Construction device for washing coal ash stirring device

A stirring device and construction device technology, applied in the direction of packaging, transportation and packaging, containers, etc., can solve the problems of poor cleaning effect, achieve good cleaning effect, various rotation directions, and improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

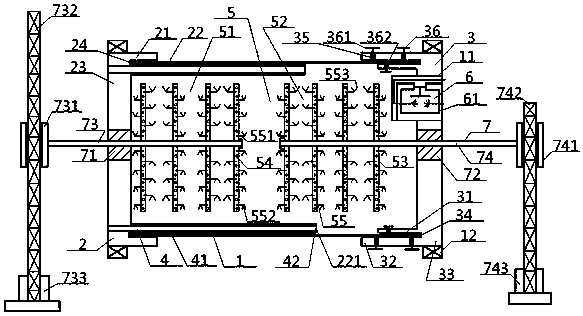

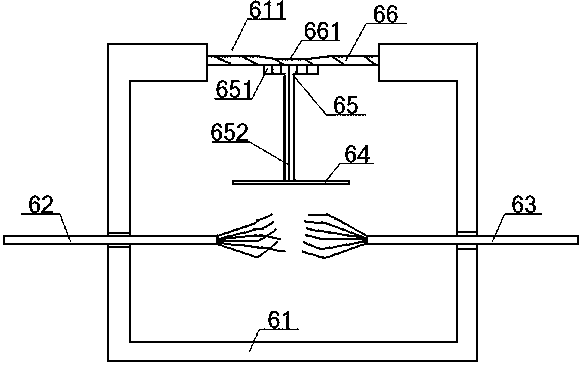

[0027] see Figure 1 to Figure 2, a construction device for cleaning a fly ash mixing device, comprising a fly ash tank 1, an inner cleaning integration 5 and a main stirring shaft 7, the inside of the fly ash tank 1 is provided with an inner cleaning integration 5, the inner The inside of the cleaning integration 5 is connected to the middle part of the main stirring shaft 7, and the left and right ends of the main stirring shaft 7 pass through the left and right ends of the fly ash tank 1 and then extend to the outside of the fly ash tank 1;

[0028] The left and right ends of the main stirring shaft 7 are respectively connected with the left rotary bearing 71 and the right rotary bearing 72, and the left rotary bearing 71 and the right rotary bearing 72 are respectively located in the middle of the left fixed seat 2 and the right f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com