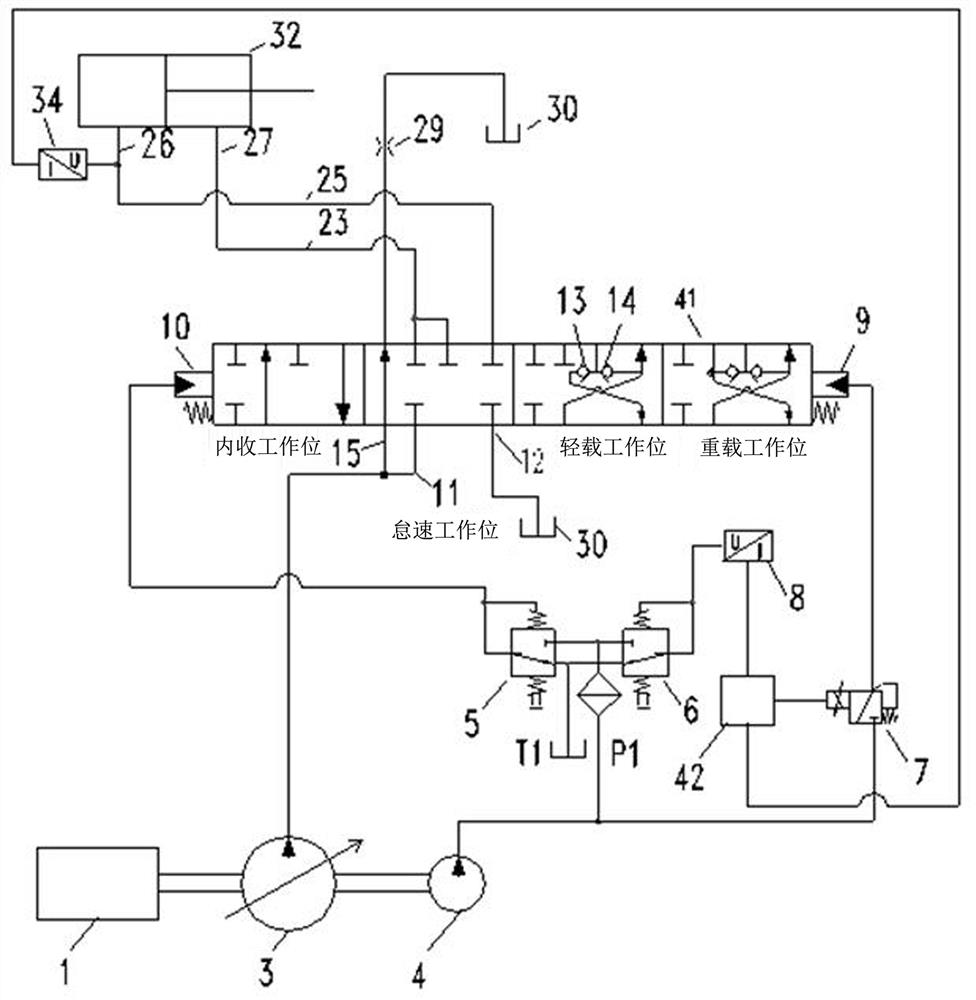

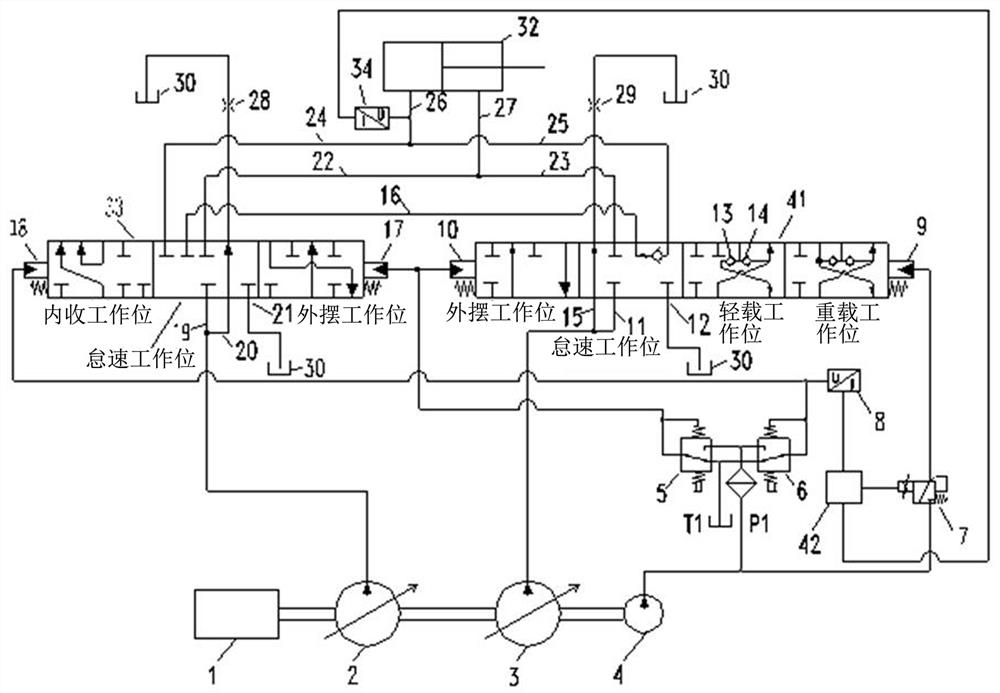

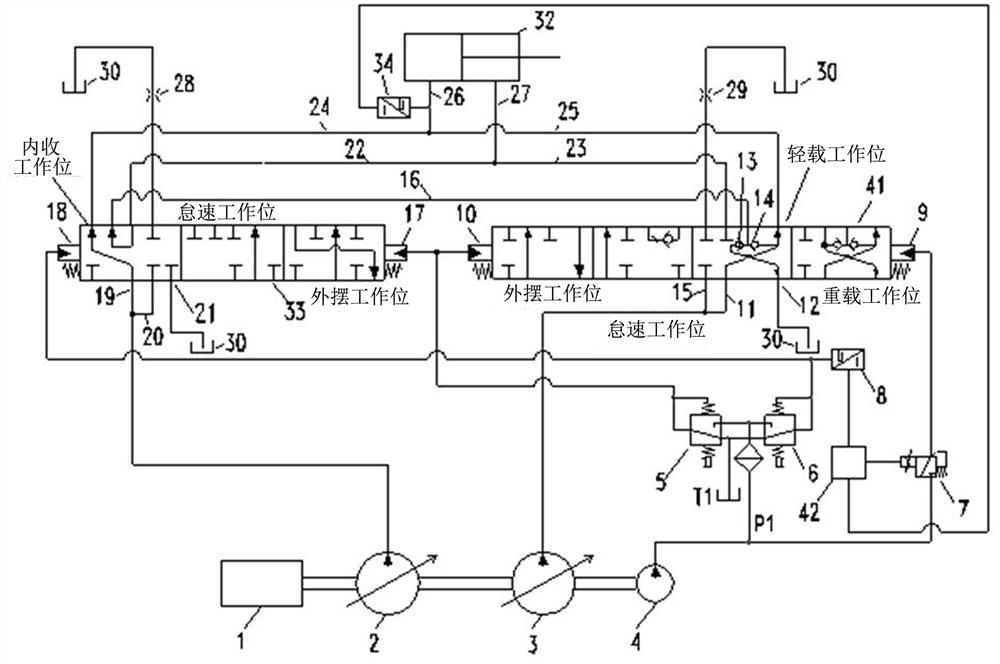

A hydraulic system and control method for electric proportional control multi-position valve

A hydraulic system and working position technology, applied in the field of hydraulic pressure, can solve the problems of high energy consumption loss, large oil return back pressure, and low work efficiency of the machine, so as to increase the oil return area, reduce the oil return back pressure, and increase the The effect of oil flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

[0047] In construction machinery, when the thrust direction of the hydraulic cylinder is opposite to the direction of the load (in most cases), the load is called a resistance load; As a result, the load on the hydraulic cylinder is in the same direction as the thrust of the hydraulic cylinder, and the load is called a tensile load at this time. Under the condition of tension load, the cavity on the oil supply side of the cylinder is very easy to cause the hydraulic components to suck due to insufficient flow. Therefore, under the condition of tension load, it is usually necessary to artificially set a high oil return back pressure to prevent the components Cavitation damage occurs. High oil return back pressure will cause the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com