Hydraulic system of horizontal buffer cylinder of forging and pressing operating machine

A technology of horizontal buffering and hydraulic system, which is applied to the driving device, mechanical equipment, fluid pressure actuating device, etc. of the forging press. It can achieve the effect of simple and fast switching action, reduced structural complexity and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

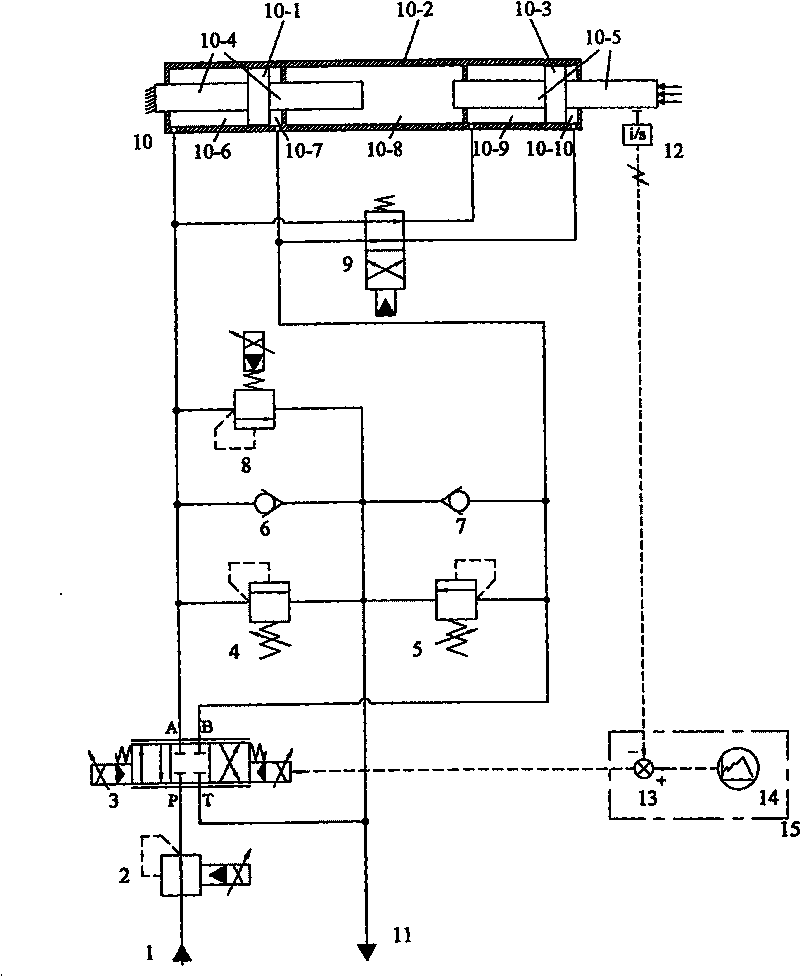

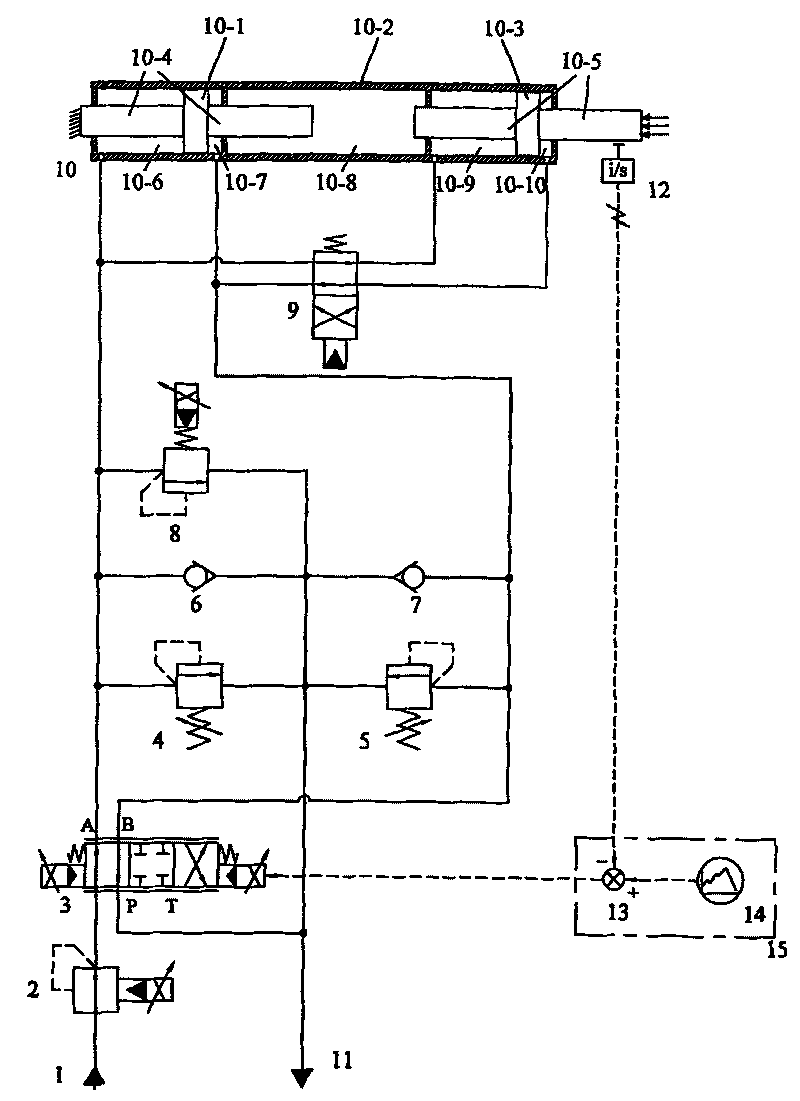

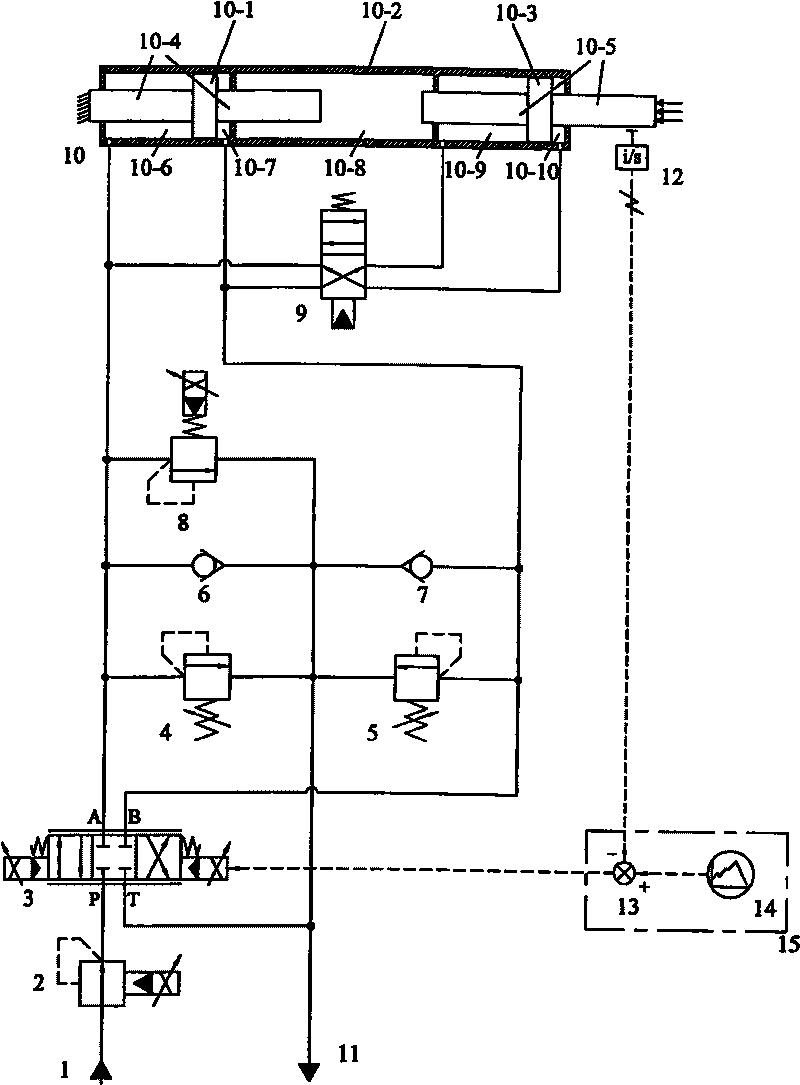

[0021] refer to figure 1 As shown, in the horizontal buffer cylinder hydraulic system of the forging manipulator disclosed in the present invention, the inlet and outlet of the proportional pressure reducing valve 2 are respectively connected with the oil supply port 1 of the oil source and the oil inlet P of the proportional directional valve 3, and the proportional directional valve 3 Port A is respectively connected to the inlet of the first safety valve 4, the outlet of the first one-way valve 6, the inlet of the proportional overflow valve 8, and the outer chamber 10-6 of the first chamber of the buffer cylinder, and the port B of the proportional directional valve 3 is connected to the second safety valve respectively. The inlet of the valve 5, the outlet of the second one-way valve 7, and the inner chamber 10-7 of the first chamber of the buffer cylinder are connected. The outlet of the second overflow valve 5, the inlet of the first one-way valve 6, the inlet of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com