Dechlorination method of microsphere solid and application thereof

A technology of microspheres and solids, applied in the direction of microsphere preparation, chemical instruments and methods, catalyst carriers, etc., can solve the problems of intensified corrosion of equipment, low yield of aromatics, low catalyst aromatization activity, etc., and achieve the goal of reducing severity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

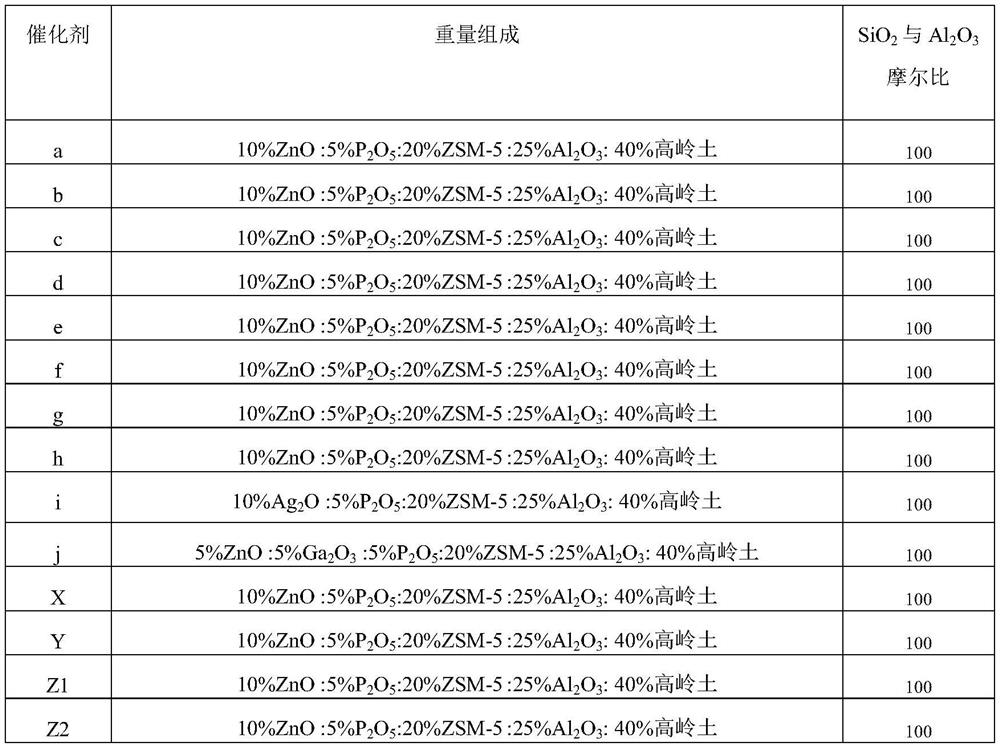

Embodiment 1

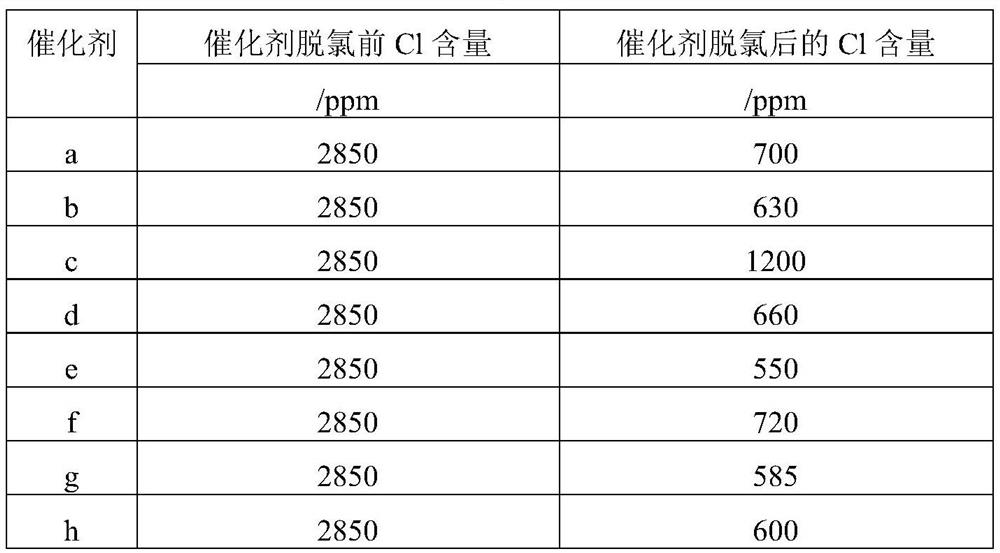

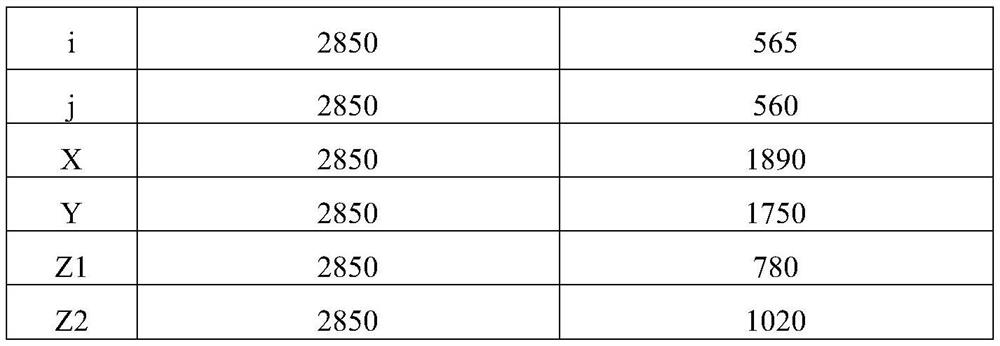

[0066] 80 grams of ZSM-5 molecular sieves (the molar ratio of silicon oxide to aluminum oxide=100), 476.2 grams of Al sol (21wt% Al 2 o 3 ), 158 grams of kaolin and 1500 grams of water are mixed uniformly to obtain a slurry, and the slurry is spray-dried to prepare a microsphere solid precursor SP1 with an average particle diameter of 72 microns, and the microsphere solid ZT1 is prepared by roasting at 550 ° C for 4 hours. It is 2850ppm.

[0067] Get 169 grams of microsphere solid ZT1 with 500 grams of buffer solution containing 9.5 grams of phosphoric acid and 9.5 grams of ammonium dihydrogen phosphate (pH=3.2) (the liquid-solid ratio of buffer solution and microsphere solid ZT1 is 3) at a temperature of 50 ° C, usually After being treated under pressure for 96 hours, it was washed with deionized water, dried at 120°C for 12 hours, and then calcined at 600°C for 3.5 hours to obtain the P-modified and dechlorinated microsphere solid DCL-1.

[0068] Take 90 grams of microsphe...

Embodiment 2

[0071] 80 grams of ZSM-5 molecular sieves (the molar ratio of silicon oxide to aluminum oxide=100), 476.2 grams of Al sol (21wt% Al 2 o 3 ), 158 grams of kaolin and 1500 grams of water are mixed uniformly to obtain a slurry, and the slurry is spray-dried to prepare a microsphere solid precursor SP1 with an average particle diameter of 72 microns, and the microsphere solid ZT1 is prepared by roasting at 550 ° C for 4 hours. It is 2850ppm.

[0072] Get 169 grams of microsphere solid ZT1 with 500 grams of aqueous solution containing 5 grams of phosphoric acid and 15.04 grams of ammonium dihydrogen phosphate (pH=3.8) (the liquid-solid ratio of the buffer solution and microsphere solid ZT1 is 3) at a temperature of 50 ° C under normal pressure After being treated at low temperature for 96 hours, it was washed with deionized water, dried at 120°C for 12 hours, and then calcined at 600°C for 3.5 hours to obtain the P-modified and dechlorinated microsphere solid DCL-2.

[0073] Take...

Embodiment 3

[0076] 80 grams of ZSM-5 molecular sieves (the molar ratio of silicon oxide to aluminum oxide=100), 476.2 grams of Al sol (21wt% Al2 o 3 ), 158 grams of kaolin and 1500 grams of water are mixed uniformly to obtain a slurry, and the slurry is spray-dried to prepare a microsphere solid precursor SP1 with an average particle diameter of 72 microns, and the microsphere solid ZT1 is prepared by roasting at 550 ° C for 4 hours. It is 2850ppm.

[0077] Get 169 grams of microsphere solid ZT1 with 500 grams of aqueous solution containing 1.5 grams of phosphoric acid and 18.0 grams of ammonium dihydrogen phosphate (pH=5.5) (the liquid-solid ratio of the buffer solution and microsphere solid ZT1 is 3) at a temperature of 50 ° C under normal pressure After being treated for 96 hours, it was washed with deionized water, dried at 120°C for 12 hours, and then calcined at 600°C for 3.5 hours to obtain the P-modified and dechlorinated microsphere solid DCL-3.

[0078] Take 90 grams of carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com