Deep-sea high-power low-vibration motor direct-drive propelling device

A propulsion device, high-power technology, applied in the direction of propulsion device engine, electromechanical device, ship propulsion, etc., to achieve the effect of large application prospects, light weight, and simple integration and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

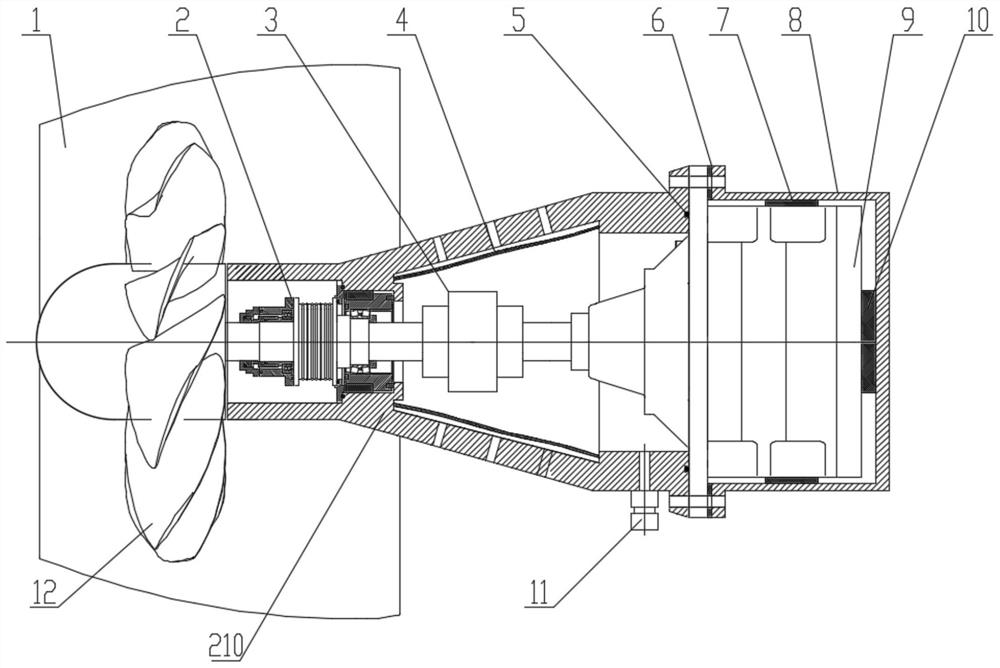

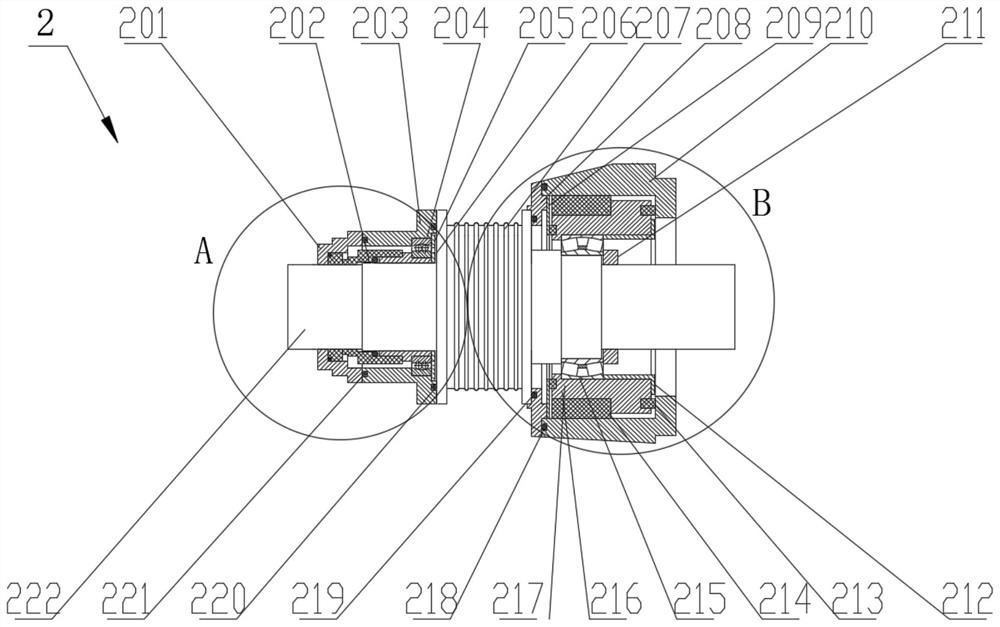

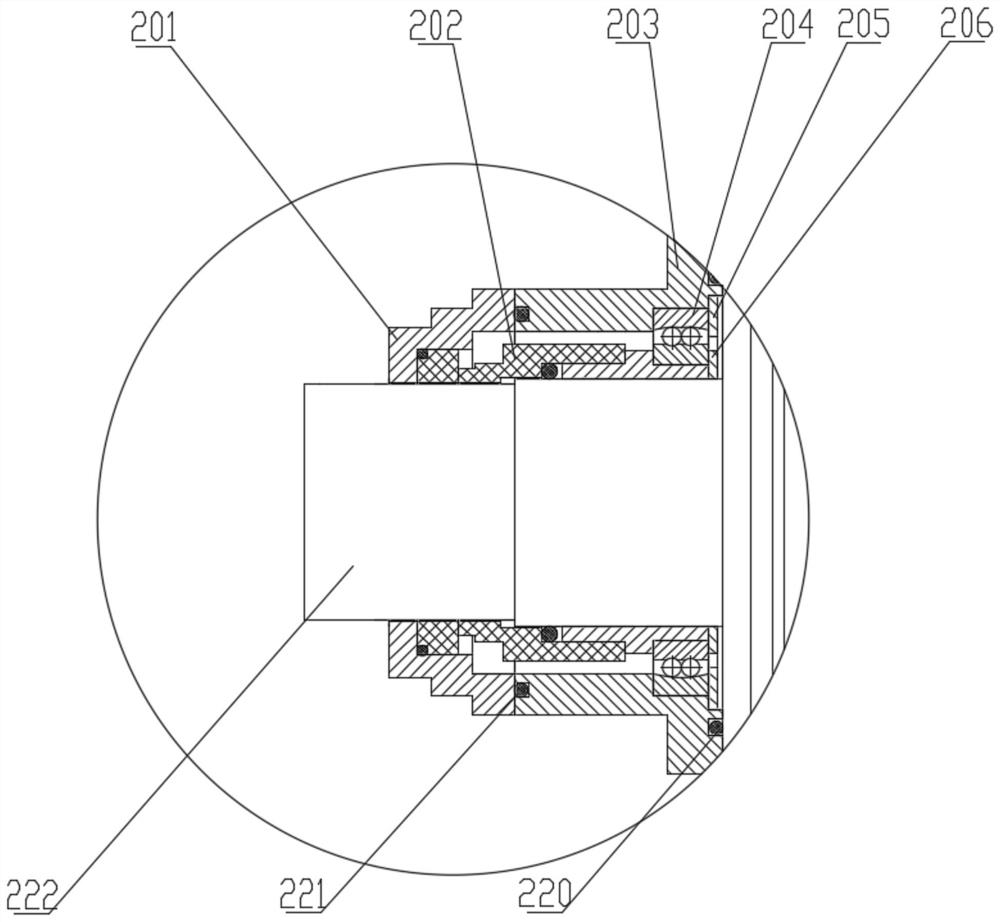

[0028] Such as Figure 1-Figure 4 As shown, the deep-sea high-power low-vibration motor direct-drive propulsion device of this embodiment includes a propeller 1, and the propeller 1 is fixedly connected with the propulsion motor 9 through a conduit fixing flange cap 210, and the end face of the conduit fixing flange cap 210 is connected to the The flanges of the propulsion motor 9 are sealed by a No. 1 O-shaped sealing ring 5, and the exterior of the propulsion motor 9 is equipped with a soundproof cover 8, and a vibration isolation sealing gasket 6 is installed between the soundproof cover 8 and the flange of the propulsion motor 9. A No. 1 vibration isolation ring 7 and a No. 2 vibration isolation ring 10 are arranged between the soundproof cover 8 and the propulsion motor 9; the output end of the propulsion motor 9 is connected to a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com