Shale gas horizontal well osculating fracturing perforation parameter optimization design method

An optimized design, horizontal well technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems of unstable application effect, lack of theoretical basis, unsatisfactory application effect, etc., and achieve simple and intuitive thinking and theoretical basis. The effect of perfect and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

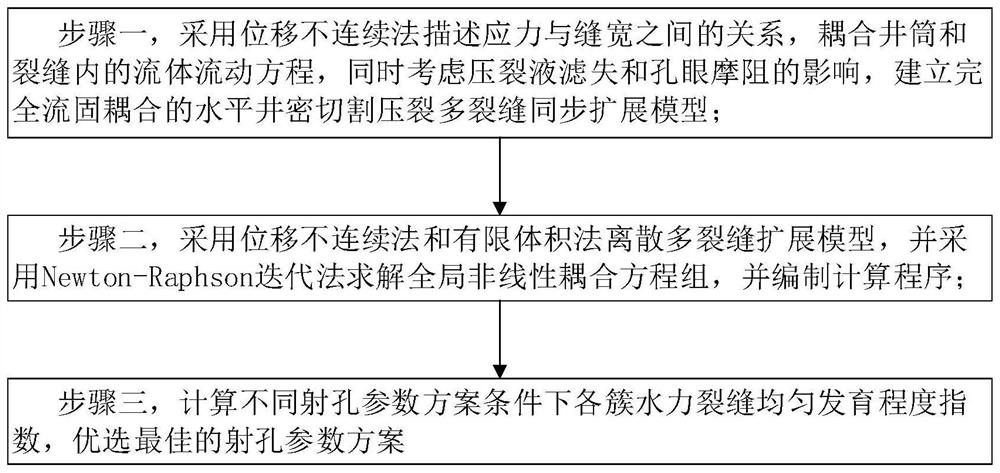

Method used

Image

Examples

Embodiment 1

[0152] Example 1: Optimal design of isodensity perforation parameters.

[0153] Taking the shale gas horizontal well FYH1 in the Fuling block as an example, the reservoir drilling rate of this well is high, and the horizontal section basically runs through the same set of reservoirs. When carrying out the fracturing design, it is assumed that the reservoir conditions in the whole well section are homogeneous, and the stress conditions in the same fracturing section are consistent. It is planned to divide 21 sections into dense cutting fracturing, adopt the equal-density perforation method, and perforate 5 to 7 clusters in a single section. The cluster spacing is 7m, and a perforating gun with a 9.5mm aperture is used to carry out the operation. Other basic parameters are shown in Table 1 below. A shale gas horizontal well dense cutting fracturing perforation parameter optimization design method, including the following steps in sequence:

[0154] Table 1 Basic parameters of W...

Embodiment 2

[0161] Example 2: Optimal design of non-isodensity perforation parameters.

[0162] In Example 1, the perforation scheme with 5 holes per cluster has obvious effects on improving the unbalanced expansion of hydraulic fractures in each cluster in the fracturing section, but the production profile test results ( Figure 4 ) indicates that the toe clusters (13th, 15th, 17th fracturing stages) and middle clusters (10th, 11th, 12th, 14th fracturing stages) still have poor hydraulic fracture development in some fracturing stages. Inter-stress interference and intra-section stress heterogeneity, in order to improve this adverse effect, it is necessary to adopt a non-isodensity perforation scheme, increase the number of perforation clusters with poorly developed hydraulic fractures, and further improve the hydraulic pressure of each cluster in the section. Non-equilibrium crack expansion problem. In view of the above problems, in Embodiment 2 of the present invention, the 15th and 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracturing fluid viscosity | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com