Automatic point taking device of resiliometer

A technology of automatic point picking and rebound tester, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of potential safety hazards, aggravated safety hazards, and application of reaction force, etc., so as to save working space, optimize structure, and reduce equipment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

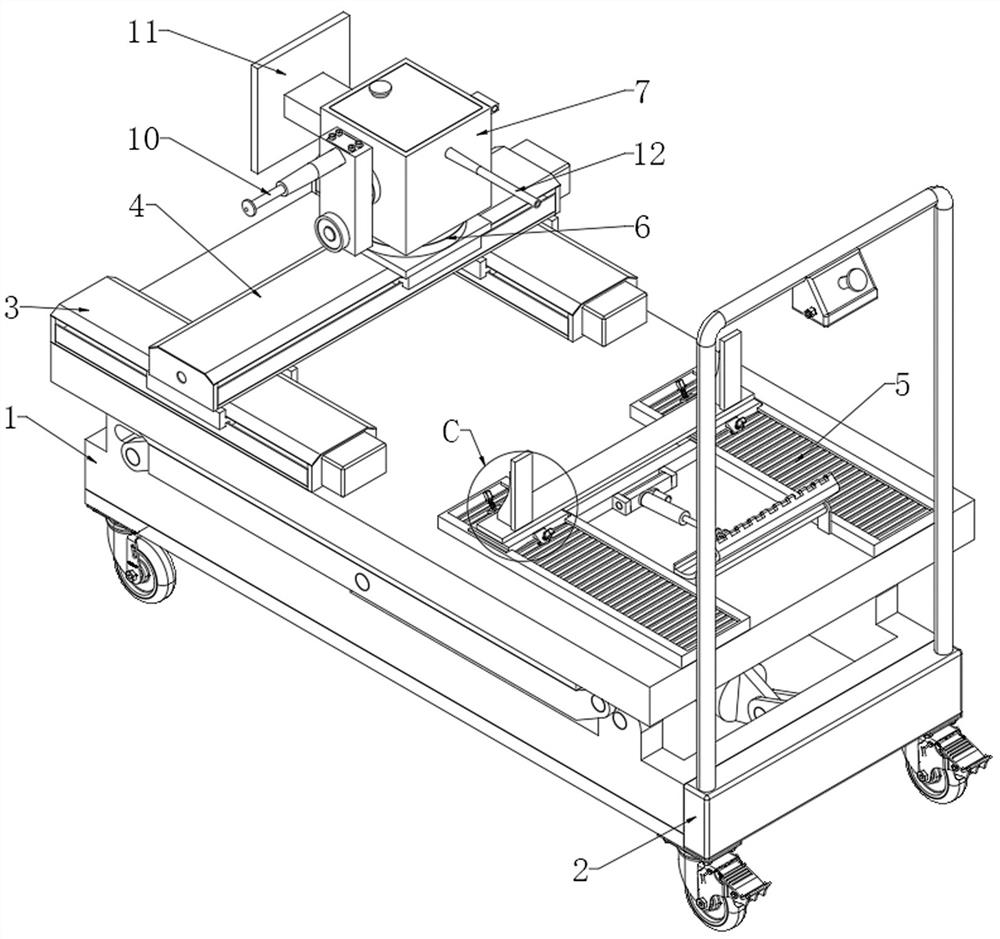

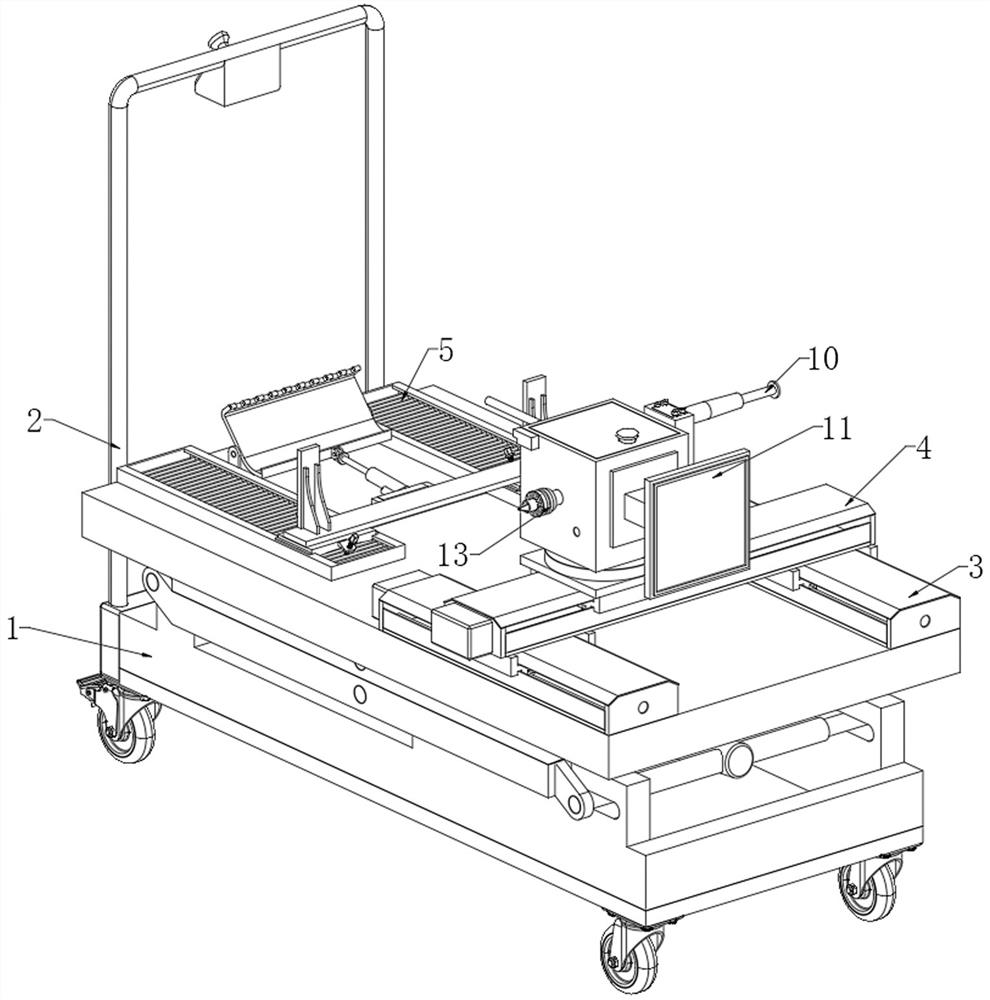

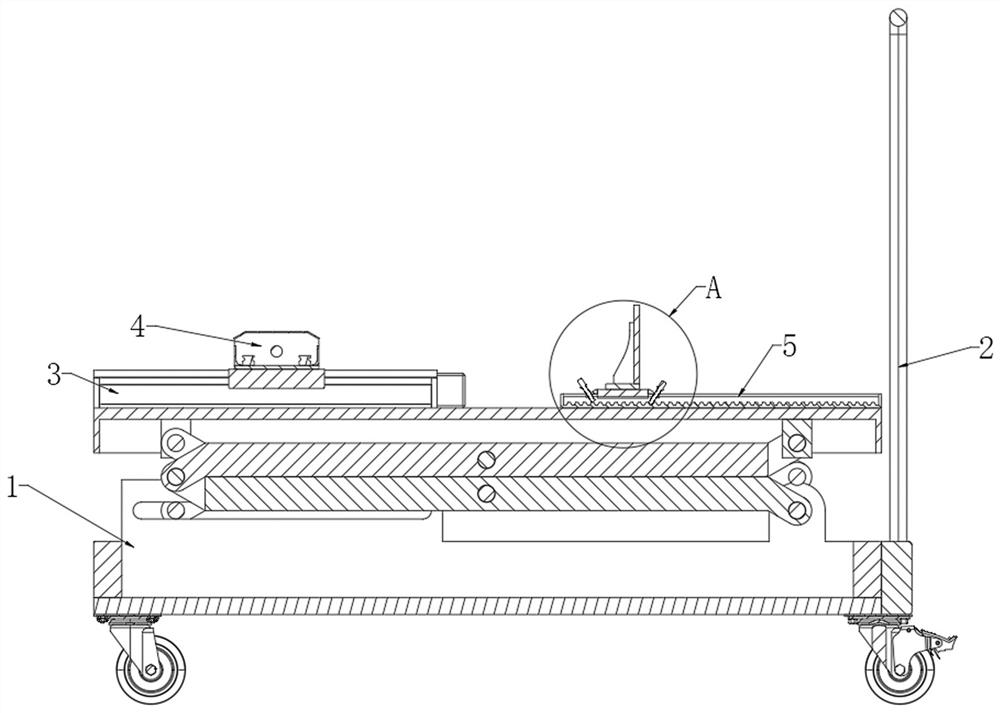

[0038] see Figure 1-10, an automatic point-taking device for a rebound hammer, comprising a lifting trolley 1, a push rod 2 is arranged on one side of the lifting trolley 1, and a longitudinal electric slide rail 3 and a crossbeam clamping device 5 are arranged on the top of the lifting trolley 1, The top of the longitudinal electric slide rail 3 is provided with a horizontal electric slide rail 4, and the top of the horizontal electric slide rail 4 is provided with an electric turntable 6, and the top of the electric turntable 6 is rotatably connected with a turntable 7, and the four sides of the turntable 7 are respectively provided with springback Instrument 10, square stamp 11, catheter 12, drill bit clamp 13, distance measuring camera 21.

[0039] refer to Figure 5 , the top of the turntable 7 is fixedly connected with a drill clamp 13, one side of the drill clamp 13 is provided with a peristaltic pump 14, the input end of the peristaltic pump 14 communicates with the ...

Embodiment 2

[0047] Please refer to Figure 10 , this embodiment is compared with embodiment 1, the difference is that: the rebound instrument 10 and the square stamp 11 are arranged on the outer wall of the turntable 7 oppositely, and the bevel gear three 906, the gear set two 907, and the one-way bearing 903 , transmission shaft 904, correspondingly changing its transmission position.

[0048] Compared with the rebound hammer 10 and the square seal 11 being adjacently arranged on the outer wall of the turntable 7, the rebound hammer 10 and the square seal 11 are arranged opposite to each other, so that the size of the square seal 11 can be unlimited, thereby reducing the number of imprints and improving the purpose of work efficiency.

[0049] see Figure 8 Compared with Embodiment 1, this embodiment differs in that: the transmission end of the driving device 2 or the driving device 2 6 is in transmission connection with the transmission connection head 2 405 of the steering transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com