Inclined rotary combustion device for efficiently disposing solid waste

A combustion device, rotary technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problem of reducing the heat utilization efficiency of the system, and achieve the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

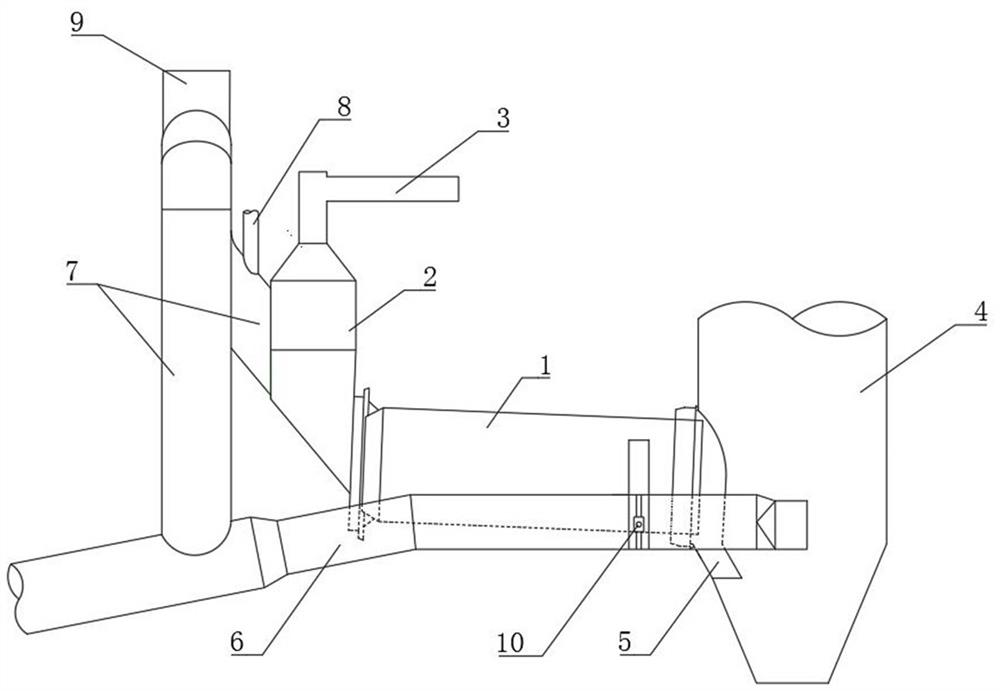

[0060] Such as Figure 1-Figure 5 Shown:

[0061] This embodiment provides an inclined rotary combustion device for efficiently disposing of solid waste, including a decomposition furnace 4, a rotary furnace 1, a mixing feeding chamber 2, a feeder 3 and a tertiary air main pipe 6, wherein:

[0062] The tail of the rotary furnace 1 is connected to the mixing and feeding chamber 2, and the head is connected to the calciner 4;

[0063] The top of the mixed feeding chamber 2 is provided with a feeder 3;

[0064] The tertiary air main pipe 6 is provided with a tertiary air sub-pipe 7 connected to the mixing feeding chamber 2;

[0065] The tertiary air main pipe 6 communicates with the calciner 4;

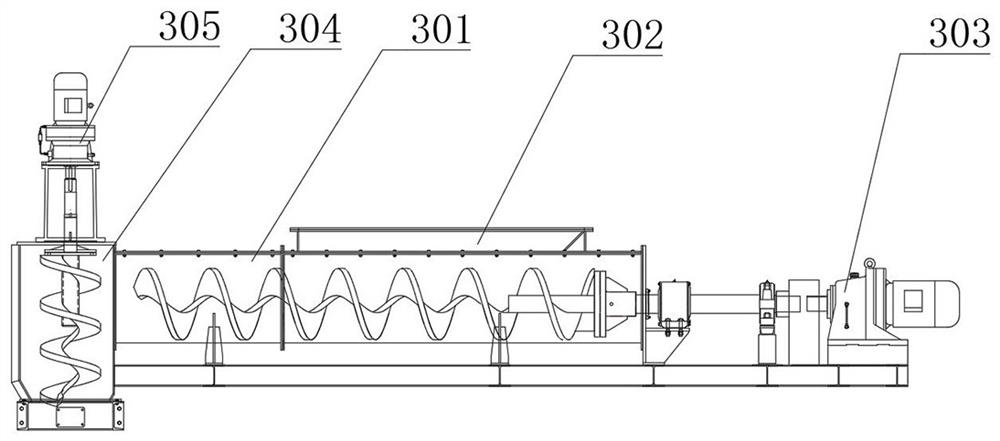

[0066] The feeder 3 is a horizontal + vertical bidirectional double-screw material conveyor;

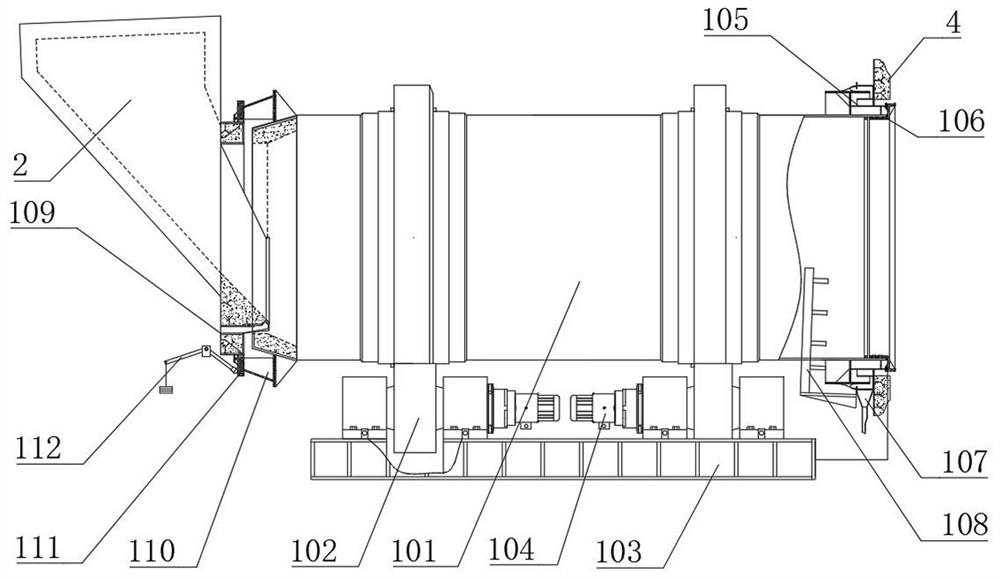

[0067] The rotary furnace 1 includes a rotary furnace cylinder 101, a support wheel device 102, a cold air jacket 105, an iron back plate 106 and a return box 110;

[0068] The rotary furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com