Cotton yarn space dyeing equipment facilitating dye recovery

A cotton yarn and dye technology, applied in the field of textile related equipment, can solve the problems of increased cost, easy agglomeration of dyes, uneven spray amount, etc., to meet the needs of use, reduce the cost of use, and improve the efficiency of stage dyeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

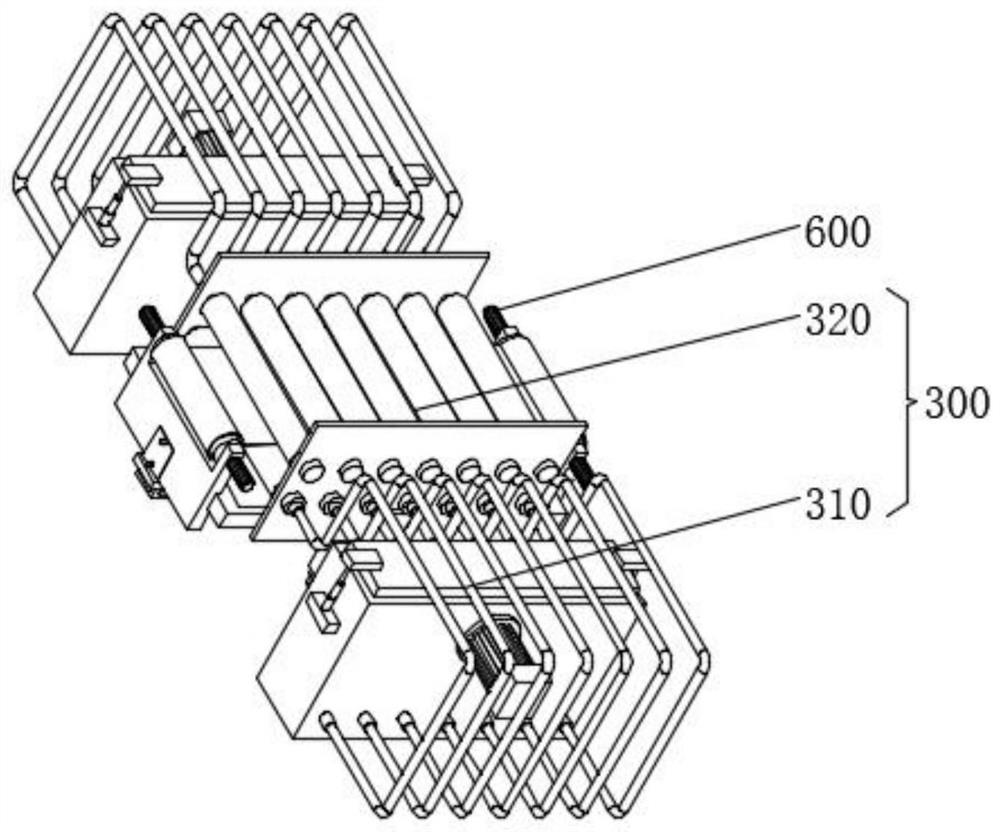

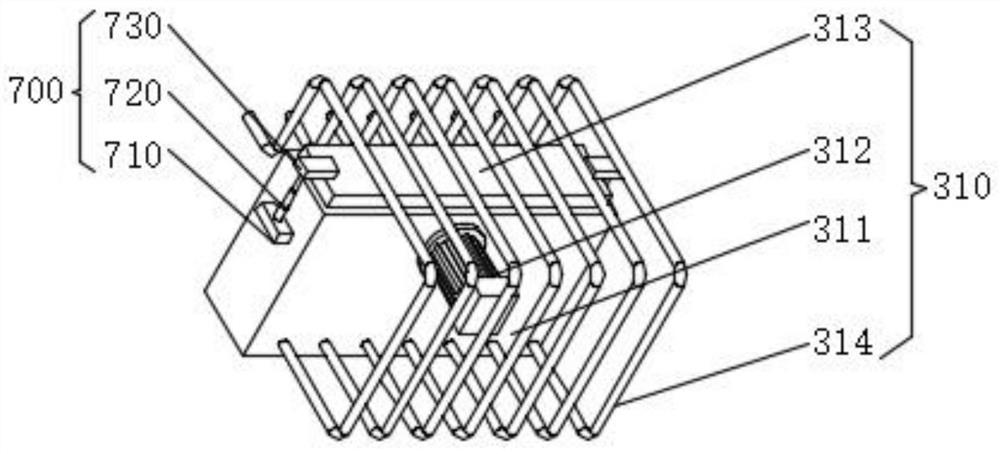

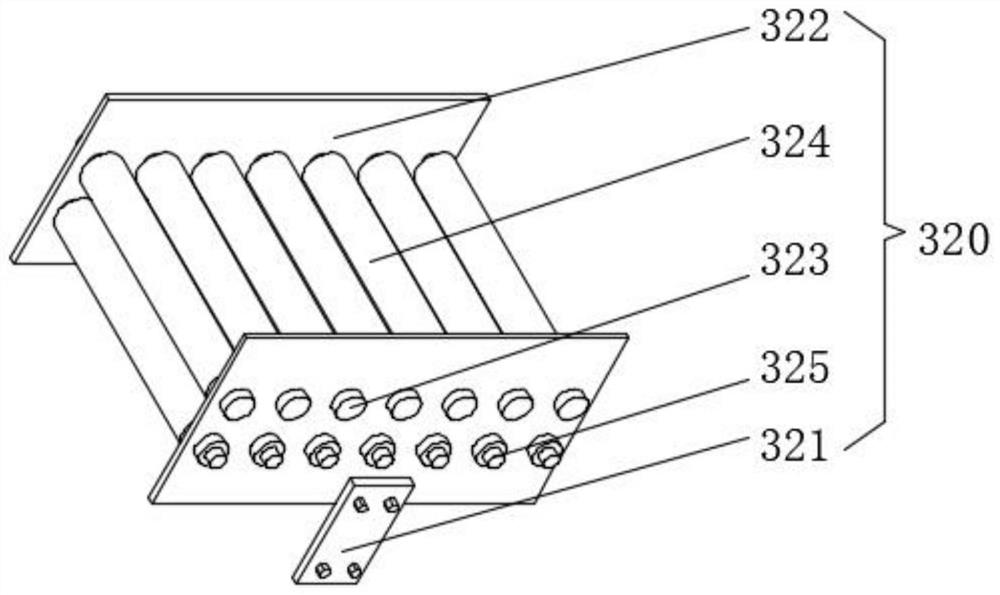

[0049] see Figure 1-8 As shown, the present invention is a cotton yarn segment dyeing device that is convenient for dye recovery, including an installation mechanism 100, a segment dyeing mechanism 300, a material receiving mechanism 400 and a material cleaning mechanism 500, and the central position on both sides of the installation mechanism 100 is connected with a segment dyeing mechanism 300 , and the section dyeing assembly 320 and the feeding assembly 310 included in the section dyeing mechanism 300 are respectively arranged at the inner and outer ends of both sides of the installation mechanism 100;

[0050] Both sides of the installation mechanism 100 are movably connected with a rewinding and unwinding mechanism 600 through the movable mechanism 200, and the inner lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com