Stirrer with angle-adjustable stirring blades

A stirring blade and adjustable technology, applied in mixers with rotary stirring devices, mixer accessories, chemical instruments and methods, etc., can solve the problems of low mixing uniformity, inconvenience, poor mixing effect, etc., and reduce the mixing processing time. , the effect of increasing the mixing effect and increasing the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

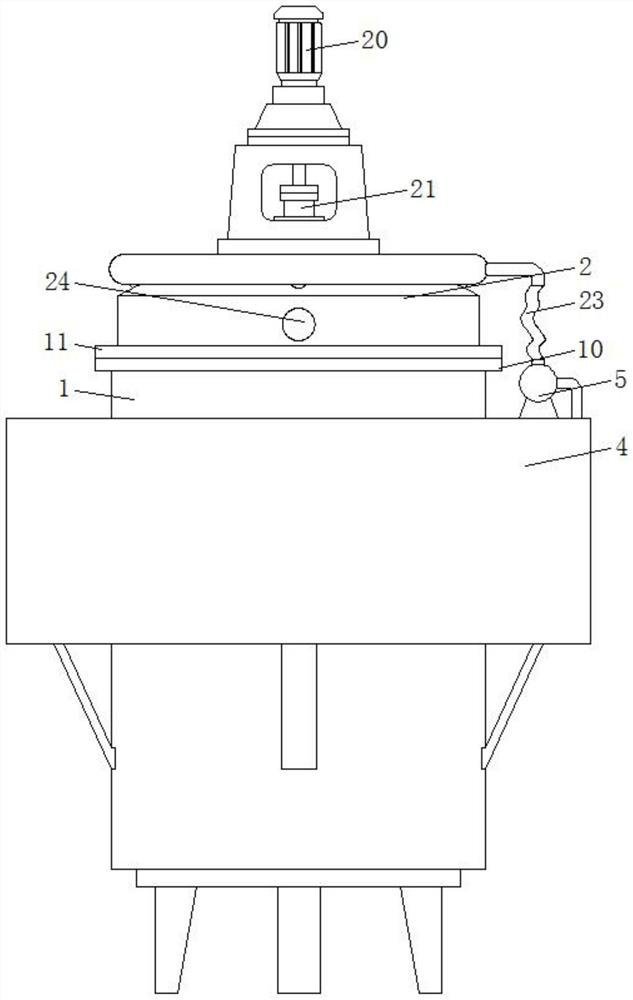

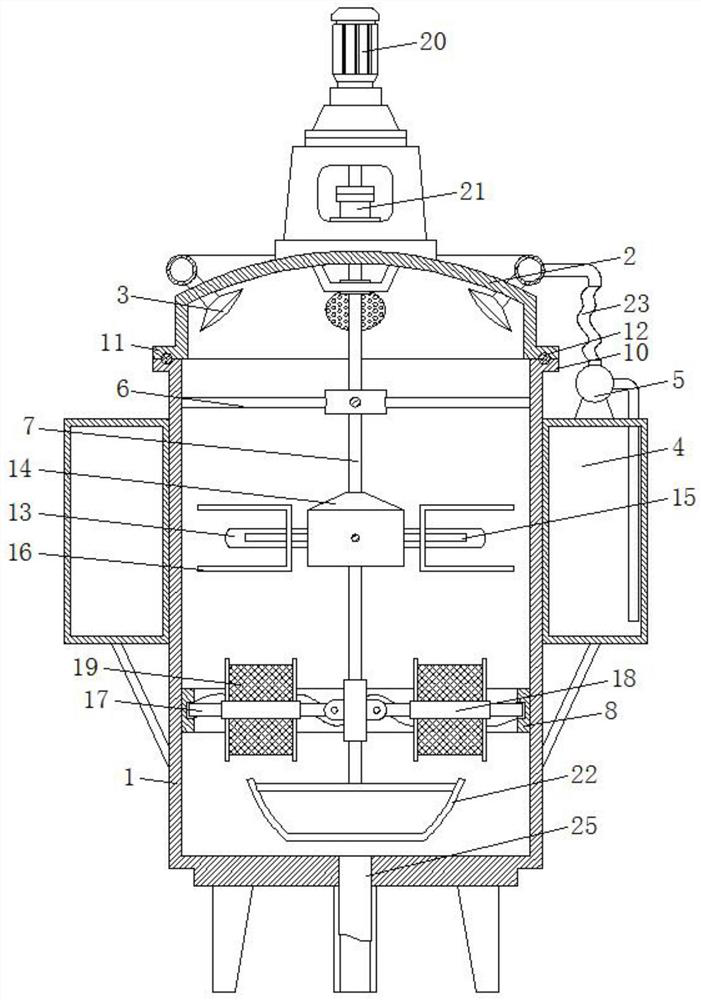

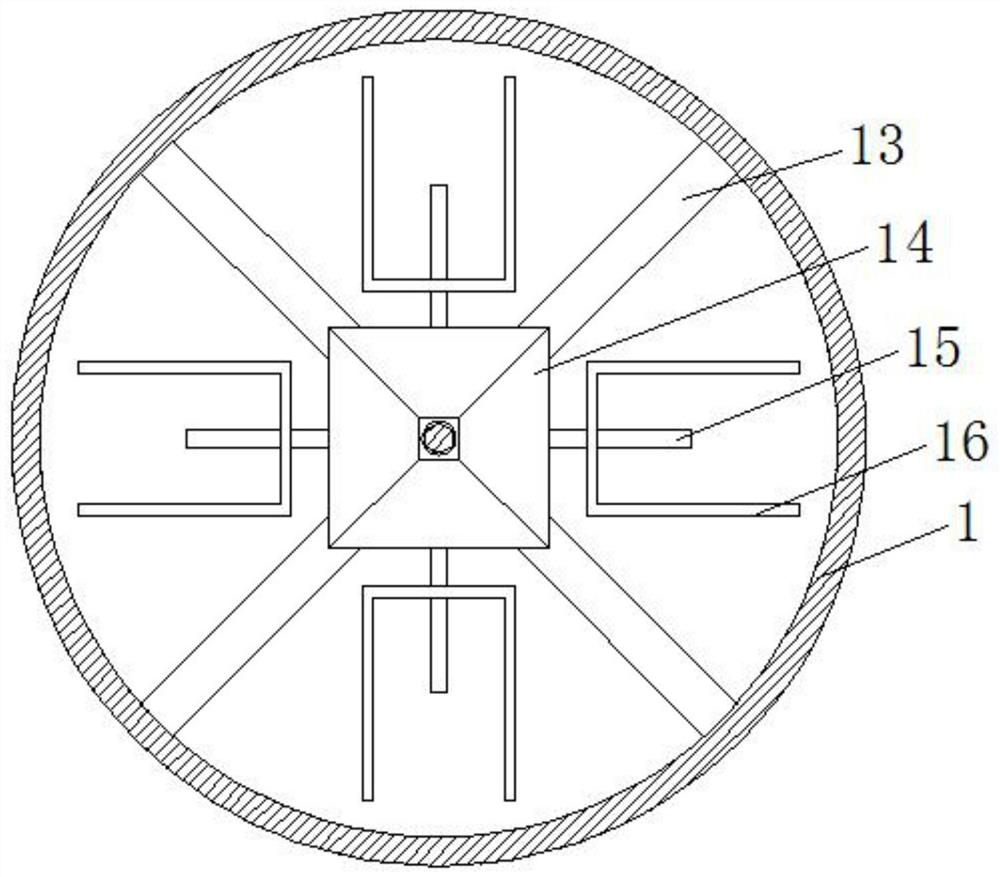

[0025] according to figure 1 , 2 , 3, 4, and 5, this embodiment provides an agitator with an adjustable agitating blade angle, including a self-cleaning tank mechanism and an adjustable stirring mechanism, and the self-cleaning tank mechanism includes a tank body 1 and an upper cover plate 2 , a sealing mechanism, an inclined spray head 3, a clean water tank 4 and a water pump 5, an upper cover plate 2 is arranged above the tank body 1, and an inclined spray head 3 is arranged symmetrically on the inner lower side of the upper cover plate 2, and the A clear water tank 4 is arranged on the outside of the tank body 1, and a water pump 5 is arranged above the clear water tank 4, and the water pump 5 is connected to the inclined spray head 3 through pipelines. Mechanism, fixed ring 8, guide track groove 9 and hinged mixing mechanism, the upper side of the tank body 1 is provided with a connecting frame 6, and a main shaft 7 is installed between the upper cover plate 2 and the con...

Embodiment 2

[0032] according to Image 6 , 7As shown in , 8, this embodiment provides a stirrer with an adjustable stirring blade angle, the bottom of the tank body 1 is symmetrically provided with a foot mechanism, and the foot mechanism includes a support foot 26, a contraction groove 27, a telescopic rod 28 and Universal wheel 29, the bottom of the tank body 1 is symmetrically provided with support feet 26, and the support feet 26 are symmetrically provided with four groups, and the support feet 26 are provided with shrinkage grooves 27, and telescopic grooves 27 are provided in the shrinkage grooves 27. Rod 28, the lower end of the telescopic rod 28 is fixed with a universal wheel 29, and the universal wheel 29 is accommodated in the contraction groove 27, so as to avoid the need to use auxiliary hoisting equipment for handling when moving the device, saving time, effort and convenience. A fan 30 is provided below the upper cover plate 2, and a heating wire 31 is provided below the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com