Automatic crimping equipment for primary terminal of adjustable mutual inductor

A technology of crimping equipment and transformers, applied in the direction of inductance/transformer/magnet manufacturing, connection, circuit/collector components, etc., can solve problems such as low assembly efficiency, inability to guarantee force, and inability to improve yield rate, etc., to achieve Improve crimping efficiency and crimping success rate, reduce labor intensity, avoid deformation or even damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

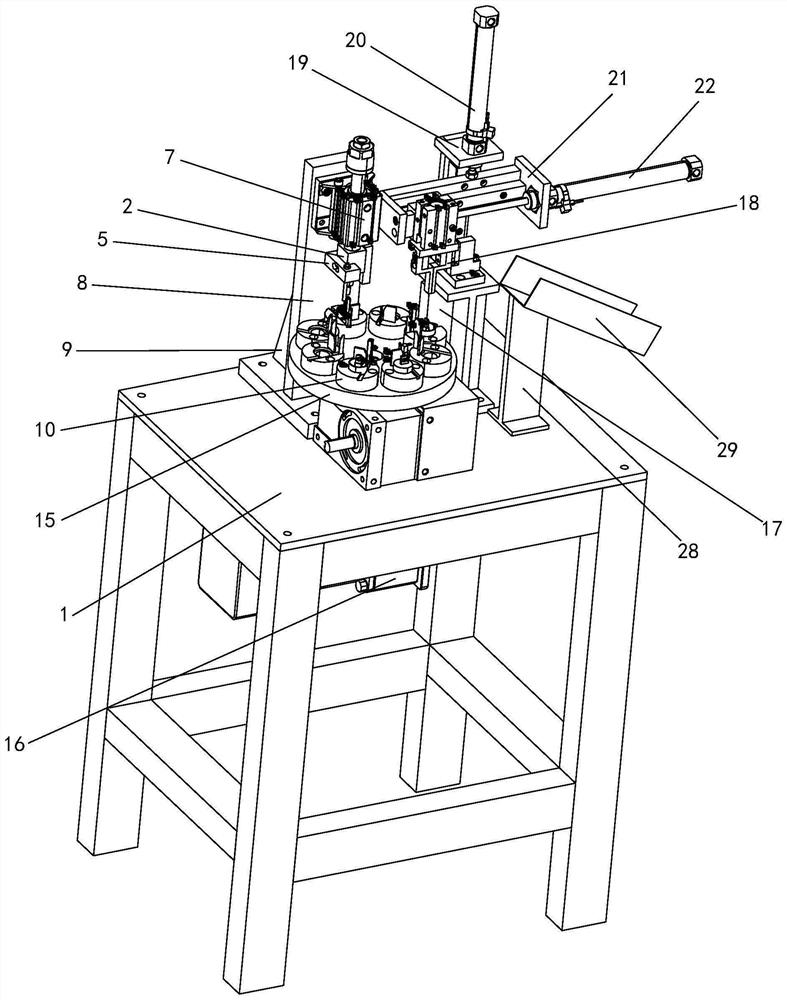

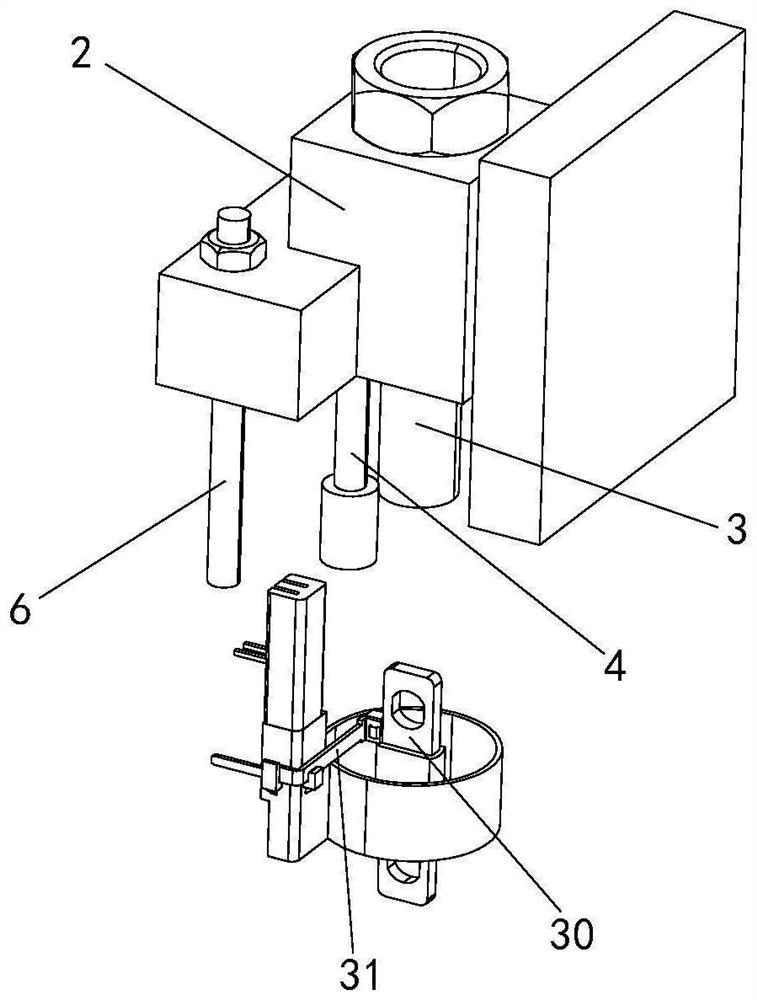

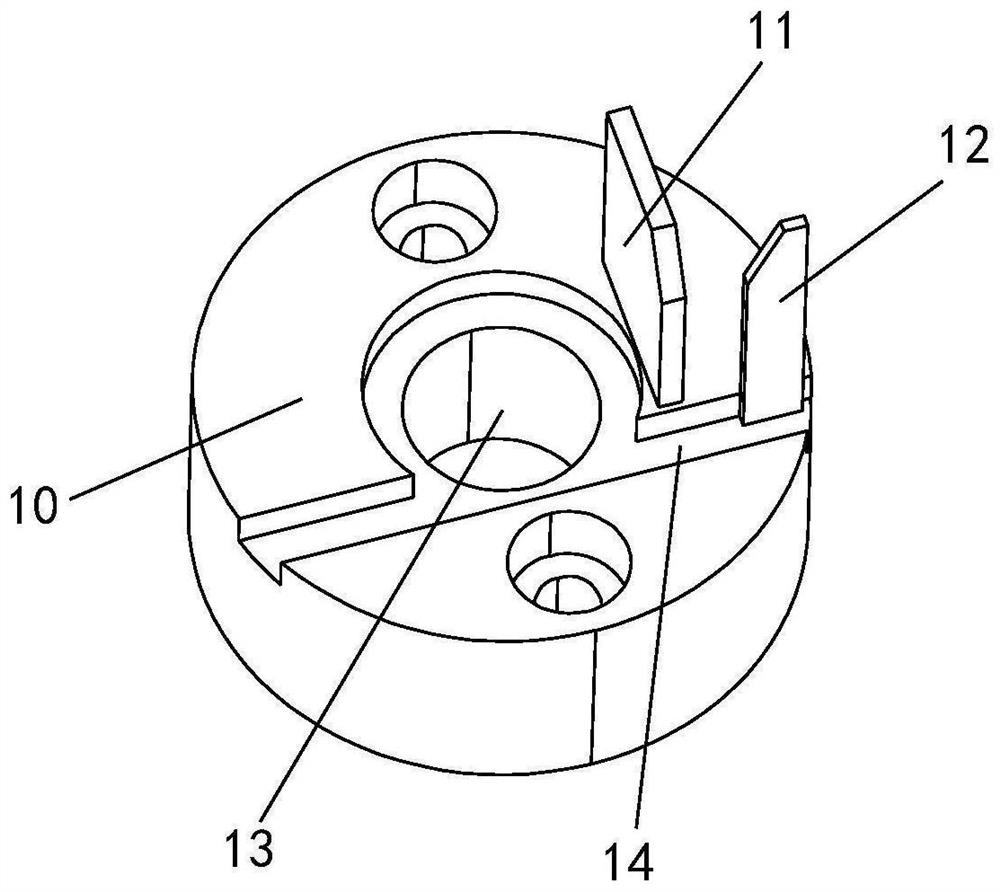

[0026] Such as Figure 1-5 As shown, the present invention provides an automatic crimping equipment for the primary terminal of an adjustable transformer, including a workbench 1, a driving structure arranged on the workbench 1, a crimping seat arranged on the workbench 1 and a crimping seat arranged on the workbench The crimping structure on 1, the driving structure drives the crimping structure to reciprocate toward the crimping seat, the crimping structure includes the connecting seat 2, the first crimping column 3 and the second crimping column arranged at the lower end of the connecting seat 2 Connecting post 4, the first crimping post 3 and the second crimping post 4 respectively correspond to different positions of the primary terminals on the crimping seat, and the upper end of the connecting seat 2 is fixed to the telescopic end of the driving structure.

[0027] The primary terminal includes an insert and an L-shaped or Z-shaped terminal bracket 31 arranged on the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com