Axial bearing structure and motor

An axial bearing and bearing technology, applied in the field of compressors, can solve problems such as poor cooling effect, and achieve the effects of improving heat dissipation capacity, improving cooling effect, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

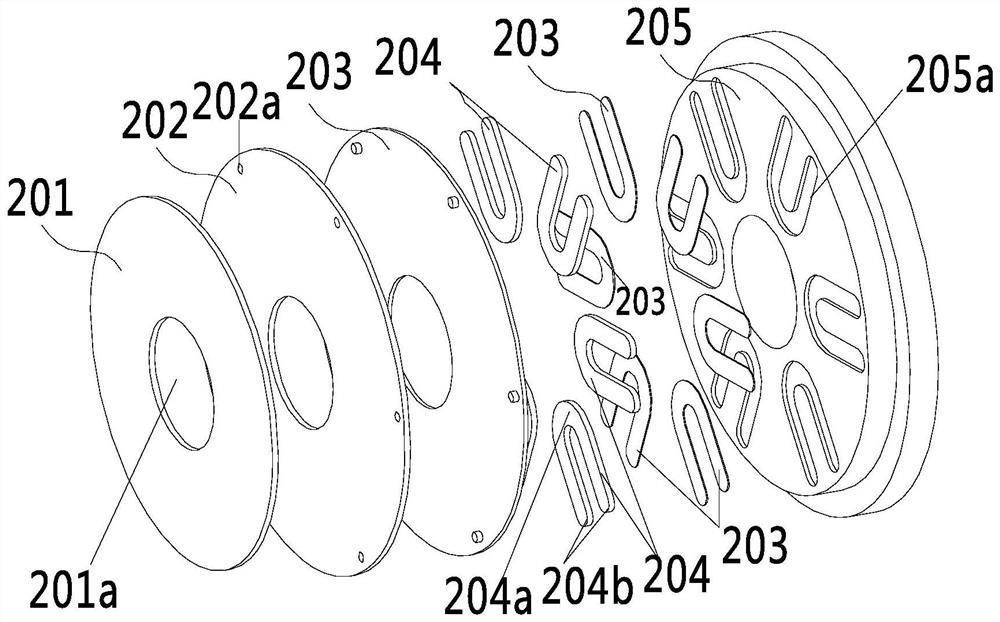

[0043] Such as Figure 3-6 , the present invention provides an axial bearing structure, which includes:

[0044] Bearing 201, bearing base 202, end cover 205 and heat conducting member 204, the bearing 201 (preferably an air bearing) is connected to the bearing base 202, the bearing 201 includes a first shaft hole 201a, and the heat conducting member 204 sandwiches Between the bearing base 202 and the end cover 205, the thermal conductivity of the heat conducting member 204 is greater than the thermal conductivity of the bearing base 202;

[0045] The heat conduction element 204 includes a first end 204a and a second end 204b, the first end 204a and the second end 204b of the heat conduction element 204 have a physical extension structure, and the first end 204a is arranged at Relative to the position of the second end 204b close to the first shaft hole 201a or at a position opposite to the outer circle of the first shaft hole 201a in the axial direction, the second end 204b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com