Surface cleanliness testing device and method

A surface cleaning and testing device technology, applied in the direction of measuring devices, surface tension analysis, surface/boundary effects, etc., can solve the problems of high misjudgment rate, complex structure, inconvenient operation, etc., to achieve improved accuracy and reliability, high The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

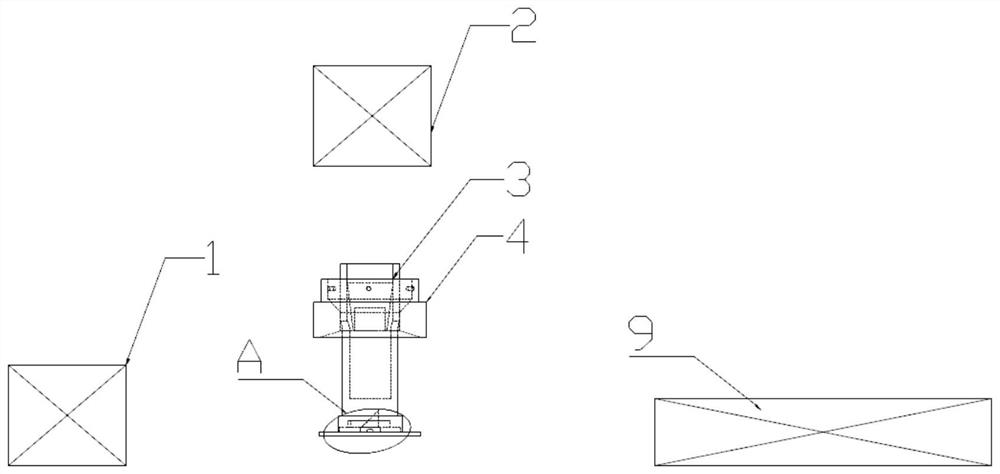

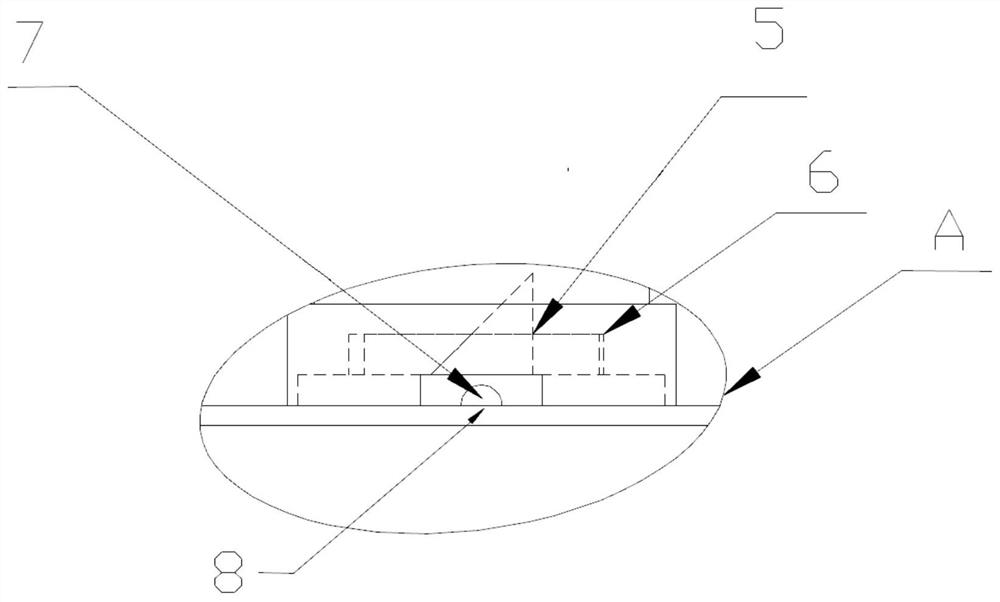

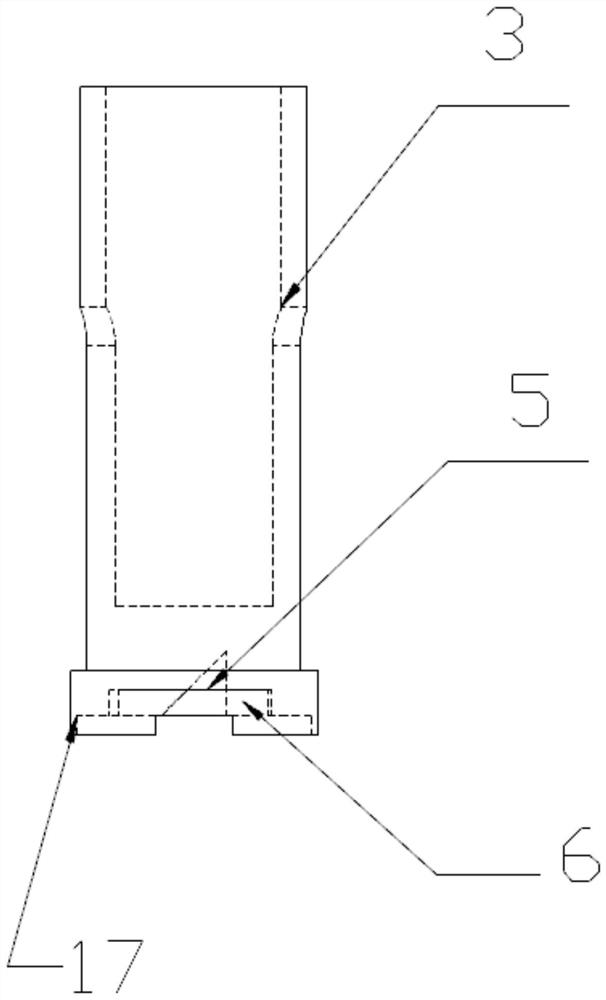

[0071] Such as Figure 1-7As shown, a surface cleanliness testing device includes a background light source 1, a codirectional light source 2, a bracket 3, a coaxial ring light source 4, a prism 5, a prism fixing bracket 6, a droplet 7, a sample to be tested 8 and an imaging system 9 , the prism 5 is fixed on the prism fixing bracket 6 through the top screw fixing screw, the prism fixing bracket 6 is connected with the bottom of the bracket 3 through the fixing screw, the coaxial ring light source 4 is fixed on the bracket 3 through the fixing screw, and is located on the prism 5 Above, the prism 5, the prism fixing bracket 6, the bracket 3 and the coaxial ring light source 4 are combined into a top-view prism assembly, the background light source 1 and the imaging system 9 are respectively located on both sides of the top-view prism assembly, and the same direction light source 2 Located on the top of the top-viewing prism assembly, the tested sample 8 is provided with a drop...

Embodiment 2

[0093] The optical path structure proposed by the surface cleanliness test device in this embodiment, the test method proposed by the surface cleanliness test device are the same as the first embodiment, and the surface cleanliness test device is roughly the same as the embodiment, the only difference is that this embodiment The annular coaxial light source 4 in the example is a visible light spectrum light source.

[0094] The invention realizes UV top view imaging, coaxial top view and background light side view in the same image by simultaneously providing background light source, coaxial light source, coaxial ring light source and other light source combinations, and through a 90-degree prism structure. The three conditions are imaged in the same image, thereby effectively solving the purpose of the cleanliness test under the influence of chemical diversity and surface structure. At the same time, combined with the optimized cleanliness test process provided by the utility ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension value | aaaaa | aaaaa |

| Surface tension value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com