Preparation method of high-substitution-degree octenyl succinic acid modified starch

A technology of octenyl succinic anhydride ester and octenyl succinic acid, which is applied in the field of preparation of high-substitution octenyl succinic acid starch ester, can solve the problems of difficulty in meeting the needs of industrial production, low reaction efficiency of aqueous phase method, and environmental pollution Large and other problems, to achieve good emulsion properties and the ability to embed substances, improve esterification efficiency, and enhance the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

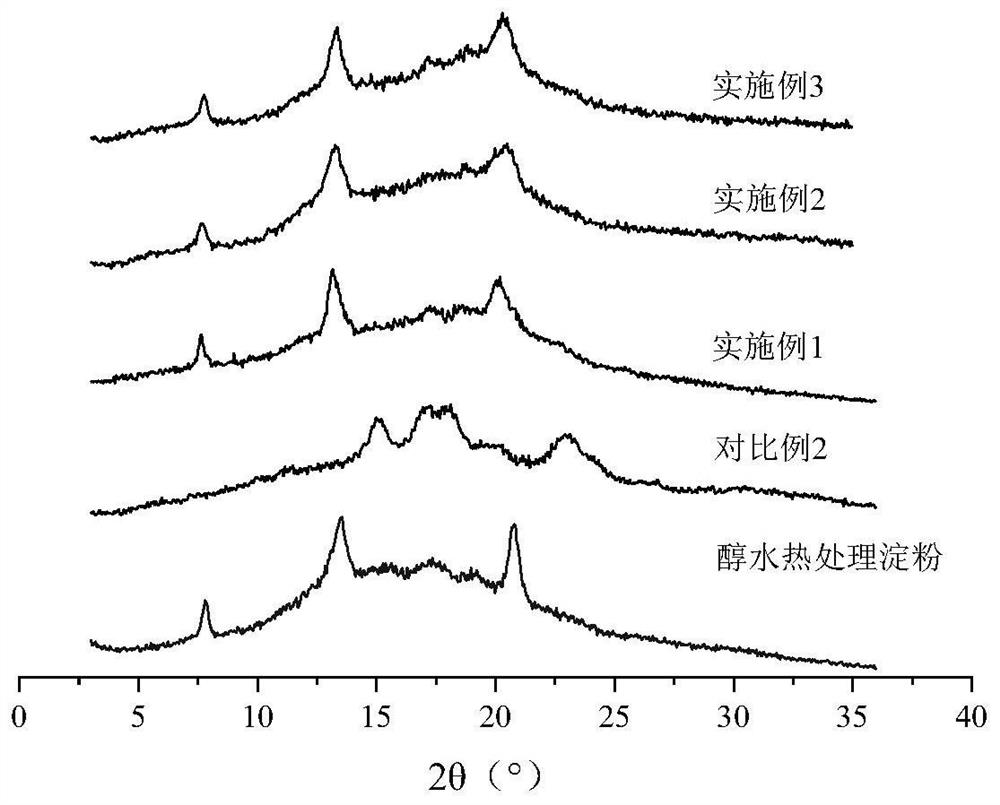

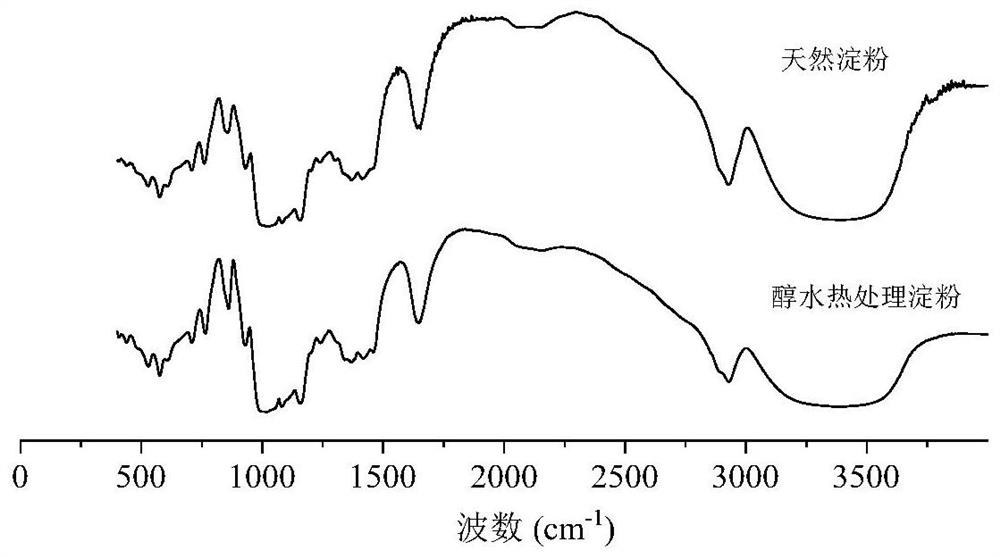

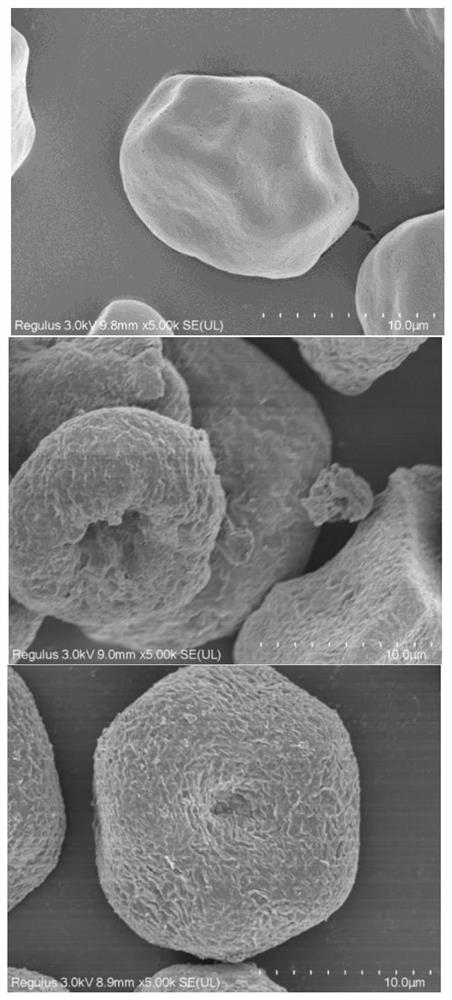

Embodiment 1

[0058] Prepare a 20% ethanol solution, weigh a certain amount of cornstarch and place it in a glass container, add the ethanol solution according to the ratio of starch: ethanol solution = 2:3, stir evenly, and send it to a microreactor for heating and heat preservation reaction. The parameters are: heat the reaction substance to 90°C, and keep it warm for 30 minutes to obtain mild alcohol hydrothermal treatment of corn starch. Transfer the product to a certain amount of ethanol solution to make the starch milk with a concentration of 20%. After mixing the two, Send it into a container for reaction, weigh 3% octenyl succinic anhydride and wait for the reaction. The reaction parameters are as follows: the reaction temperature is 45° C., the reaction pH value is 9, and the reaction time is 3 hours. After the reaction, wash with alcohol and filter with suction, put it in a microwave vacuum oven for drying, and dry it at 50°C for 24 hours, then take out the product and put it in a...

Embodiment 2

[0060] Prepare a 40% ethanol solution, weigh a certain amount of cornstarch and place it in a glass container, add the ethanol solution according to the ratio of starch: ethanol solution = 1:4, stir evenly, and send it to a microreactor for heating and heat preservation reaction. The parameters are: heat the reaction substance to 70°C and keep it warm for 30 minutes to obtain mild alcoholic hydrothermal treatment of cornstarch. Transfer the product to a certain amount of ethanol solution to make the starch milk with a concentration of 30%. After mixing the two, Send it into a container for reaction, weigh 13% octenyl succinic anhydride and wait for the reaction. The reaction parameters are as follows: the reaction temperature is 35° C., the reaction pH value is 8.0, and the reaction time is 5 hours. After the reaction, wash with alcohol and filter with suction, put it in a microwave vacuum drying oven for drying, and dry it at 50°C for 24 hours, then take out the product and p...

Embodiment 3

[0062] Prepare a 50% ethanol solution, weigh a certain amount of cornstarch and place it in a glass container, add the ethanol solution according to the ratio of starch: ethanol solution = 3:7, stir evenly, and send it into a microreactor for heating and heat preservation reaction. The parameters are: heat the reaction substance to 80°C and keep it warm for 30 minutes to obtain mild alcoholic hydrothermal treatment of corn starch. Transfer the product to a certain amount of ethanol solution to make the starch milk with a concentration of 35%. After mixing the two, Send it into a container for reaction, weigh 20% octenyl succinic anhydride and wait for reaction. The reaction parameters are as follows: the reaction temperature is 40° C., the reaction pH value is 8.3, and the reaction time is 4 hours. After the reaction, wash with alcohol and filter with suction, put it in a microwave vacuum drying oven for drying, and dry it at 50°C for 24 hours, then take out the product and pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com