Biological drying system

A biological drying system and biological drying technology, applied in the field of sludge treatment, can solve the problems of serious environmental pollution, long cycle, large floor area, etc., and achieve the effects of reducing costs, improving efficiency, and uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

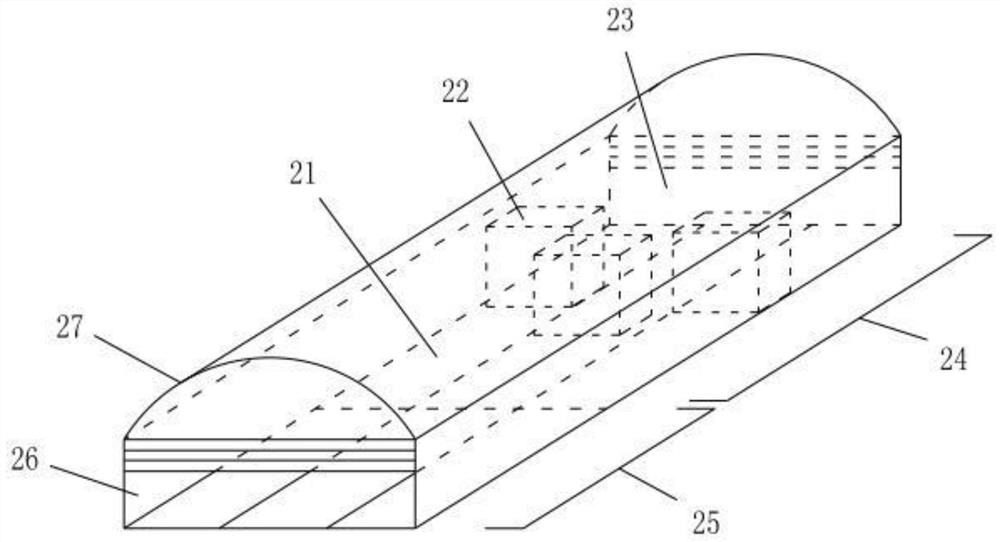

[0021] The present invention is described below in conjunction with accompanying drawing.

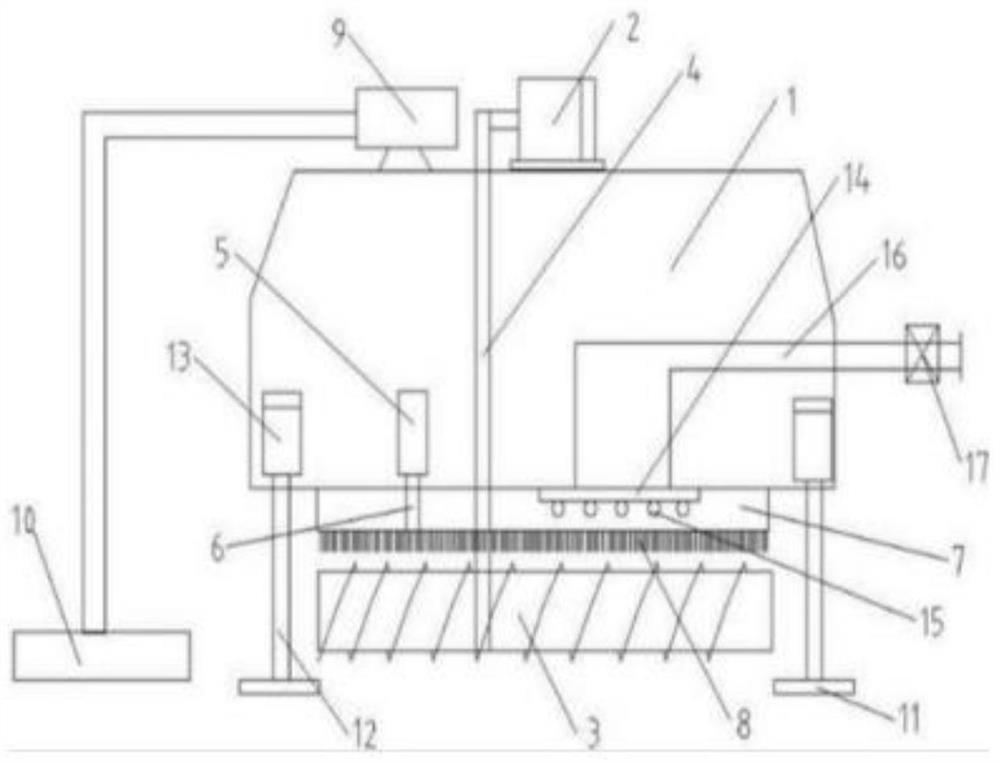

[0022] as attached figure 1 As shown, a biological drying system according to the present invention includes a biological drying tank 21 and a biological drying integrated machine 22. The biological drying tank 21 is provided with multiple channels, and the top of the multi-channel biological drying tank 21 is provided with The ceiling 27 forms a semi-enclosed sludge biological drying site; each biological drying tank 21 has a feed end 23, a drying area 24, a storage area 25 and a discharge end 26 arranged in sequence, and the biological drying is integrated The machine 22 works in the drying area 24, drying the sludge in the drying area 24, and sending the sludge that meets the requirements to the storage area 25 for buffering, and then discharging according to needs; the drying area 24 and the storage The area 25 is equipped with a gas flow system, the drying area 24 adopts strong ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com