Track flat car with adjustable load bearing and automatic braking functions

A rail flat car and automatic braking technology, which is applied in the direction of railway car bodies, transport passenger cars, railway braking systems, etc., can solve the problems of limited load-bearing capacity of rail flat cars, inability to transport construction equipment, and inability to adjust construction equipment, so as to save loading and unloading time , quick installation and dismantling, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Example: Please refer to Figure 1 to Figure 13 :

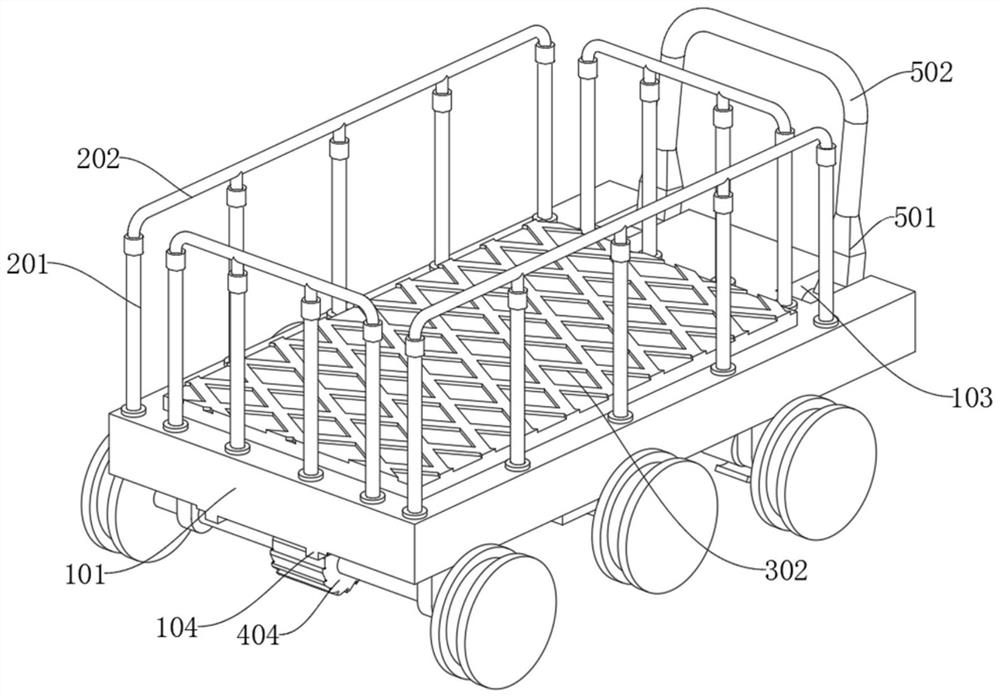

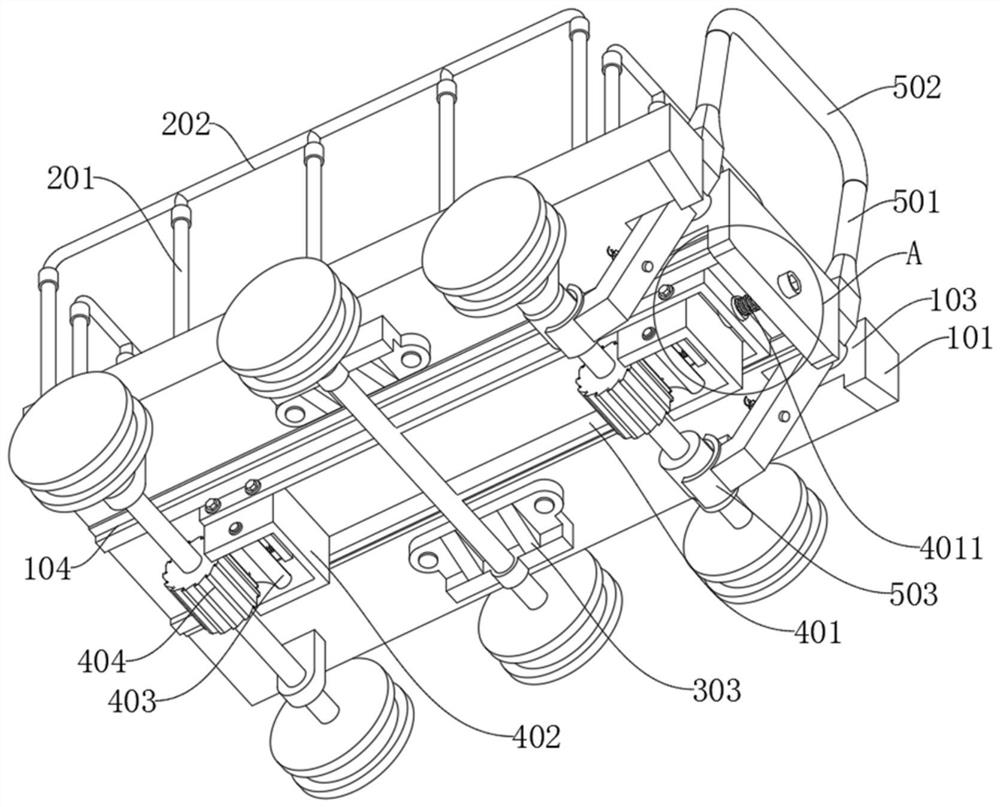

[0071] The present invention proposes a rail platform car with adjustable load-bearing and automatic braking functions, including a mounting part 1;

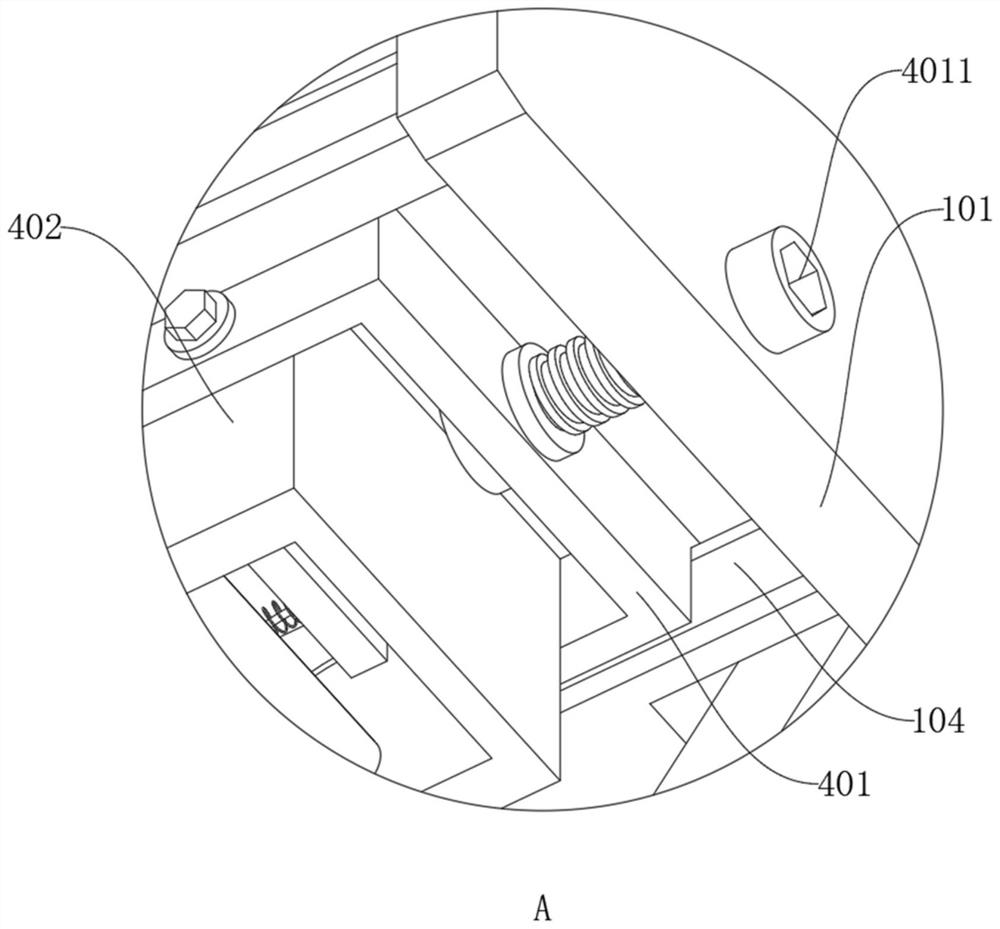

[0072] The mounting part 1 includes: a mounting plate 101, the mounting plate 101 is a square plate structure, the top of the mounting plate 101 is provided with a rectangular groove, the front and rear sides of the rectangular groove of the mounting plate 101 are connected with rectangular grooves, the mounting plate 101 The bottom of the rectangular groove is connected with a circular through hole, and the left and right ends of the rear side of the mounting plate 101 are provided with an arc tubular structure, and the arc tube of the mounting plate 101 is provided with a return spring, and the bottom of the mounting plate 101 is provided with a movable Wheel; the mounting plate 101 is used for installing and fixing other structures of the device; the protective part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com