Titanium alloy sealing process

A titanium alloy and process technology, which is applied in the field of titanium alloy sealing technology, can solve the problems of reduced mechanical properties and enlarged grains, so as to avoid surface treatment, solve the problem of enlarged grains, and improve sealing performance and insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

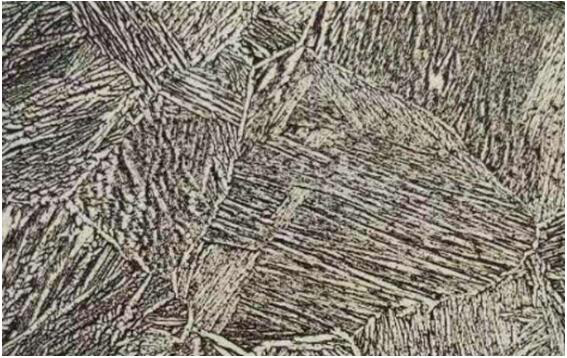

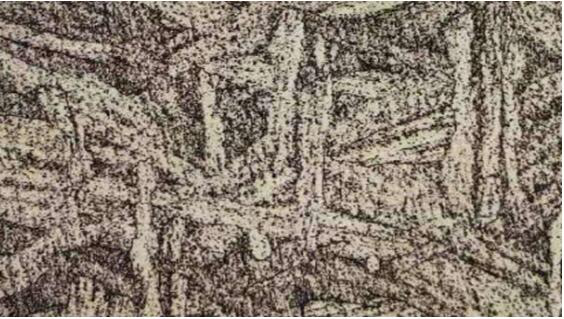

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the invention, and are not intended to limit the scope of the present invention.

[0012] A titanium alloy sealing process, comprising the following steps:

[0013] (1) Assemble the metallized and nickel-plated ceramic insulator with the lead wire and the titanium alloy shell;

[0014] (2) Put the sealing position into the solder;

[0015] (3) Put the assembled product into the vacuum furnace;

[0016] (4) Adjust the temperature of the vacuum furnace to 800~810°C for sealing, and the holding time is 10 minutes;

[0017] (5) Take out the product to check the welding quality.

[0018] In order to improve the sealing quality, ensure that the sealing is reliable and in place. The solder put into step (2) of the titanium alloy sealing process is silver-copper solder.

[0019] In order to improve product p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical insulator | aaaaa | aaaaa |

| electrical insulator | aaaaa | aaaaa |

| electrical insulator | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com