Cutting device for thermal insulation integrated prefabricated wall and operation method

A cutting device and prefabricated wall technology, applied in the direction of work accessories, manufacturing tools, stone processing tools, etc., can solve the problems affecting the beauty and strength of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

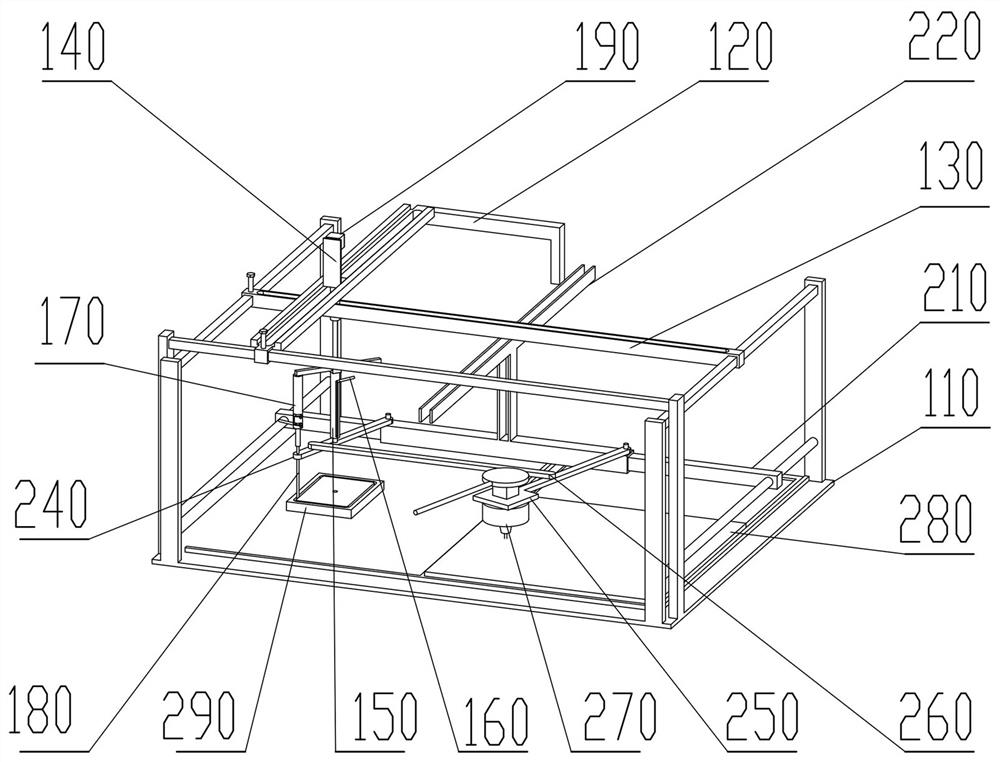

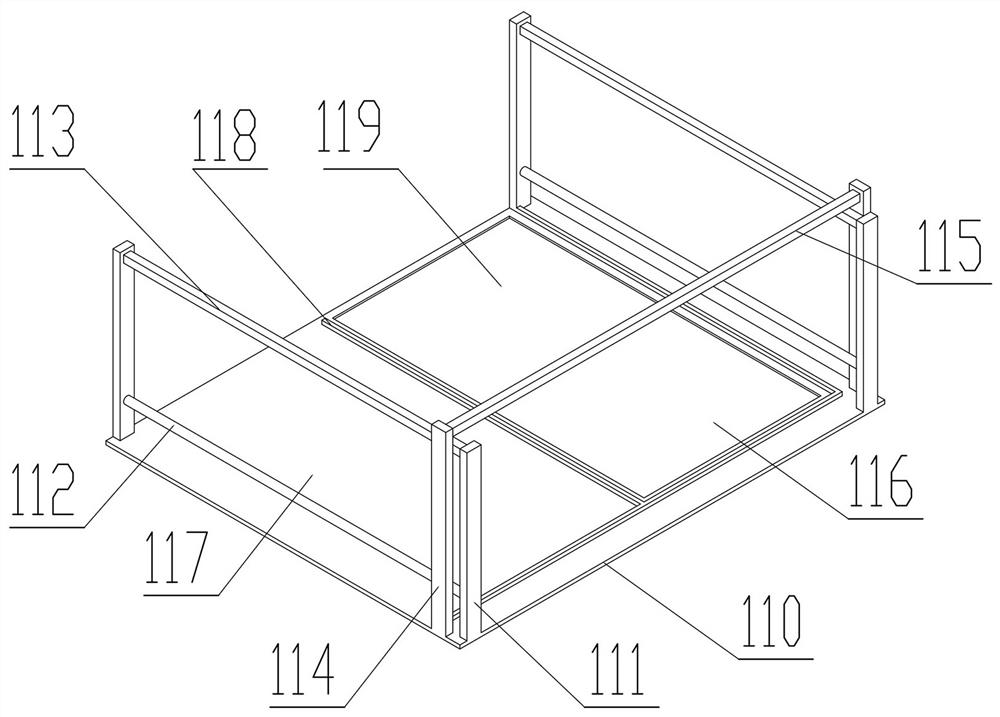

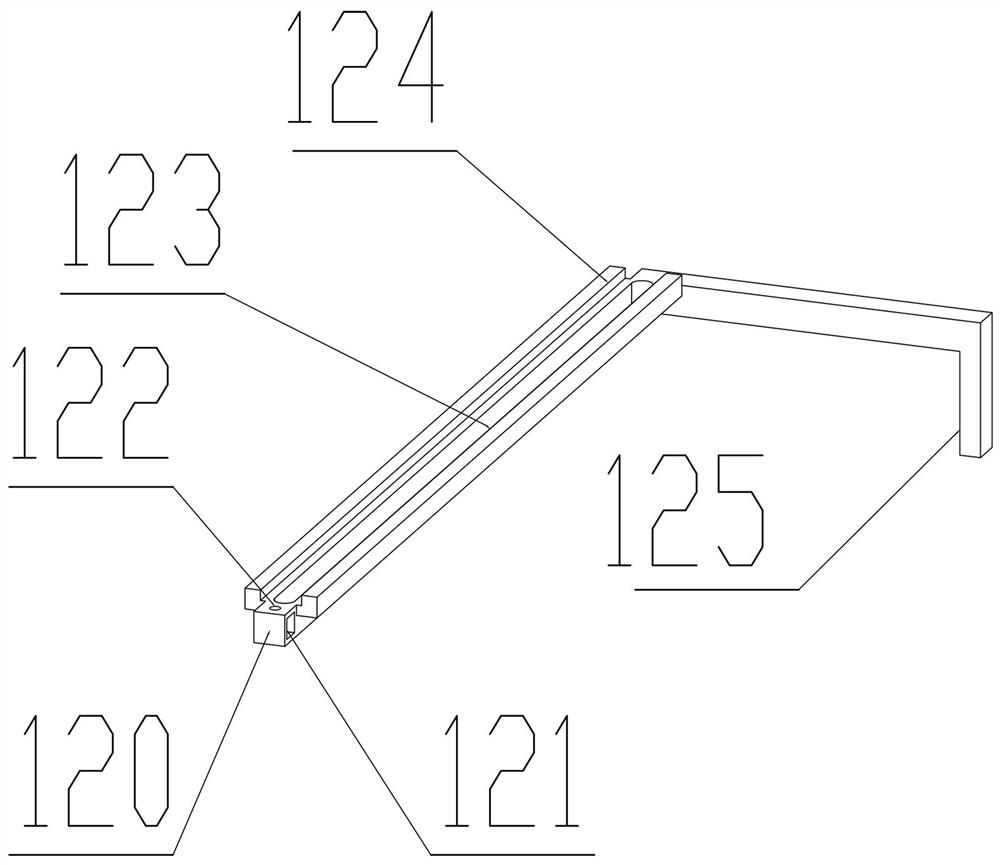

[0027] A cutting device for thermal insulation integrated prefabricated walls, including a base 110, a No. 1 sliding seat 120, a No. 2 sliding seat 130, a motor base 140, a main shaft 150, a positioning pin 160, a follower rod 170, a cam rod 180, and a moving rod 210 , mobile frame 220, left connecting rod 240, right connecting rod 250, middle rod 260, milling head 270, template 290, the upper left side of the base 110 has two No. 1 columns 111 symmetrically arranged, and two No. 1 columns 111 The lower part is respectively connected with the round slide bar 112 of two No. 1 columns 111, the top of the two No. 1 columns 111 has the No. 1 slide bar 113 connected with the two No. 1 columns 111, and the right side of the base 110 has the No. 1 column 111, The No. 1 column 111, the round slider 112, the No. 1 slide bar 113 that round slide bar 112, No. 1 slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com