Synthesis method of 2-(2-methoxyphenoxy)ethylamine

The technology of a methoxyphenoxy group and a synthesis method is applied in the synthesis field of 2-ethylamine, and can solve the problems of long reaction route, high production cost, expensive reaction reagents and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

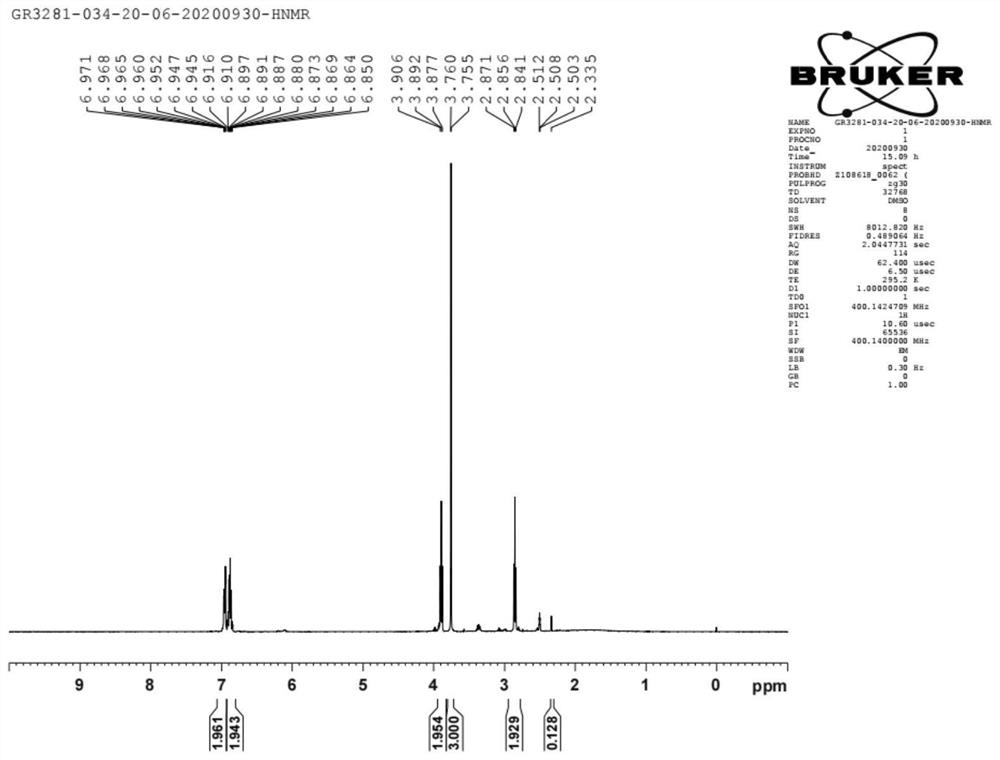

[0027] Preparation of 2-(2-methoxyphenoxy)ethylamine:

[0028] Add guaiacol (12.41g, 0.1mol), urea (9.60g, 0.16mol), ethanolamine (9.76g, 0.16mol) and potassium hydroxide (2.80g, 0.05mol) to a 250ml single-necked bottle, and heat at 120°C , program temperature rise to 170°C (10°C every half hour), keep warm for 6h, add ethylenediamine (3.00g, 0.05mol), continue heating at 170°C for 2h, add 50ml water to the reaction product after cooling to dissolve, concentrated Adjust the pH to 2 with hydrochloric acid, filter, add 50 ml of chloroform to the water layer and wash once, adjust the pH to 13 with 20% sodium hydroxide solution, add 50 ml of chloroform for extraction, distill off the chloroform under reduced pressure to obtain 11.4 g of a brownish black liquid, the purity of which is 52.9% by GC , yield 36.1%.

Embodiment 2

[0030] Preparation of 2-(2-methoxyphenoxy)ethylamine:

[0031] Add guaiacol (12.41g, 0.1mol), urea (9.60g, 0.16mol), ethanolamine (9.76g, 0.16mol), potassium hydroxide (0.56g, 0.01mol) to a 250ml single-mouth bottle, add 50ml Dissolve trimethylbenzene, heat at 120°C, program temperature rise to 170°C (10°C per hour), keep warm for 15 hours, add ethylenediamine (3.00g, 0.05mol), heat at 170°C for 2h, add 50ml of water to the reaction product after cooling Dissolve, adjust pH=2 with concentrated hydrochloric acid, filter, add 50ml chloroform to the aqueous layer, wash once, adjust pH=13 with 20% sodium hydroxide solution, add 50ml chloroform for extraction, evaporate chloroform under reduced pressure, and obtain 12.7g brownish black liquid, purity 97.0 %, yield 73.4%.

Embodiment 3

[0033] Preparation of 2-(2-methoxyphenoxy)ethylamine:

[0034] Add 30ml of mesitylene, guaiacol (12.41g, 0.1mol), urea (9.60g, 0.16mol), ethanolamine (9.76g, 0.16mol) and potassium hydroxide (0.56g, 0.01mol) to a 250ml single-necked bottle ), heated at 120°C, programmed to heat up to 170°C (10°C every half hour), keep warm for 20h, add ethylenediamine (3.00g, 0.05mol), heat at 170°C for 2h, add 50ml of water to the reaction product after cooling to dissolve, Concentrated hydrochloric acid to adjust pH=2, filter, add 50ml chloroform to the water layer, wash once, adjust pH=13 with 20% sodium hydroxide solution, add 50ml chloroform for extraction, evaporate chloroform under reduced pressure to obtain 11.6g brownish black liquid, purity 87.3 by GC %, yield 60.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com