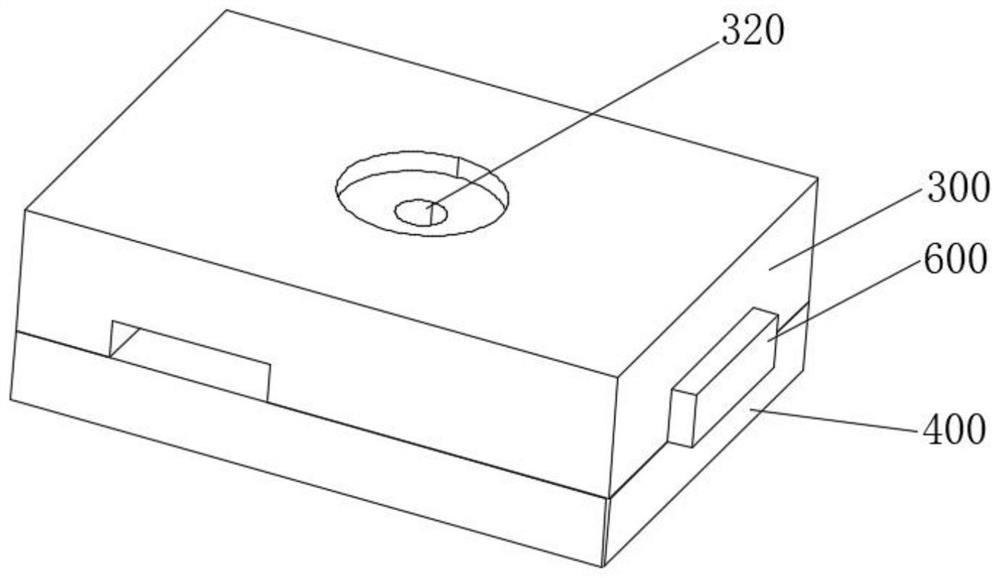

[0041] like figure 1 , 2 , 10, a lower casing of an electric valve includes a main body 100 and a copper sleeve 200, the copper sleeve 200 is embedded on the main body 100, and is integrated with the main body 100, the outer circumference of the copper sleeve 200 is provided with The continuous and discontinuous protrusions 210 are provided with a connecting portion 110 at the connection between the body 100 and the copper sleeve 200 . In addition, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com