Concrete maintenance device for water conservancy construction

A concrete and water conservancy technology, which is applied in the field of concrete curing devices for water conservancy construction, can solve problems such as lack of cohesive force, inability to transform crystallization, inconvenience of overall movement, etc., to achieve the effect of ensuring movement stability and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

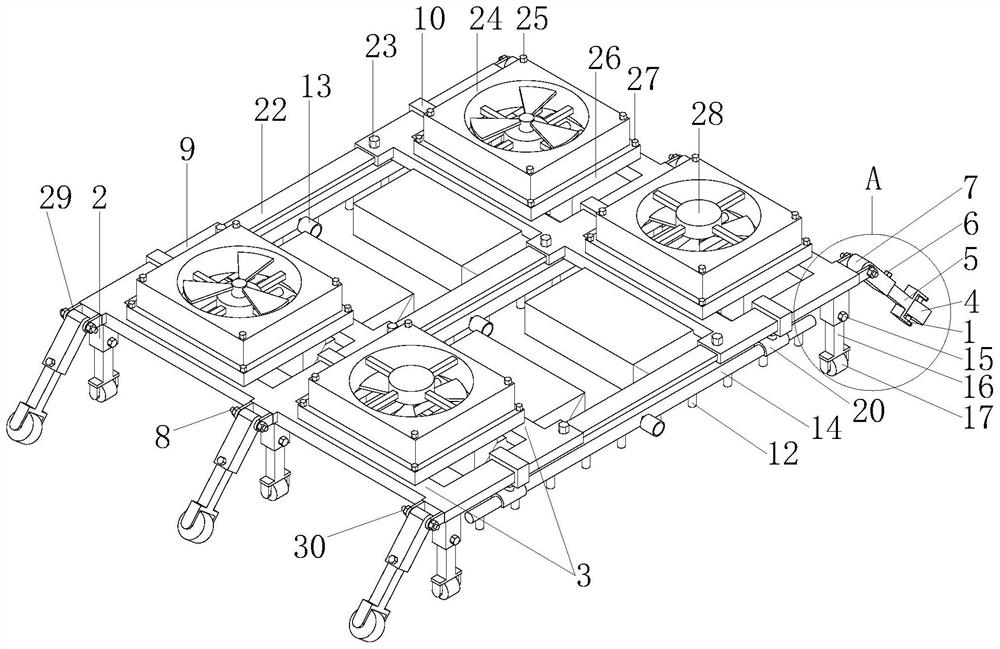

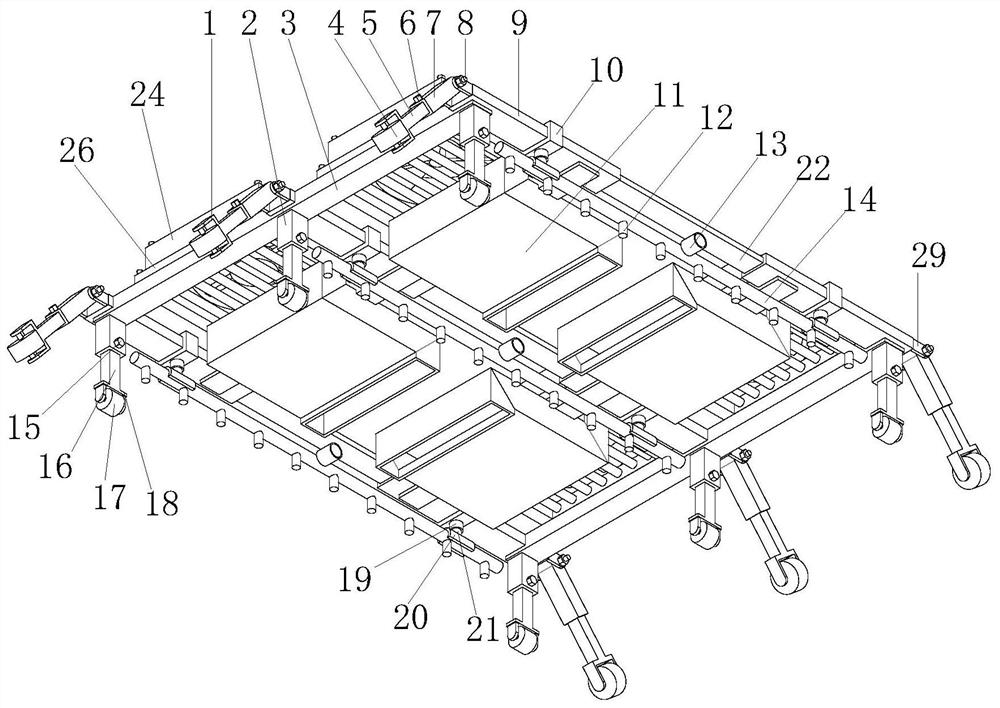

[0020] Such as Figure 1-4 As shown, a concrete maintenance device for water conservancy construction proposed by the present invention includes six symmetrical telescopic sleeves 9, telescopic rods 22 are slidably connected between the relative telescopic sleeves 9, and the telescopic sleeves 9 are threaded with bolts C23, bolts C23 Through the telescopic sleeve 9 and abut against the telescopic rod 22, a crossbar 3 is connected between the parallel telescopic sleeves 9, and the upper end of the crossbar 3 and the telescopic sleeve 9 is detachably connected with four evenly distributed heating devices 26, the heating device 26 The lower end communicates with an air duct 11, and the end of the air duct 11 away from the heating device 26 is set under the telescopic rod 22. The upper end of the heating device 26 can be detached with two sets of symmetrical exhaust fans 24 and intake fans 28, and the exhaust fans 24 and intake fans There are two fans 28 respectively and the posit...

no. 2 example

[0024] Such as Figure 1-4 As shown, the invention proposes a concrete maintenance device for water conservancy construction. Compared with the first embodiment, the sliding adjustment device A in this embodiment includes a sliding sleeve A2, a sliding rod A16, a bolt A15, a bracket A18 and a pulley A17 The upper end of the sliding sleeve A2 is connected to the telescopic sleeve 9, the sliding sleeve A2 is slidably connected to the slide bar A16, the slide bar A16 is connected to the support A18, the support A18 is rotated and connected to the pulley A17, and the sliding adjustment device A can adjust the height of the slide bar A16 according to the on-site ramp, ensuring The whole installation is level with the ramp of the hydraulic works.

no. 3 example

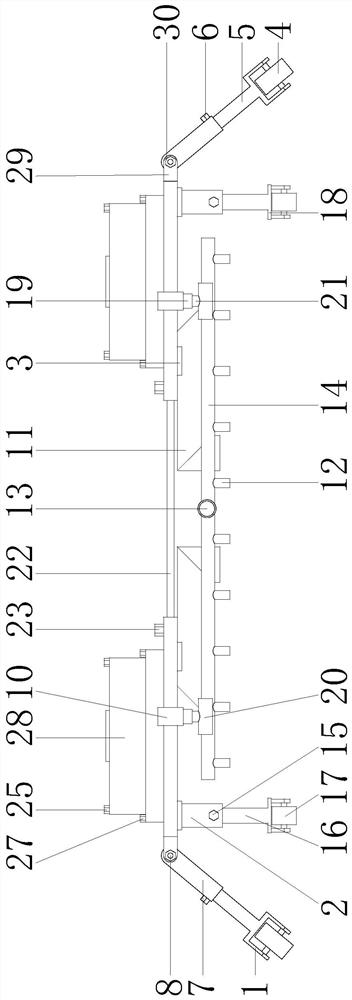

[0026] Such as Figure 1-4 As shown, a concrete maintenance device for water conservancy construction proposed by the present invention, compared with the first embodiment or the second embodiment, the side end of the telescopic sleeve 9 in this embodiment is connected with a fixed frame 29, and the fixed frame 29 rotates Connected with threaded rod 8, the two ends of threaded rod 8 all pass through fixing frame 29 and threaded connection nut 30, lock or loosen threaded rod 8 by nut 30, thereby guarantee the fixing and loosening of threaded rod 8.

[0027] The sliding adjustment device B includes a sliding sleeve B7, a sliding rod B5, a bolt B6, a bracket B1 and a pulley B4; the part of the threaded rod 8 between the fixed frames 29 is connected with the sliding sleeve B7, and the sliding sleeve B7 is slidably connected with the sliding rod B5, and the sliding rod B5 is connected with bracket B1, and bracket B1 rotates to connect with pulley B4. The sliding adjustment device B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com