Drainage device provided with backstop and suitable for nuclear power station and design method of drainage device

A technology for drainage devices and backstops, which is applied to nuclear power plant auxiliary equipment, water supply devices, sewage discharge, etc., can solve the problems of waste of manpower and material resources, leaking, heavy workload, etc., and achieve cost saving, rigorous structure, and high bearing pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

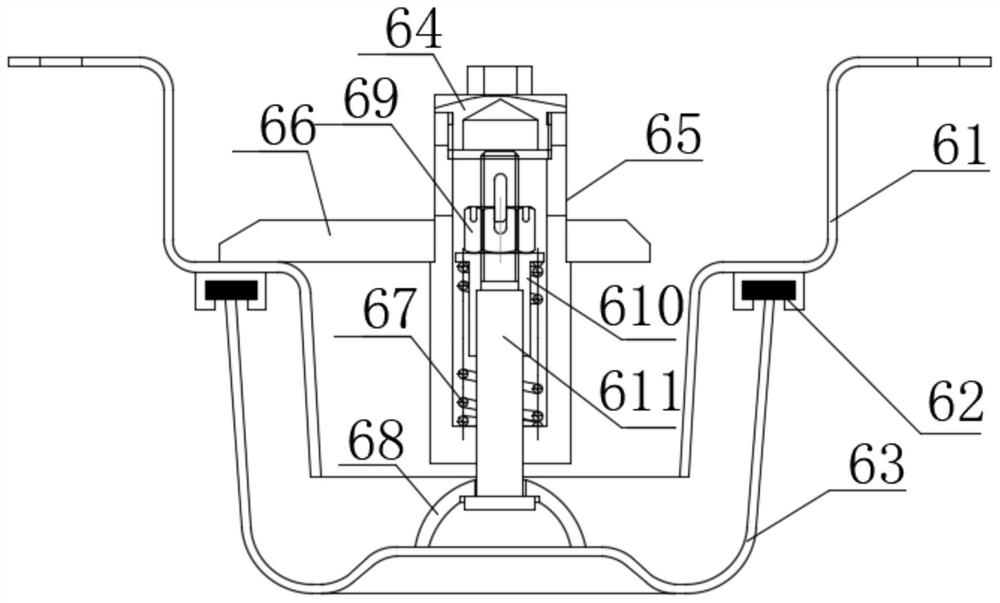

[0105] Such as Figure 1 to Figure 4 As shown, the present invention is suitable for a drainage device with a backstop for nuclear power plants, including an outer casing and a backstop 6 arranged inside the outer casing;

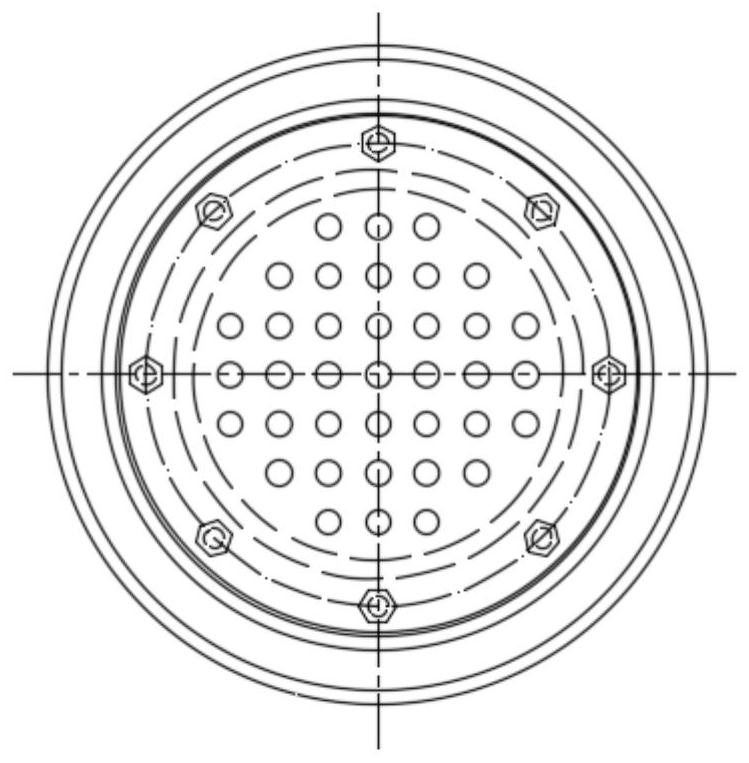

[0106]The outer casing includes a vertical main cylinder 7, the bottom of which is connected to a vertical drainage cylinder 8 through a horizontal annular connecting plate 9; the top circle of the main cylinder 7 extends outward horizontally out of the first Connecting ring, a grid plate 3 is horizontally covered on the top opening of the drainage cylinder 8 and fixed to the first connecting ring by fasteners;

[0107] A funnel 61 is fixed inside the main cylinder 7, and the funnel 61 includes a larger upper cylinder of the funnel and a lower cylinder of the smaller funnel; the bottom circle of the upper cylinder of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com