Guardrail punching machine

A punching machine and guardrail technology, applied in the field of stamping equipment, can solve problems such as poor convenience of guardrails, and achieve the effects of improving convenience, reducing pulling strength, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

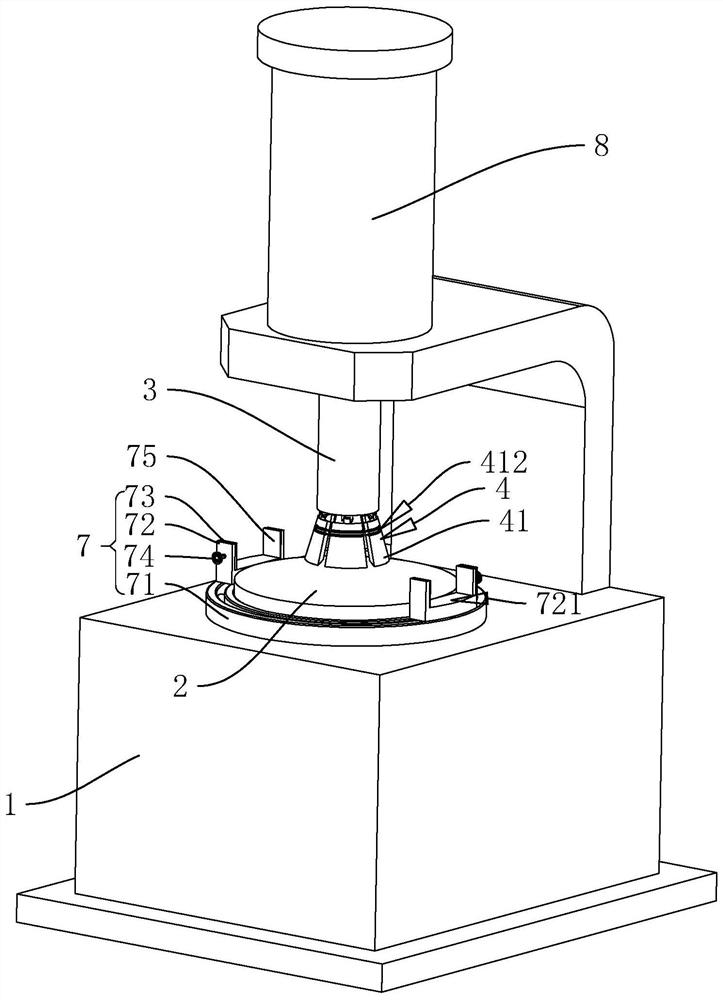

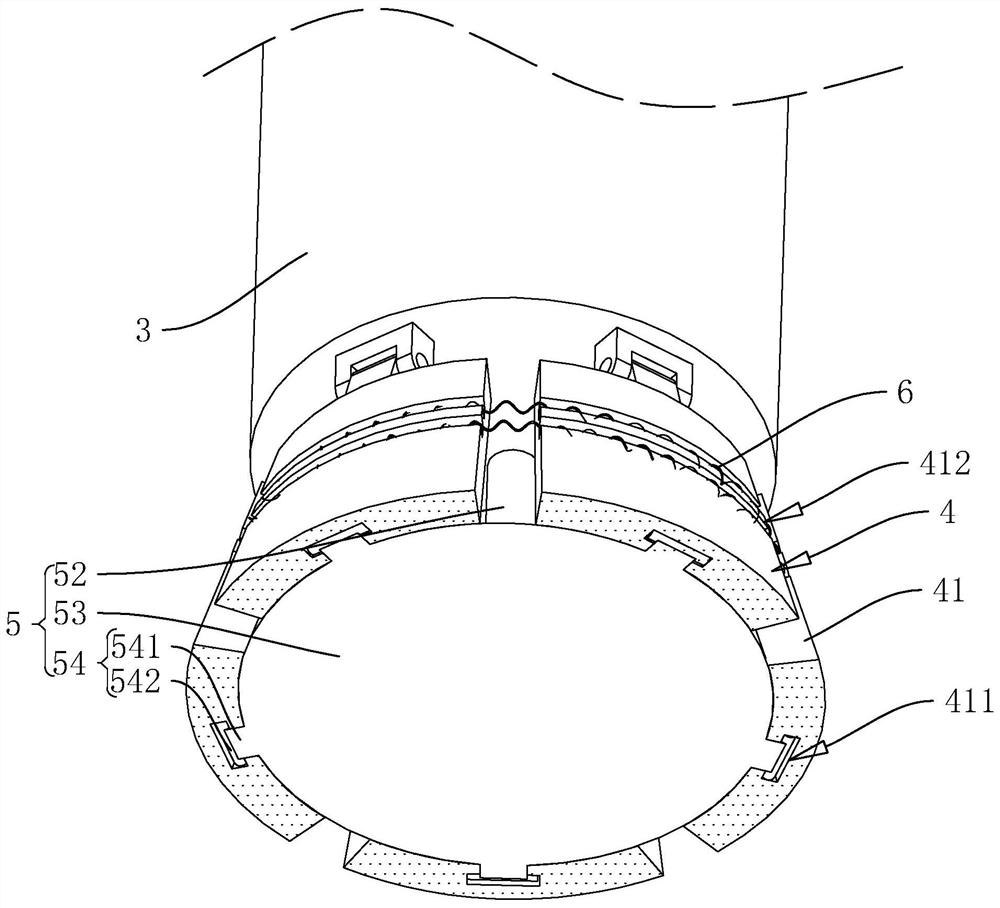

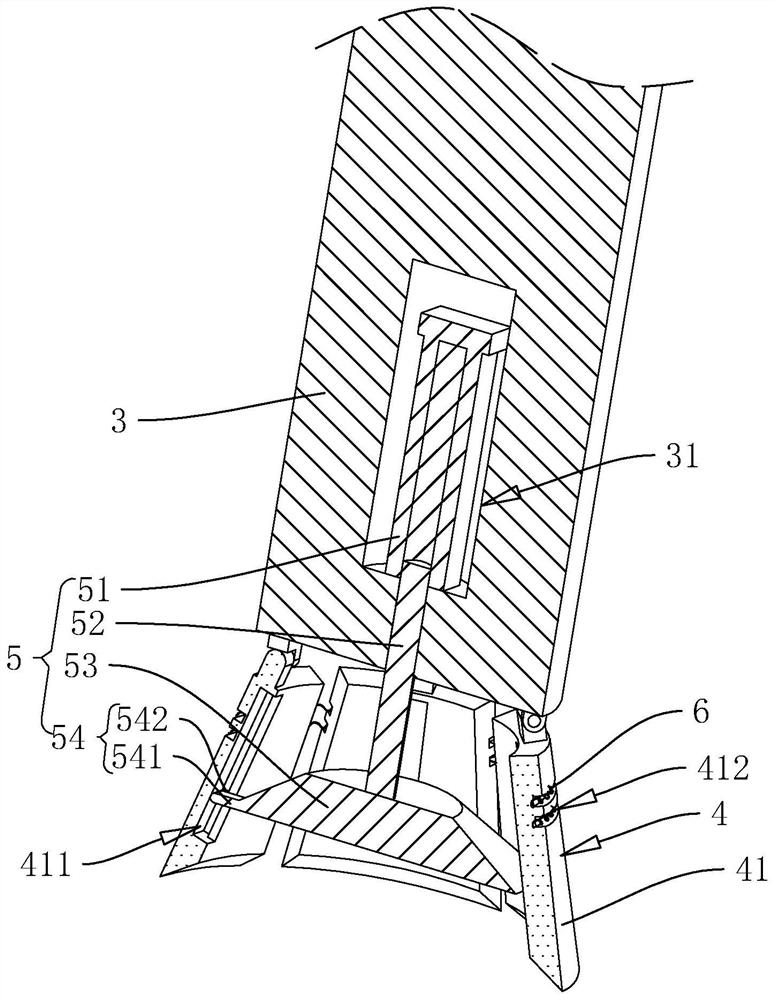

[0033] Contraction below Figure 1-5 Further detailed description of the present application.

[0034] Example punch discloses a guardrail of the present application. Refer figure 1 , figure 2 and image 3 Guardrail punching machine comprises a frame 1, two pressure units, three punch, punch driving assembly 5 and the ring 4, the frame 1 is provided vertically, a cylindrical pressure stage 2, stage 2 vertically disposed pressure , pressure stage 2 and the frame 1 are integrally formed, punch 3 positioned above the frame 1, the frame 3 and the punch 1 sliding connection, 3 is also cylindrical punch, punch station 3 and the bearing 2 arranged coaxially, pressure punch 3 positioned at the top table 2, is provided with a punch press cylinder 8, the vertical press cylinder 8 is provided between the chassis 1 and 3, the press and the frame 8 of the cylinder housing 1 by means of bolted connections, stamping cylinder 8 and a ram piston rod 3 integrally formed; punching punch knife ring 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com