Collaborative method and collaborative device for multichannel RGB color calibration

A color calibration and multi-channel technology, applied in the collaborative method and collaborative device field of multi-channel RGB color calibration, can solve the problems of only waiting, wasting time costs and power consumption costs, etc., to save time, improve efficiency, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

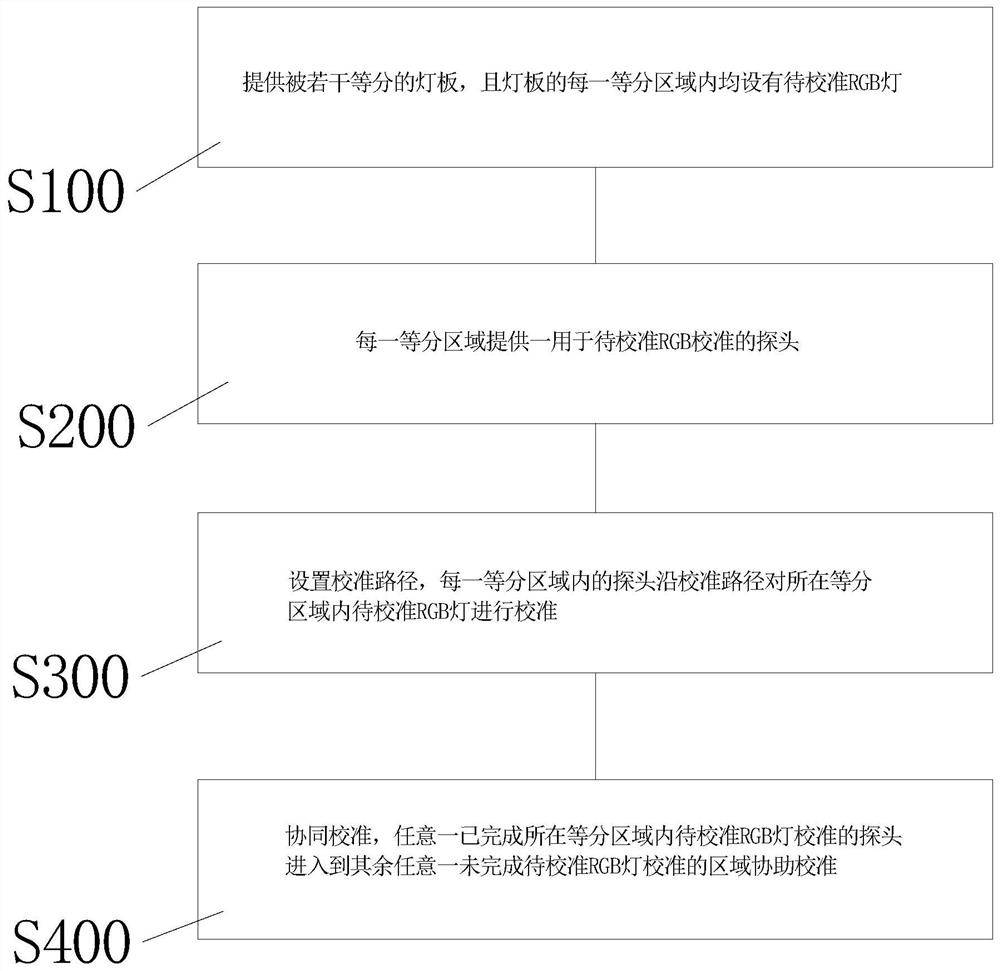

[0043] see figure 1 As shown, a collaborative method for multi-channel RGB color calibration includes the following steps:

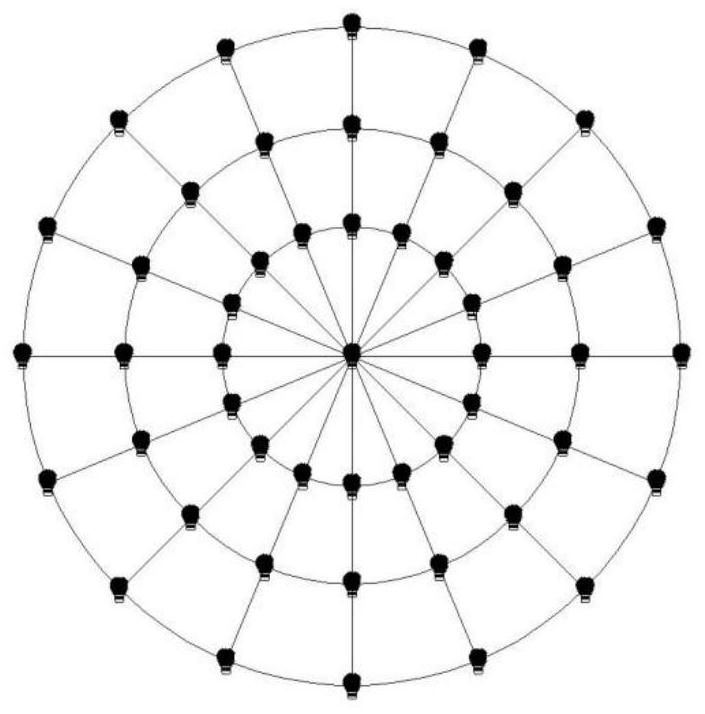

[0044] Step S100: Provide the lamp board 5 divided into several equal parts, and RGB lamps to be calibrated are provided in each equal division area of the lamp board 5; in this embodiment, there are multiple concentric regular polygons on the lamp board 5, and the RGB lamps to be calibrated It is set at the intersection of the regular polygon and the bisector of the regular polygon, and the RGB lamp to be calibrated is set at the concentric point of the concentric regular polygon.

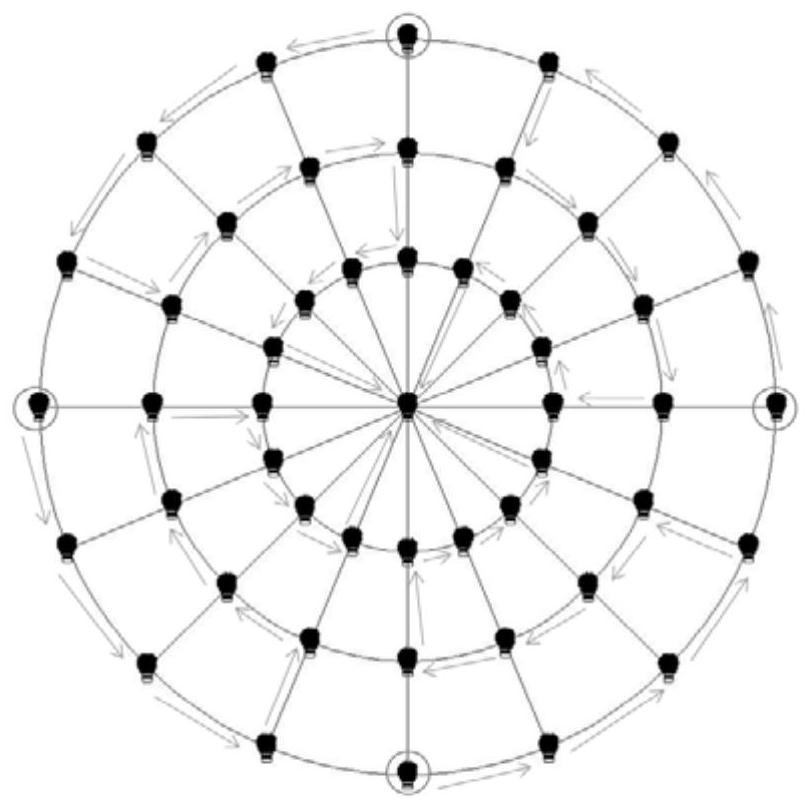

[0045] see figure 2 As shown, in the specific example of this embodiment, the lamp board 5 is a PCB board, and three concentric circles are arranged on the PCB board. There are three concentric circles, and the adjacent two concentric circles between adjacent two concentric circles The distance between the circles is the same, first divide the three concentric circles i...

Embodiment 2

[0057] see Figure 5 As shown, a cooperative device for multi-channel RGB color calibration includes a lamp board 5, a calibration device, a casing 3 and a cooperative control device. The bottom of the casing 3 is provided with a base 6, and the lamp board 5 is installed on the base 6, there are several equally divided areas on the lamp board 5, and RGB lamps to be calibrated are arranged in each equally divided area, and the calibration device includes a bracket, a probe 4 corresponding to each equally divided area, and a probe 4 corresponding to each probe 4 The driving device 1, the bracket is arranged inside the shell, and is located above the base 6, the driving device 1 is installed on the bracket, the driving device 1 drives and connects the probe 4, and the driving device 1 is electrically connected to control the driving device 1 to drive the probe 4 A collaborative control device for calibrating the RGB lamp to be calibrated in the area where the probe 4 is located. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com