Golden stamping ribbon for barcode printer and preparation method of gold stamping ribbon

A bar code printer, golden technology, applied in printing, ink ribbon, adhesive type, etc., can solve the problem of not being able to achieve the dazzling dazzling color of anodized aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for a barcode printer with hot gold tape, the method comprises the following steps:

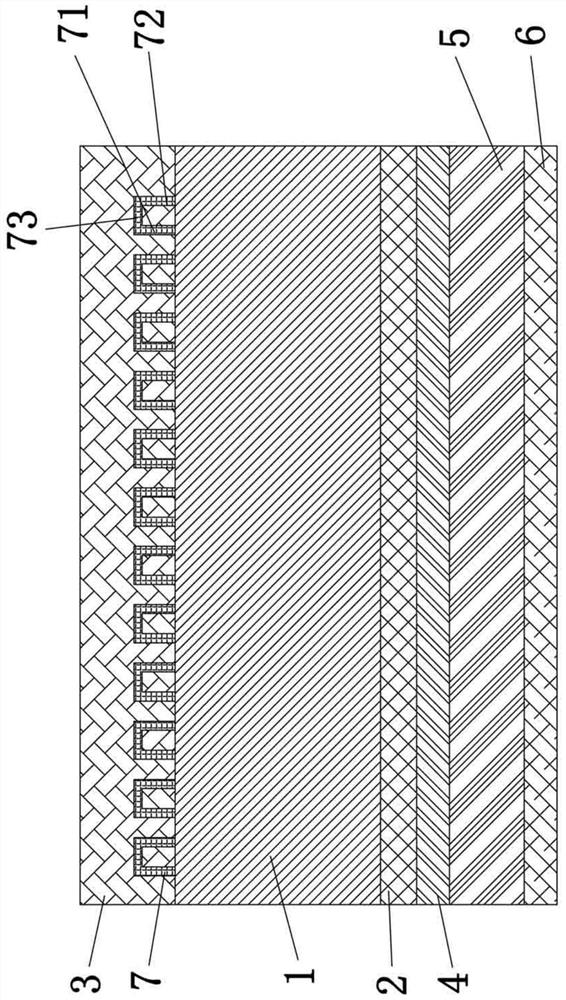

[0039] In the first step, a plurality of connecting frames 7 are evenly arranged on one of the surfaces of the base film 1, and the connecting frames 7 include a first connecting leg 71 and a second connecting leg 72, and the first connecting leg 71 and the second connecting leg 71 The lower ends of the legs 72 are correspondingly connected to the upper surface of the base film 1, and the upper ends of the first connecting legs 71 and the second connecting legs 72 are correspondingly connected to the cross bar 73;

[0040] The second step is to roll-coat the polyamideimide resin liquid on the side of the base film 1 provided with the connecting frame 7, and then dry it in a 9-meter 100-degree oven to obtain the heat-resistant layer 3;

[0041] The third step is to mix Fischer-Tropsch wax and ethylene-vinyl acetate copolymer at a mass ratio of 9:1 and heat to 130°C,...

Embodiment 1

[0049] A preparation method for a barcode printer with hot gold tape, the method comprises the following steps:

[0050]In the first step, a plurality of connecting frames 7 are evenly arranged on one of the surfaces of the base film 1, and the connecting frames 7 include a first connecting leg 71 and a second connecting leg 72, and the first connecting leg 71 and the second connecting leg 71 The lower ends of the legs 72 are correspondingly connected to the upper surface of the base film 1, and the upper ends of the first connecting legs 71 and the second connecting legs 72 are correspondingly connected to the cross bar 73;

[0051] In the second step, the polyamide imide resin liquid roll is applied to the side of the base film 1 provided with the connecting frame 7, and then dried in a 9-meter 100-degree oven to obtain a heat-resistant layer 3; The amine resin is Toyobo HR-11NN.

[0052] The third step is to mix Fischer-Tropsch wax and ethylene-vinyl acetate copolymer at a...

Embodiment 2

[0058] A preparation method for a barcode printer with hot gold tape, the method comprises the following steps:

[0059] In the first step, a plurality of connecting frames 7 are evenly arranged on one of the surfaces of the base film 1, and the connecting frames 7 include a first connecting leg 71 and a second connecting leg 72, and the first connecting leg 71 and the second connecting leg 71 The lower ends of the legs 72 are correspondingly connected to the upper surface of the base film 1, and the upper ends of the first connecting legs 71 and the second connecting legs 72 are correspondingly connected to the cross bar 73;

[0060] In the second step, the polyamide imide resin liquid roll is applied to the side of the base film 1 provided with the connecting frame 7, and then dried in a 9-meter 100-degree oven to obtain a heat-resistant layer 3; The amine resin is Toyobo HR-11NN.

[0061] The third step is to mix Fischer-Tropsch wax and ethylene-vinyl acetate copolymer at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com