Composite filler taking fine coal gasification slag as raw material, preparation method and application thereof

A composite filler, coal gasification technology, applied in the field of plastic thermal insulation filler, to achieve the effect of improving strength, fine particle size and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

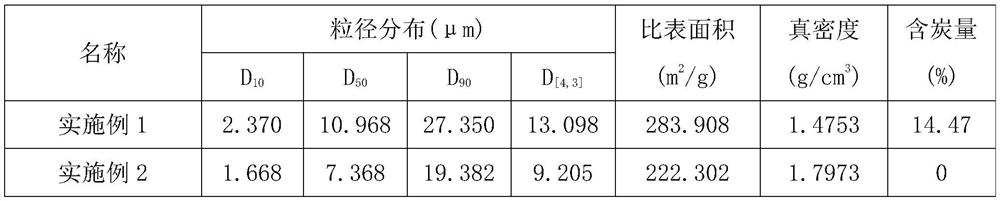

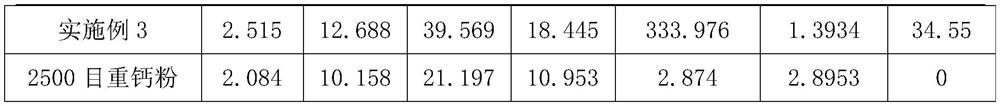

Embodiment 1

[0022] The method of a porous carbon / mesoporous silica composite filler prepared from coal gasification fine slag as raw material provided in this embodiment is as follows:

[0023] (1) Take 100 g of coal gasification fine slag, add water and dilute it into a coal gasification fine slag slurry with a solid matter fraction of 15 wt %;

[0024] (2) Fully stir the coal gasification fine slag slurry at room temperature with a high-speed dispersion mixer, the stirring speed is 1600r / min, and the stirring time is 40min; after stirring, it is introduced into a screening device, and the large particle solid component is separated by passing through a 200-mesh sieve. Collect the separated slurry under the sieve to obtain the composite slurry;

[0025] (3) get 130ml of concentrated hydrochloric acid of 36wt% and mix with composite slurry, adjust the total volume of mixed slurry by adding water, make the mass fraction of slurry acid be 16wt%, solid matter mass fraction be 20wt%, stir 5h ...

Embodiment 2

[0030] The method of a porous carbon / mesoporous silica composite filler prepared from coal gasification fine slag as raw material provided in this embodiment is as follows:

[0031] (1) Take 100 g of coal gasification fine slag, add water and dilute it into a coal gasification fine slag slurry with a solid matter fraction of 20 wt %;

[0032] (2) Fully stir the coal gasification fine slag slurry at room temperature with a high-speed dispersion mixer, the stirring speed is 1800r / min, and the stirring time is 60min; after stirring, it is introduced into a screening device, and the large particle solid component is separated by passing through a 200-mesh sieve. Collect the separated slurry under the sieve to obtain the composite slurry;

[0033] (3) 130ml of concentrated hydrochloric acid of 36wt% is mixed with the composite slurry, and the total volume of the mixed slurry is adjusted by adding water, so that the mass fraction of the slurry acid is 20wt%, and the solid mass fract...

Embodiment 3

[0038] The method of a porous carbon / mesoporous silica composite filler prepared from coal gasification fine slag as raw material provided in this embodiment is as follows:

[0039] (1) Take 100 g of coal gasification fine slag, add water and dilute it into a coal gasification fine slag slurry with a solid matter fraction of 25 wt %;

[0040](2) Fully stir the coal gasification fine slag slurry at room temperature with a high-speed dispersion mixer, the stirring speed is 2000r / min, and the stirring time is 80min; after stirring, it is introduced into a screening device, and the large particle solid component is separated by passing through a 200-mesh sieve. Collect the separated slurry under the sieve to obtain the composite slurry;

[0041] (3) Get 130ml of 36wt% concentrated hydrochloric acid and mix it with the composite slurry, adjust the total volume of the mixed slurry by adding water, so that the mass fraction of the slurry acid is 22wt%, and the solid mass fraction is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com