Production process and application of hydrogenation reactor high-voltage sheathed thermocouple protection device

A technology of armored thermocouples and hydrogenation reactors, applied in chemical instruments and methods, refining to remove heteroatoms, chemical/physical processes, etc., can solve the urgent need for armored thermocouple protection, unstable temperature detection, and catalyst failure Discharge and other issues to achieve the effect of improving application assembly efficiency, improving stability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below we combine the Figure 1-9 And the present invention is described in further detail, the following examples are used to illustrate the present invention, but not limit the scope of the present invention.

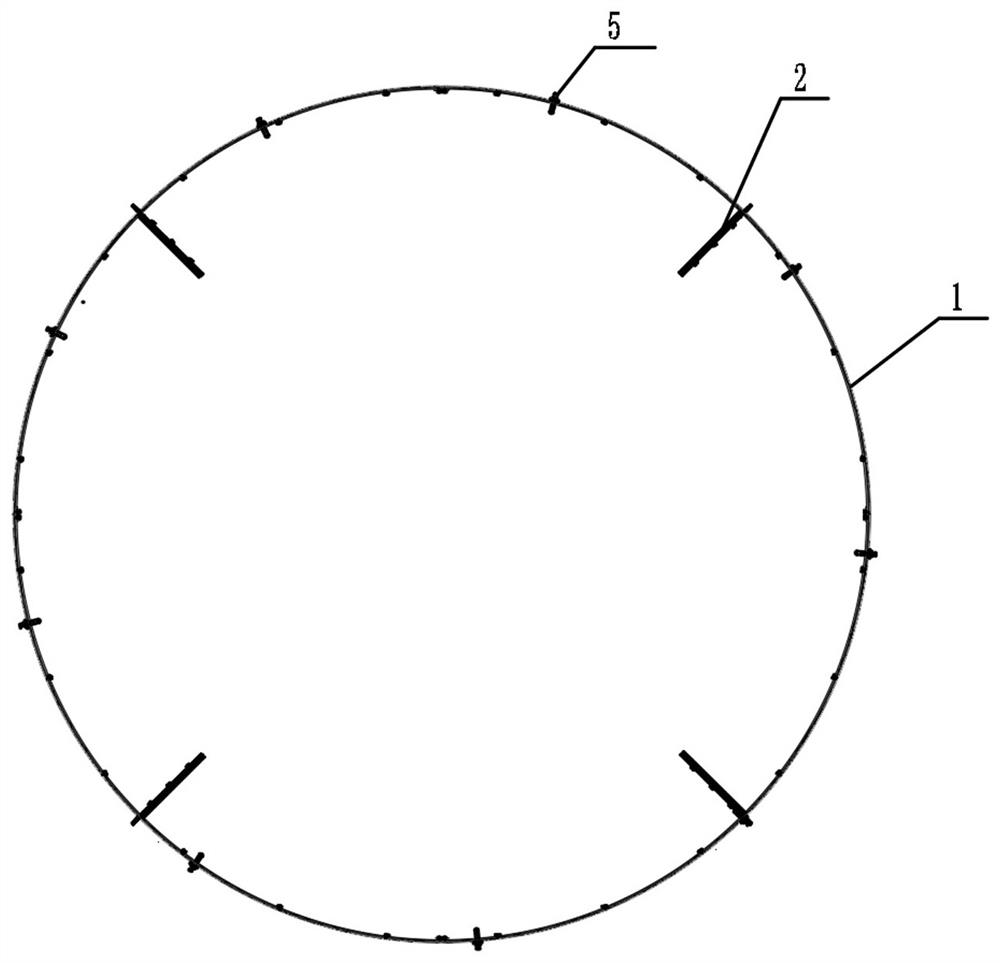

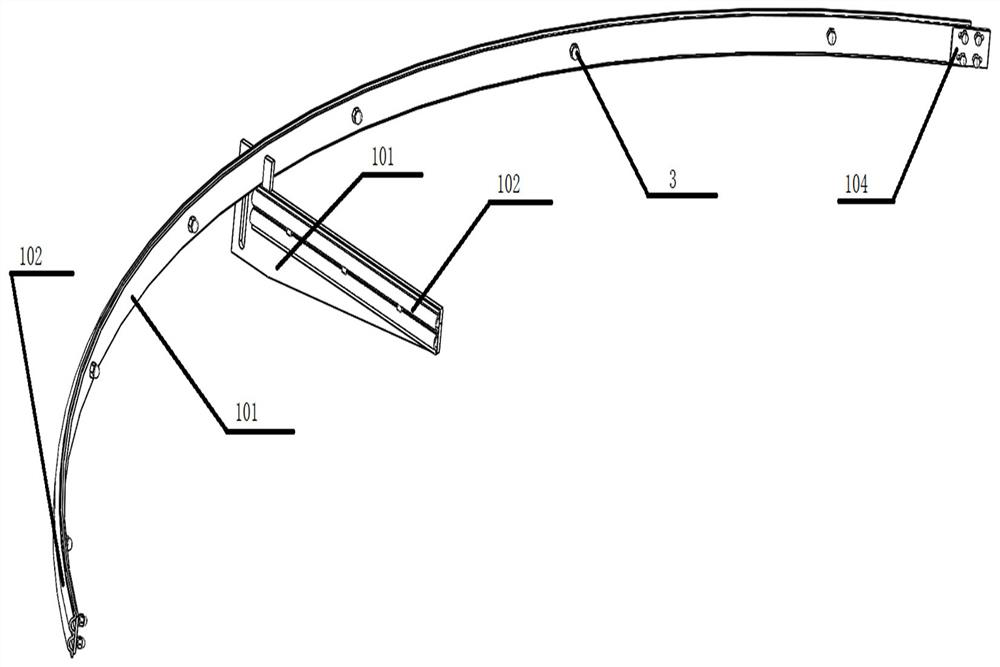

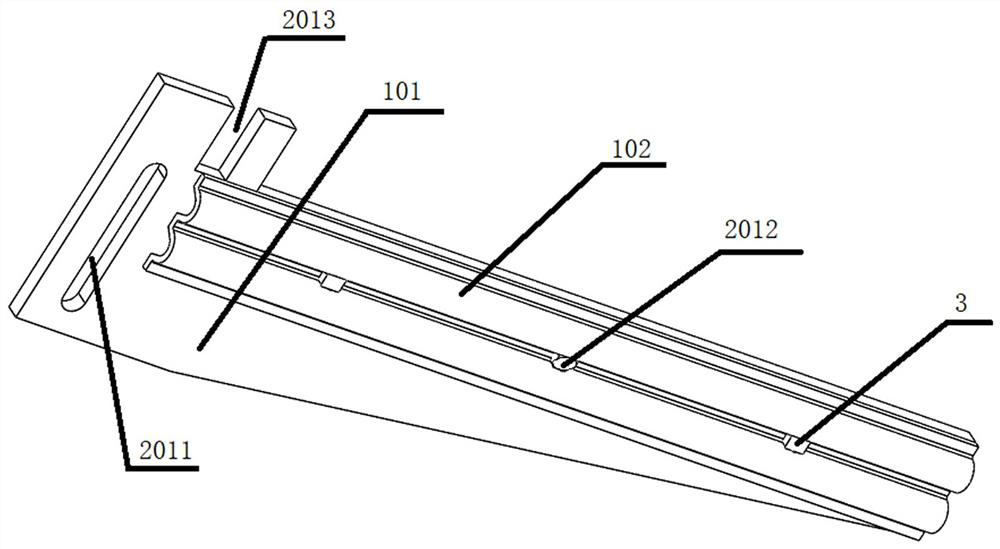

[0038] See attached Figure 1-9 , a production process of a high-voltage armored thermocouple protection device for a hydrogenation reactor in the present invention, when manufacturing, firstly, the protection mechanism 1 and the support mechanism for installing the protection mechanism must be designed according to the shape and structure of the inner wall of the hydrogenation reactor 2; taking the shape of the inner wall of a circular hydrogenation reactor as an example, the protective mechanism 1 and the support mechanism 2 on which the protective mechanism is installed are designed to be arc-shaped corresponding to the inner wall during manufacture; and the protective mechanism 1 and the support mechanism 2 Each includes a carrier substrate 101 and a protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com