Mining area pipeline construction mobile monitoring system

A monitoring system, mobile technology, applied in the direction of cleaning hollow objects, measuring devices, instruments, etc., can solve the problems of time-consuming and labor-intensive monitoring, reduce the service life of pipelines, and long transportation distances of pipelines, so as to reduce labor intensity and ensure use effect, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

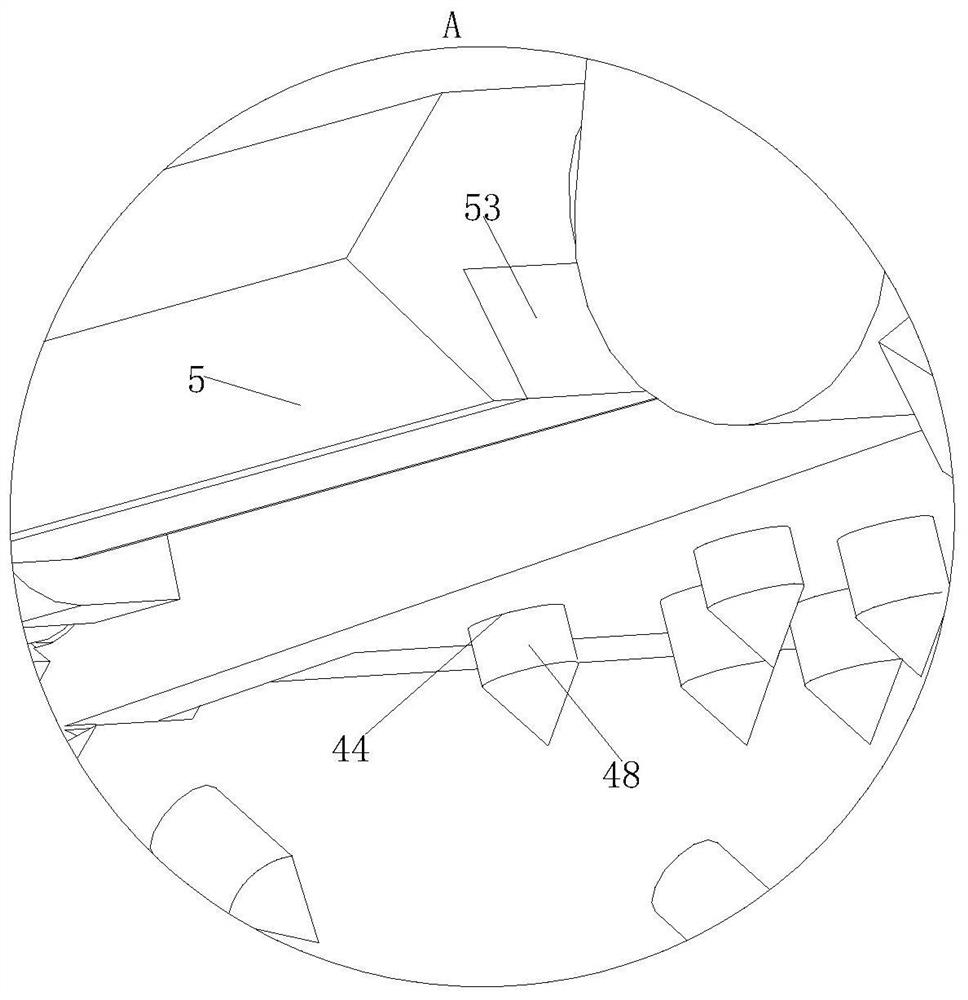

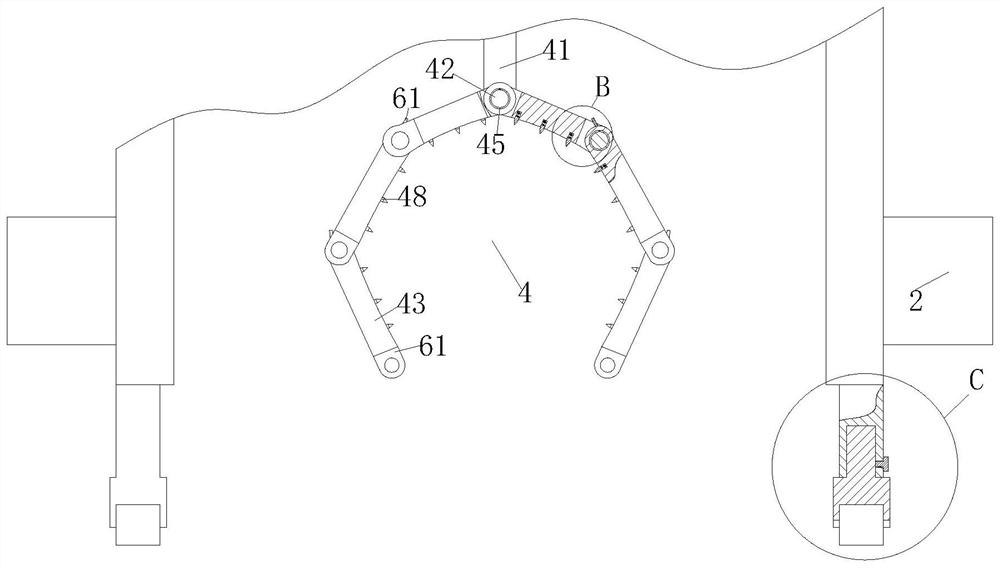

[0047] As an embodiment of the present invention, the monitoring mechanism 4 includes a connecting rod 41, a hinged shaft 42 and a monitoring block 43; the number of the connecting rods 41 is two, and the two connecting rods 41 are located in the tube when the present invention is used. The two ends of the road shaft, two connecting rods 41 are fixedly connected with the two ends of the hinge shaft 42; the hinge shaft 42 is coaxially hinged with two monitoring blocks 43 through the No. 1 torsion spring 45; the two monitoring blocks 43 Symmetrically distributed, two monitoring blocks 43 are provided with monitoring slots 44 on the end faces forming an obtuse angle; the No. 1 torsion spring 45 makes the two monitoring blocks 43 rotate towards each other; the monitoring slots 44 are evenly distributed, The groove bottom of monitoring groove 44 is fixedly connected with pressure sensor 46; Described pressure sensor 46 is fixedly connected with No. 1 spring 47 near the end face of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com