Calibration system and calibration method of temperature sensor chip

A temperature sensor and calibration system technology, applied in thermometer testing/calibration, thermometers, instruments, etc., can solve the problems of long calibration time, high cost, complicated construction, etc., and achieve the effect of short calibration time, low cost and high calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

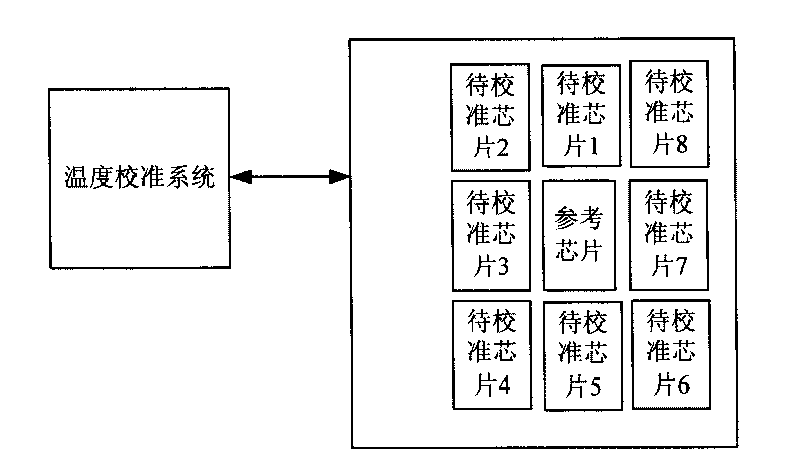

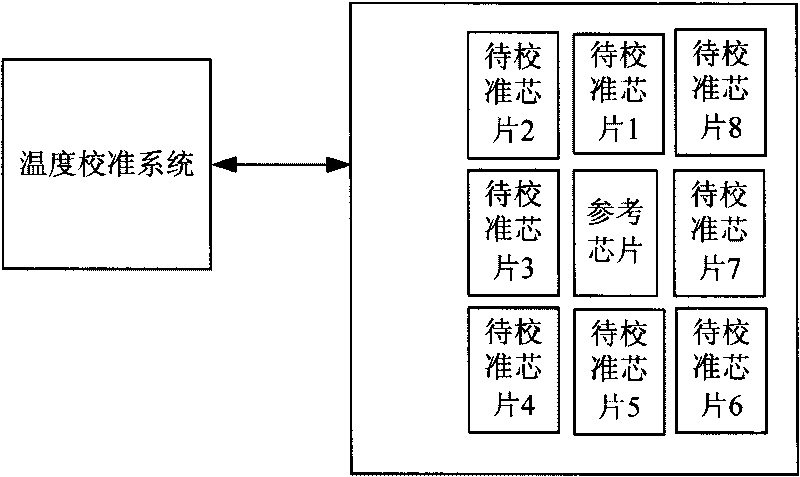

[0026] like figure 2 As shown, the calibration system of the temperature sensor chip of the present invention includes a test board and a temperature calibration system; the test board is provided with a temperature sensor reference chip (REF IC) and a plurality of chips to be calibrated, and each chip is uniformly addressed and discharged on the test board , so that each chip has a different device address; each chip communicates with the temperature calibration system through a unified digital interface.

[0027] The temperature calibration system is used to read the temperature data of the reference chip and the chip to be calibrated, and form calibration data to calibrate the temperature sensor chip.

[0028] The accuracy of the temperature sensor reference chip is higher than that of the chip to be calibrated. The reference chip is used to collect the ambient temperature information of the chip to be calibrated.

[0029] The number of chips to be calibrated can be adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com