Ammonia desulfurization method and ammonia desulfurization device

A technology of ammonia-based desulfurization and desulfurizer, applied in separation methods, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of high investment and operation costs, complex desulfurization tower system, etc., reduce investment, eliminate flue gas drag Tail phenomenon and generation of aerosol, effect of simplifying process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

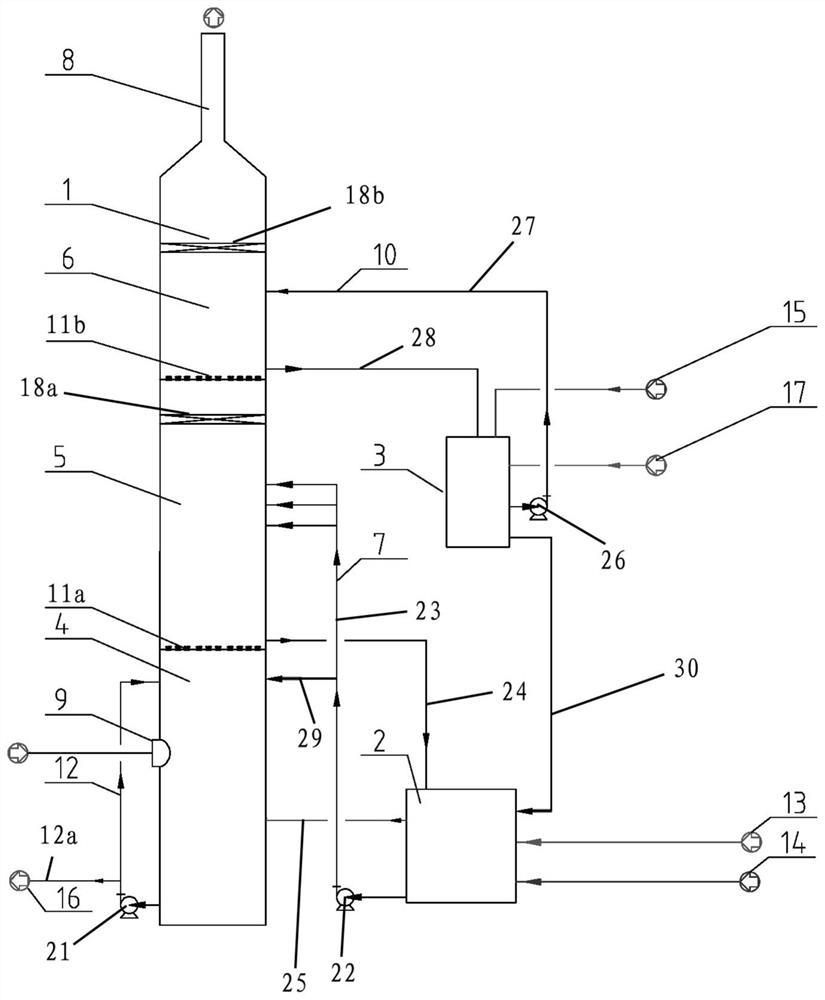

[0067] figure 1 Shows an exemplary embodiment according to the present invention ammonia desulfurization apparatus. The ammonia desulfurization flue gas treating means may be used for coal-fired boilers of power plant, or may be used for other chemical processing flue gas containing sulfur oxides. In the present invention relates to a desulfurization process of ammonia Unlike traditional pure ammonia desulfurization, but based on the additional ammonia desulfurization utilizing alkaline metal desulfurizing agent.

[0068] The ammonia desulfurization apparatus comprising an ammonia desulfurization tower, the ammonia desulfurization tower from bottom to top comprises a flue gas cooling unit 4, unit 5 and the flue gas absorption fine particulate control unit 6. Flue gas cooling unit 4 has an inlet flue 9. Containing SO 2 And SO 3 Flue gas, as a raw gas, generally have a higher temperature, into the flue gas flue gas cooling unit 4 via the inlet 9. Flue gas cooling unit 421 are forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com