Stirring device for cement-based composite shielding material

A composite shielding and stirring device technology, which is applied in the field of cement-based materials, can solve the problems of electromagnetic shielding materials that cannot be uniformly mixed, electromagnetic shielding materials fall wantonly, etc., and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

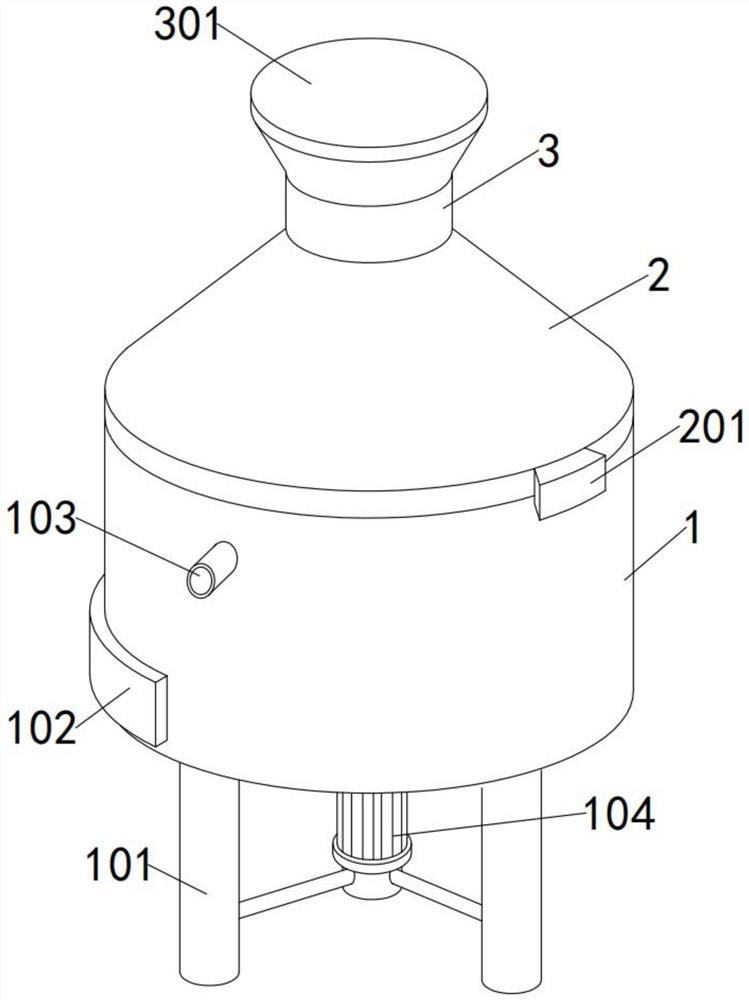

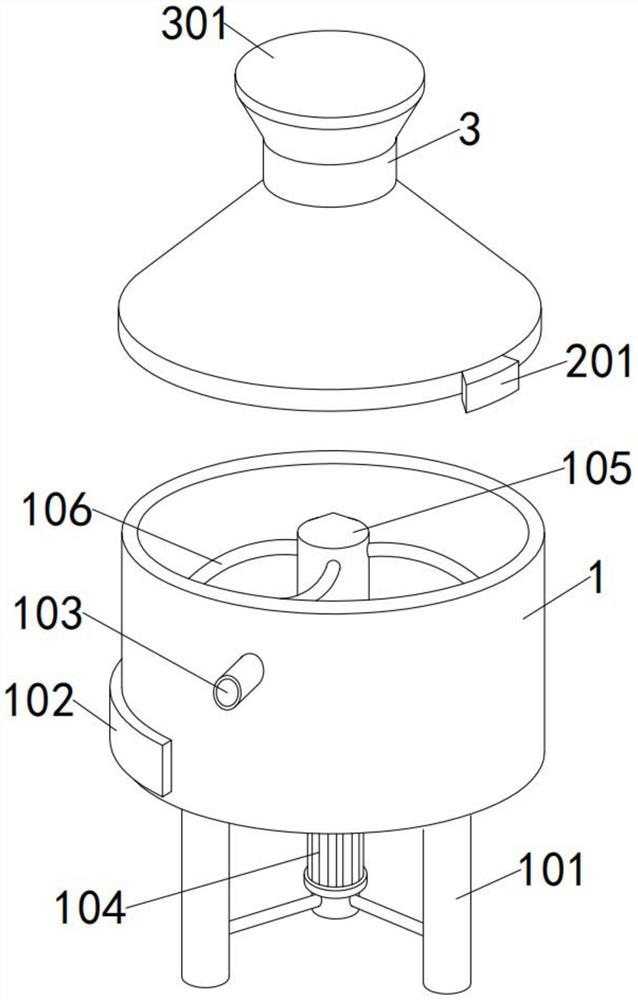

[0039] see Figure 1-6, in the embodiment of the present invention, a top cover 2 is installed above the mixing bucket 1, a leg 101 is fixedly connected to the bottom of the mixing bucket 1, a discharge plate 102 is movably connected to the bottom of the side of the mixing bucket 1, and an inlet is embedded in the side of the mixing bucket 1. The water pipe 103 is connected to the rotating shaft 105 inside the mixing tank 1, and the stirring rod 106 is fixed at an equal angle around the rotating shaft 105. The stirring motor 104 is fixedly connected to the leg 101, and the power output end of the stirring motor 104 passes through the bottom of the rotating shaft 105. The gears are connected by transmission, the top of the top cover 2 is fixedly connected with the batching hopper 3, and the diameter of the bottom of the top cover 2 is consistent with the diameter of the top of the top cover 2, and the top cover 2 is set in a trapezoidal shape, and the batching hopper 3 is set in...

Embodiment 2

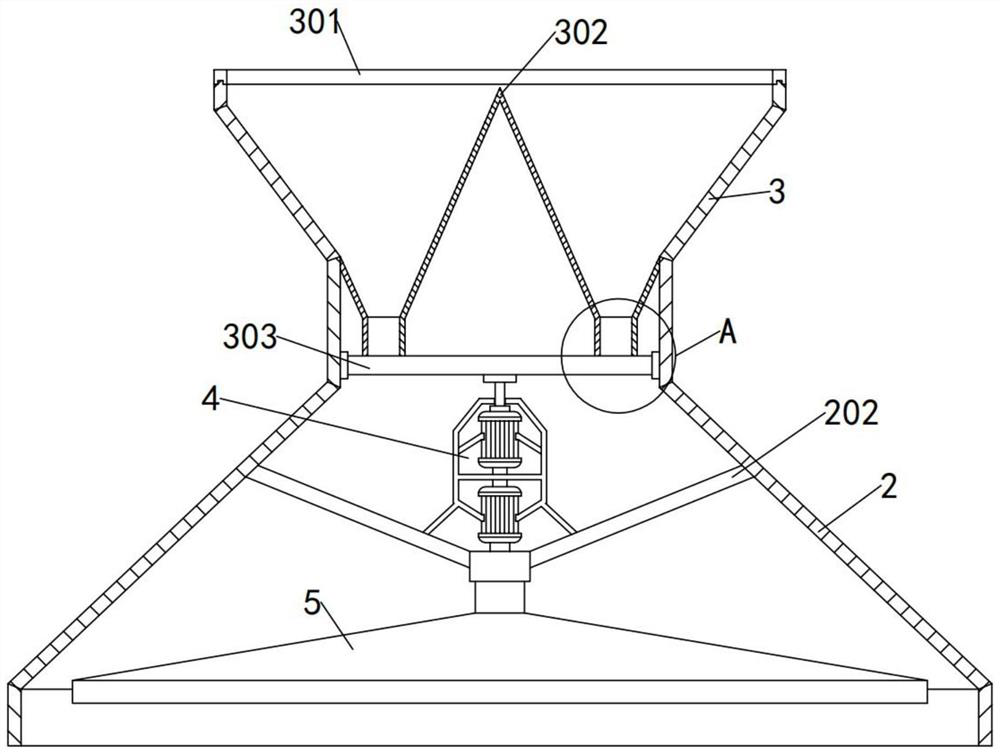

[0043] see Figure 5 , Figure 7 and Figure 8 , in this embodiment, the top of the diversion turntable 5 is embedded with a central rod 501, the side of the diversion turntable 5 is provided with a frame 502, a support rod 504 is fixedly connected between the inner side of the frame 502 and the center rod 501, and the top of the support rod 504 is fixedly connected There is a panel 503, and there are four groups of panels 503, and the length of each group is divided into three sections with equal lengths. The upper surface of the panel 503 is fixedly connected with a deflector 505, and the deflector 505 is installed on the three-section panel in turn. of the segment.

[0044] In this embodiment, when the electromagnetic shielding material falls above the diversion turntable 5, that is, it falls above the panel 503, since the position where the electromagnetic shielding material falls through the tube 3031 is fixed, when the diversion turntable 5 rotates , the electromagnet...

Embodiment 3

[0046] see Figure 9-10 , in this embodiment, the top of the central rod 501 is fixedly connected with a sleeve 5011, and a screw hole is provided in the sleeve 5011 to facilitate the power transmission between the diversion turntable 5 and the driving mechanism 4, and the central rod 501 is hollow to The bottom is open, and the center rod 501 is connected with an exhaust fan 5012 in rotation. The bottom of the center rod 501 is nested with a bottom filter 5013, and the cross section of the bottom filter 5013 is an arc shape with the center protruding downward. The lower curved tube 5014 is embedded inside, and the lower curved tube 5014 is arranged above the panel 503, and the lower curved tube 5014 is in the shape of an L bent downward as a whole, and the end of the lower curved tube 5014 points to the upper surface of the panel 503, and the panel 503 is embedded inside An air guide tube 5031 is provided, and the air guide tube 5031 is connected to the inside of the center r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com