Radiator, engine cooling system with same and engine

An engine cooling and radiator technology, applied in engine cooling, machine/engine, engine components, etc., can solve problems such as easy jamming of electric push rods, high temperature of heaters, and poor reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

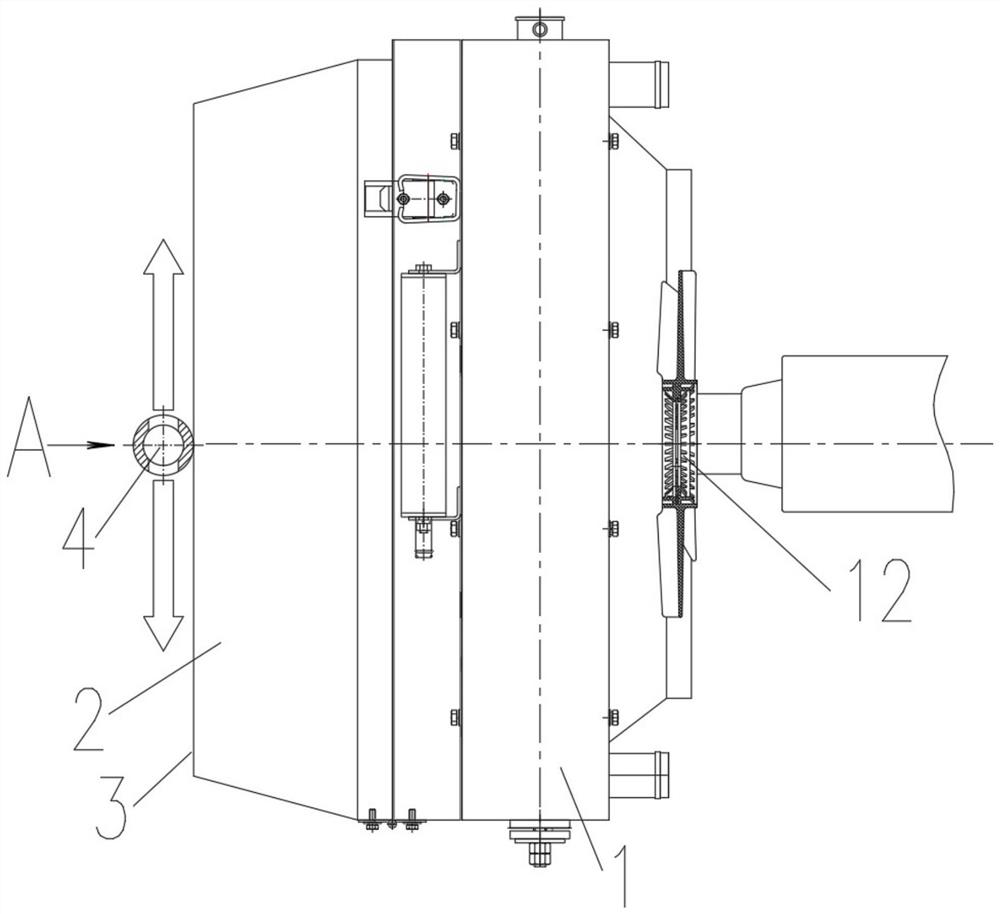

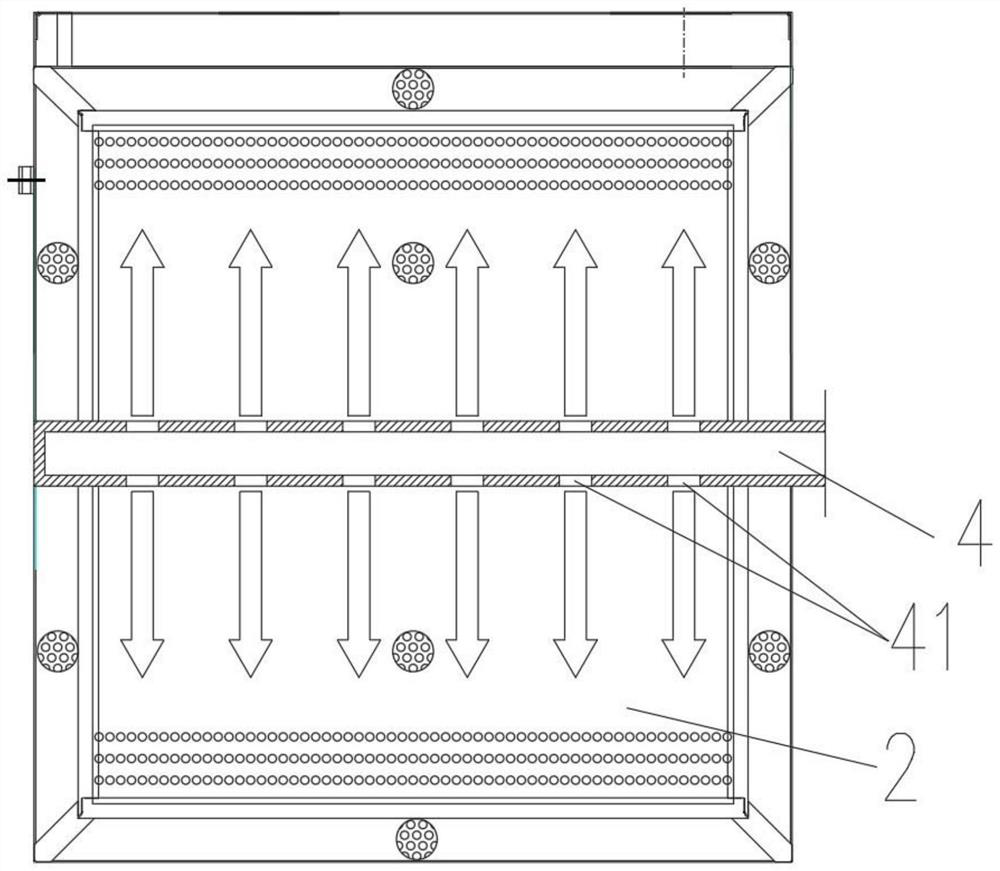

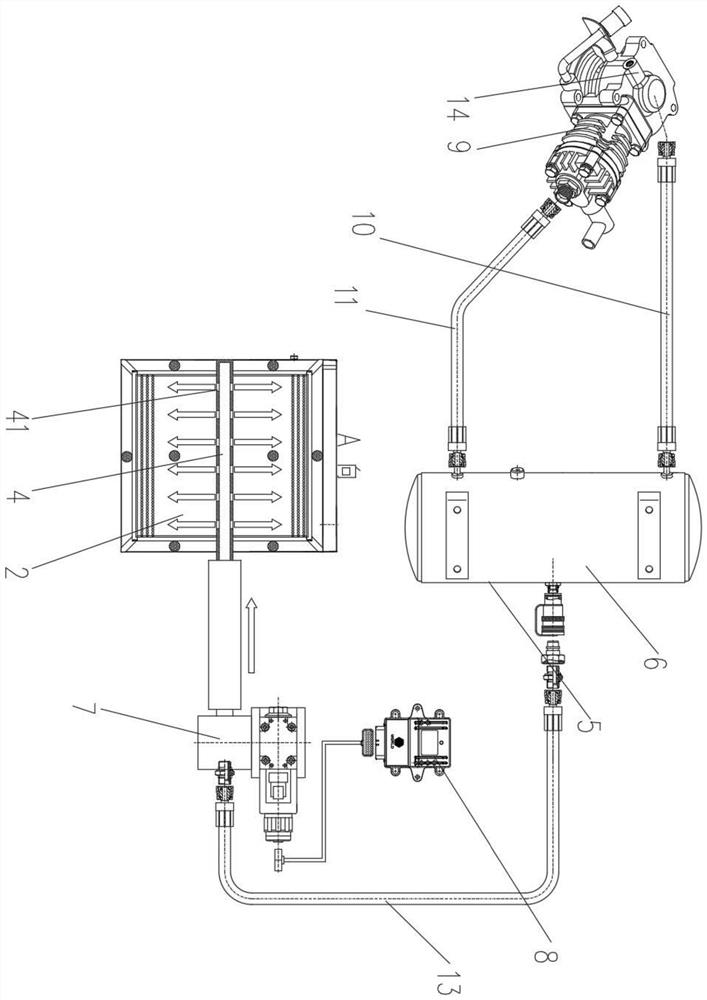

[0032] This embodiment describes a radiator, see Figure 1-Figure 3 , the radiator includes a box body 1, a net cover 2 and a cleaning device, wherein the box body 1 is a water tank, and a water circuit is arranged in it, and a fan is set on one side of the water tank, and the cooling water of the engine is cooled by using the fan. The outer side of the water tank is provided with a net cover 2, which is specifically arranged on the other side away from the fan 12 on the water tank. The net cover 2 is used to intercept the impurities adsorbed by the wind to the net cover 2 when the fan 12 cools the engine cooling water. Impurities on the intercepting surface 3, after the impurities are covered with the impurity intercepting surface 3, have a certain thickness, such as straw, bean grass and other debris, the cleaning device is used to remove impurities adsorbed on the impurity intercepting surface 3, mainly The impurity is blown away upwards and downwards along the plane direct...

Embodiment 2

[0044] This embodiment describes an engine cooling system, including a cooling circuit and the radiator described in Embodiment 1, wherein the cooling circuit circulates cooling water for the engine body, and the cooling circuit is arranged in the radiator casing 1, The engine cooling system has a good cooling effect on the engine, can be used under different working conditions, and has high reliability.

Embodiment 3

[0046] This embodiment describes an engine, which includes the engine cooling system described in Embodiment 2, and the engine can be continuously and well cooled by using the cooling system to ensure engine performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com