Printing ink for grainy paper, grainy paper and preparation method of grainy paper

A technology of wood grain paper and ink, applied in the direction of ink, patterned paper, application, etc., can solve the problems of poor surface gloss and wear resistance, easy uneven distribution, poor adhesion, etc., to achieve good surface flatness, Good wear resistance, the effect of improving wear resistance

Pending Publication Date: 2021-12-31

杭州博思特装饰材料有限公司

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The main component of pearlescent silver is titanium dioxide coated with silica. Because the above components have poor adhesion in the ink system, they tend to be unevenly distributed, which has a negative impact on the gloss and wear resistance of the surface.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 6

[0054] Example 6, ink for wood grain paper, differs from Example 3 in that isophorone is selected as the leveling agent.

Embodiment 7

[0055] Example 7, ink for wood grain paper, differs from Example 3 in that carboxymethyl cellulose is selected as the leveling agent.

Embodiment 8

[0056] Example 8, ink for wood grain paper, differs from Example 3 in that the solid content of the aluminum paste is 65%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

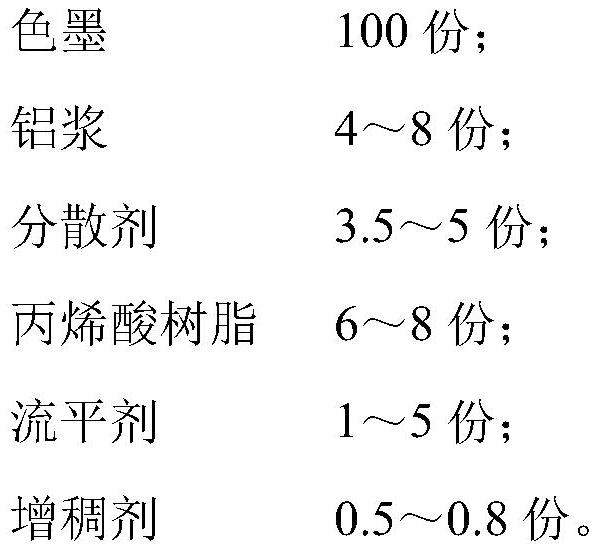

The invention relates to the field of decorative paper, in particular to grainy paper, ink for the grainy paper and a preparation method of the grainy paper. The printing ink for the grainy paper comprises color ink, aluminum paste, a dispersing agent, acrylic resin, a flatting agent and a thickening agent. The aluminum paste is adopted as a color matching agent, and the dispersing agent, the acrylic resin, the flatting agent and the thickening agent are matched, so that the grainy paper has relatively good glossiness and relatively strong wear resistance.

Description

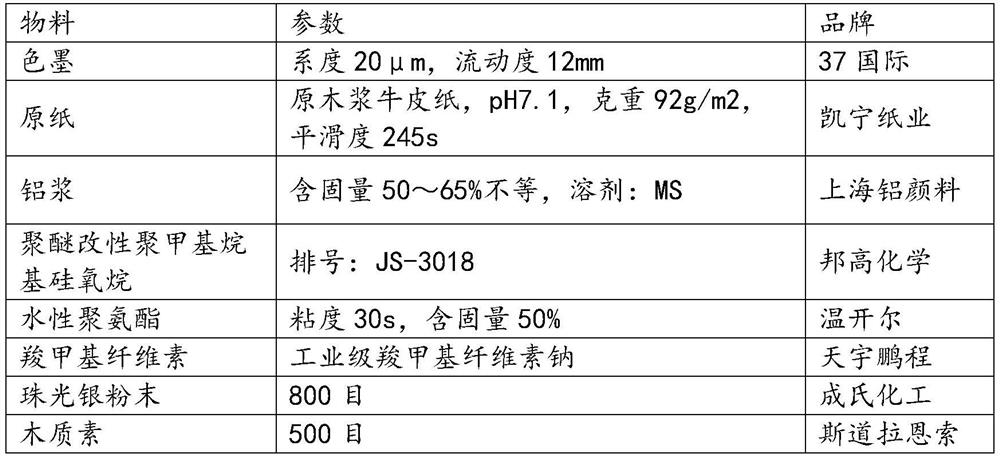

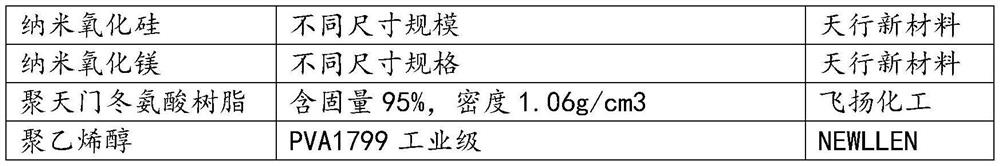

technical field [0001] The present application relates to the field of decorative paper, more specifically, it relates to an ink for wood grain paper, wood grain paper and a preparation method thereof. Background technique [0002] Wood grain paper is a commonly used decorative paper, which is widely used in interior decoration. Wood grain paper is usually obtained by printing ink on the paper surface. In order to improve the glossiness of the wood grain paper surface and form a certain metallic texture, pearlescent silver is often added to the ink of the wood grain paper to achieve a brightening effect. [0003] The main component of pearlescent silver is titanium dioxide coated with silica. Because the above components have poor adhesion in the ink system, they are easy to distribute unevenly, which has a negative impact on the gloss and wear resistance of the surface. . Contents of the invention [0004] In order to improve the glossiness and abrasion resistance of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D11/107C09D11/037C09D11/03D21H27/02D21H27/18B44C5/04B44F9/02B44F9/10D21H19/38D21H19/64D21H19/58D21H19/62D21H19/60D21H21/14D21H21/18

CPCC09D11/107C09D11/037C09D11/03D21H27/02D21H27/18B44C5/04B44F9/02B44F9/10D21H19/38D21H19/64D21H19/58D21H19/62D21H19/60D21H21/14D21H21/18

Inventor 虞立强郑军张晓波

Owner 杭州博思特装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com