Catalyst for preparing aromatic hydrocarbons from methanol and application thereof

A catalyst, methanol technology, applied in molecular sieve catalysts, physical/chemical process catalysts, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of low aromatization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Mix 40 grams of zinc nitrate hexahydrate, 8.4 grams of copper nitrate trihydrate, 0.006 grams of calcium bicarbonate and 210 grams of water, and stir evenly to obtain solution I. Add 120 grams of hydrogen-type ZSM-5 molecular sieve into solution I, mix well, heat and evaporate excess water, and roast at 550°C for 4 hours to obtain a modified molecular sieve. Mix 11.3 grams of diammonium hydrogen phosphate and 90 grams of water, and stir to obtain solution II. After molding the above-mentioned modified molecular sieve, add it into solution II, mix evenly, heat and evaporate excess water, and then roast it at 550°C for 4 hours to obtain a methanol-to-aromatics catalyst, which is designated as MTA-1.

[0043] Catalyst evaluation was carried out on a methanol to aromatics unit. The feed is pure methanol, the reaction temperature is 480°C, the reaction pressure is 0.01MPa, and the methanol weight space velocity is 1h-1 .

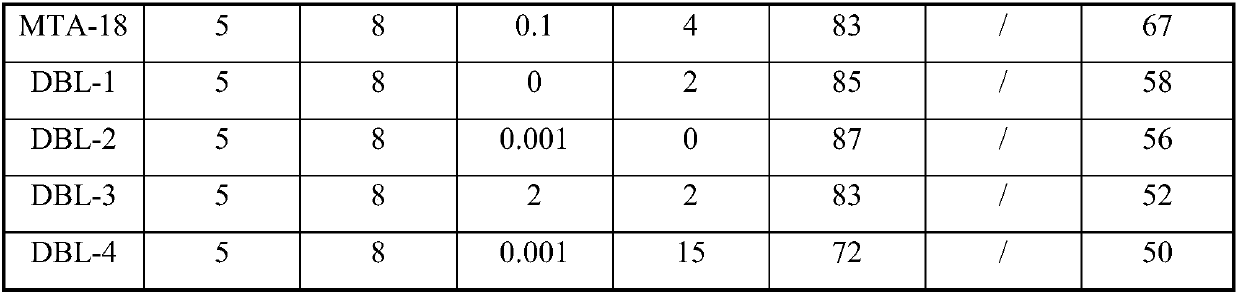

[0044] The composition and evaluation results of t...

Embodiment 2

[0046] Mix 40 grams of zinc nitrate hexahydrate, 8.4 grams of copper nitrate trihydrate, 0.056 grams of calcium bicarbonate and 210 grams of water, and stir evenly to obtain solution I. Add 120 grams of hydrogen-type ZSM-5 molecular sieve into solution I, mix well, heat and evaporate excess water, and roast at 550°C for 4 hours to obtain a modified molecular sieve. Mix 11.3 grams of diammonium hydrogen phosphate and 90 grams of water, and stir to obtain solution II. After molding the above-mentioned modified molecular sieve, add it into solution II, mix evenly, heat and evaporate excess water, and then roast it at 550°C for 4 hours to obtain a methanol-to-aromatics catalyst, which is designated as MTA-2.

[0047] Catalyst evaluation is the same as in Example 1.

[0048] The composition and evaluation results of the catalysts are listed in Table 1.

Embodiment 3

[0050] Mix 40 grams of zinc nitrate hexahydrate, 8.4 grams of copper nitrate trihydrate, 0.56 grams of calcium bicarbonate and 210 grams of water, and stir evenly to obtain solution I. Add 120 grams of hydrogen-type ZSM-5 molecular sieve into solution I, mix well, heat and evaporate excess water, and roast at 550°C for 4 hours to obtain a modified molecular sieve. Mix 11.3 grams of diammonium hydrogen phosphate and 90 grams of water, and stir to obtain solution II. After molding the above-mentioned modified molecular sieve, add it to solution II, mix evenly, heat and evaporate excess water, and then roast it at 550°C for 4 hours to obtain a methanol-to-aromatics catalyst, which is designated as MTA-3.

[0051] Catalyst evaluation is the same as in Example 1.

[0052] The composition and evaluation results of the catalysts are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com