Steel member data processing system

A data processing system and steel component technology, which is applied to machine tools, grinders, and metal processing equipment suitable for grinding the edge of workpieces, can solve the problems of hidden dangers, time-consuming and labor-intensive installation of workers, and achieve stable lifting, increased stability, and increased The effect of the stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

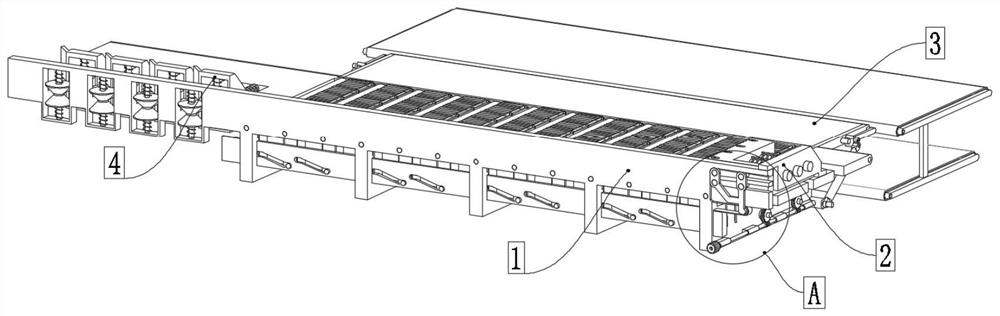

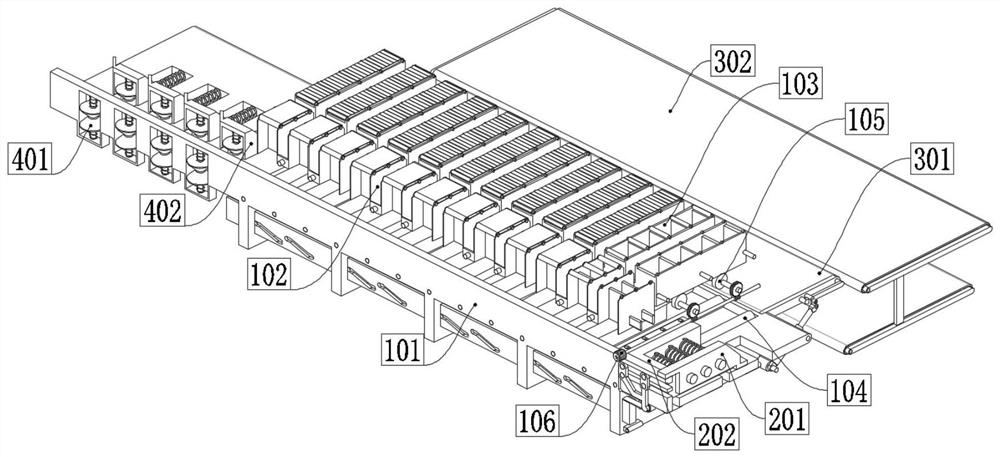

[0050] as attached figure 1 to attach Figure 10 Shown:

[0051] The invention provides a steel component data processing system, including a production platform 1;

[0052] Production platform 1, the production platform 1 is a horizontal frame structure, the right end of the production platform 1 is provided with a steering structure 2, and the left end of the production platform 1 is installed with four sets of chamfering components 4, the chamfering components 4 include: guide wheels 401, guide The wheel 401 has a funnel structure, and the outer wall of the guide wheel 401 is made of a grinding wheel. Through the guide wheel 401 of the funnel structure, better contact with the steel water chestnut is achieved. By setting the outer wall of the guide wheel 401 as a grinding wheel structure, it is realized. For the polishing of corners, four sets of guide wheels 401 are rotated on the long slot at the left end of the mounting frame 101; the sliding frame 402, the sliding fra...

no. 2 example

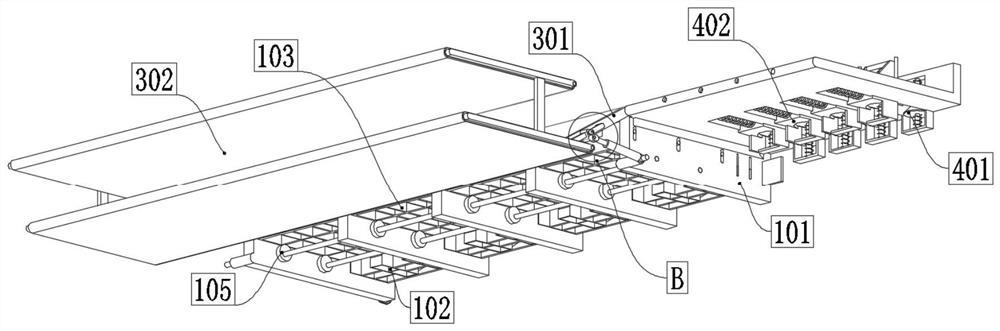

[0071] Wherein, material distribution device 3 includes:

[0072] The material distribution plate 301 is hingedly installed at the rear end of the installation frame 101, and the outer wall of the material distribution plate 301 is equipped with a conveyor belt. The material distribution plate 301 installed through the hinge is conducive to the subsequent classification of steel materials of different sizes by the equipment;

[0073]Conveyor belt 302, conveyer belt 302 is arranged in two layers altogether, through the conveyer belt 302 of two-layer structure, has realized the effect to steel material classification effectively, top conveyer belt 302 and installation frame 101 are on the same horizontal line, bottom conveyer belt 302 is longer than The top conveyor belt 302, through the conveyor belt 302 at the same horizontal line as the top and the installation frame 101, is conducive to the direct delivery of the steel by the material distribution plate 301, and the conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com