Method for producing high-purity white phosphogypsum from phosphorite with high impurity content

A technology of impurity content and phosphogypsum, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of poor quality of phosphogypsum, affecting utilization, and high cost, so as to reduce reaction energy consumption, realize reuse, and improve Yield effect

Pending Publication Date: 2021-12-28

湖北省绿盛坤环保科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

) In the end, due to the impact of phosphate rock, the cost remained high. Finally, in the 1990s, all four sets of equipment built in the country were shut down. The use of phosphate rock is greatly limited, and the quality of phosphogypsum is getting worse and worse, which affects its utilization. Moreover, as the impurity content of phosphate rock increases, in order to ensure the washing of gypsum crystals, many domestic dihydrate processes have to reduce the concentration of P2O5 in the extraction tank to maintain production. However, it only eased a little production contradiction, and a large amount of phosphogypsum piled up like a mountain and could not be handled

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs.

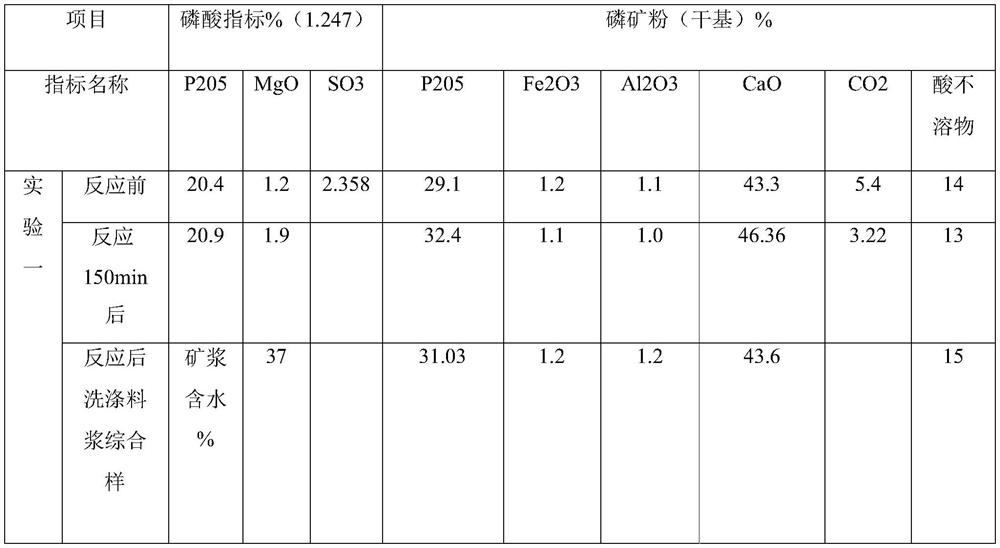

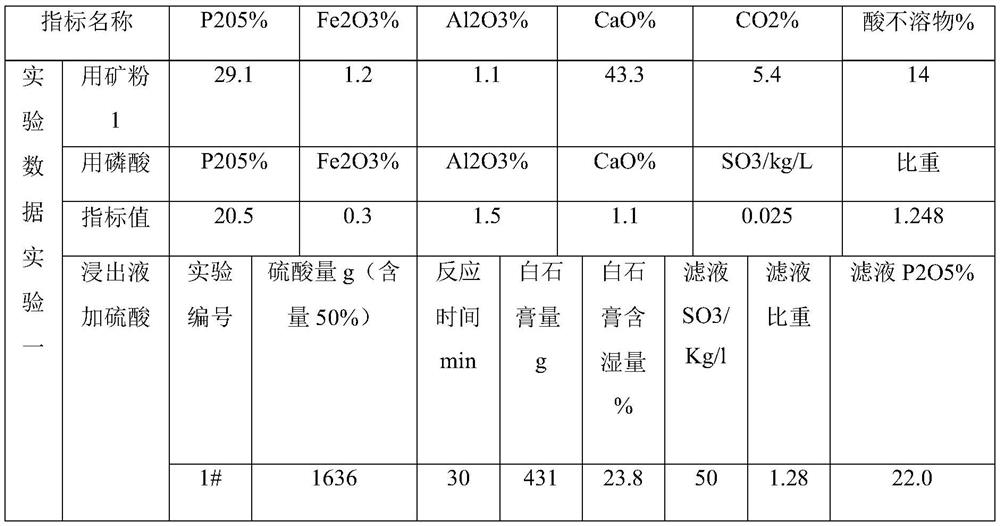

[0022] The present invention will be described in detail below in conjunction with specific experiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

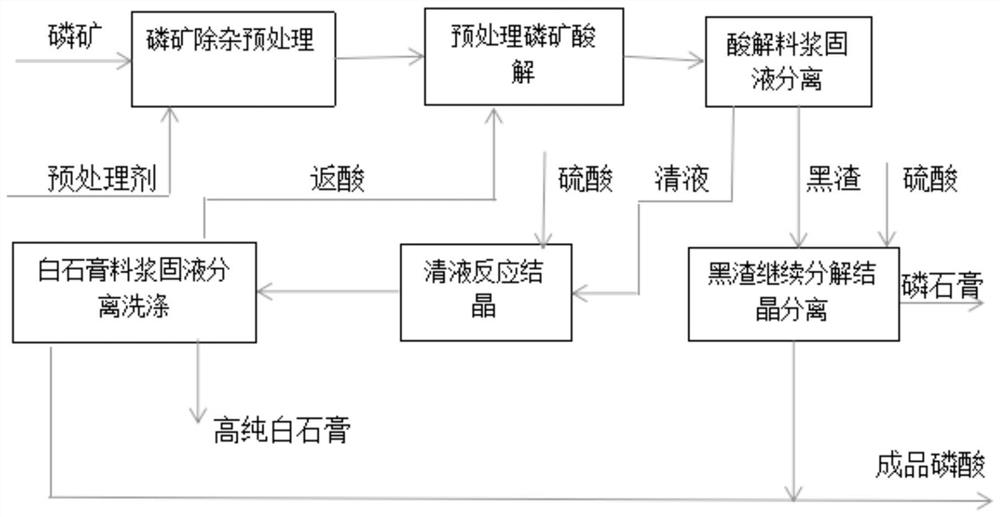

The invention discloses a method for producing high-purity white phosphogypsum from phosphorite with high impurity content. The method comprises but is not limited to the following steps: 1, pretreatment and impurity removal of phosphorite: adding high-impurity phosphorite (the phosphorite index is P2O5: 18-32%) into part of process hot water of a production system to prepare ore pulp with the temperature of 40-80 DEG C and the solid content of 20-70%, and then adding a phosphorite pretreatment agent to guarantee that the pH value is 2-5, and reacting for 1-5 hours to obtain the low-impurity high-activity phosphorite (P2O5: 18-32%). According to the method disclosed by the invention, the phosphorite is subjected to impurity pre-removal treatment before preparation, so that the reaction activity of the phosphorite and the saturation concentration of calcium ions in acid are effectively improved; therefore, the problem that the black slag generated in the production process of white phosphogypsum is difficult to treat is effectively solved, and the recycling of the black slag is realized; moreover, a high-concentration dihydrate crystallization process is realized, the reaction energy consumption can be effectively reduced, and the yield of phosphorite white gypsum is improved. Therefore, the acidolysis equipment is not excessively large in scale on the promise of ensuring the decomposition of the ore, and industrial production is realized.

Description

technical field [0001] The invention relates to the technical field of preparation of high-purity white phosphogypsum, in particular to a method for producing high-purity white phosphogypsum from phosphate rock with high impurity content. Background technique [0002] Waste slag produced by wet-process phosphoric acid production is a worldwide problem. The demand for phosphorus is essential, and the production of phosphogypsum is also inevitable, whether it is used for construction, or cement, or the production of sulfur The production of calcium carbonate by ammonium will put forward higher quality requirements for the purity of phosphogypsum. That is, only by improving its purity can it effectively broaden its scope of use and truly turn waste residue into treasure. [0003] However, with the development of human society and economy, the demand for phosphorus continues to increase, the mining volume of phosphate rock has increased sharply, the high-grade phosphate rock ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01F11/46

CPCC01F11/46

Inventor 许刚

Owner 湖北省绿盛坤环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com