Fracturing nipple and fracturing string comprising fracturing nipple

A pup joint and fracturing technology, which is applied in the direction of wellbore/well valve device, production fluid, wellbore/well parts, etc., can solve the problems affecting the construction process and the sliding sleeve cannot be opened smoothly, so as to achieve reliable construction and avoid Early rupture to ensure safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

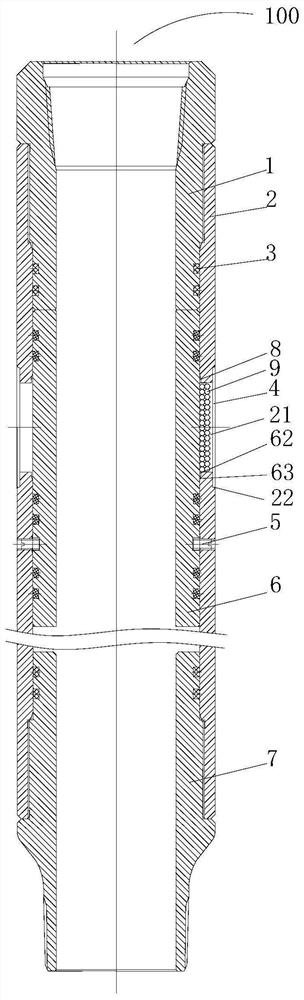

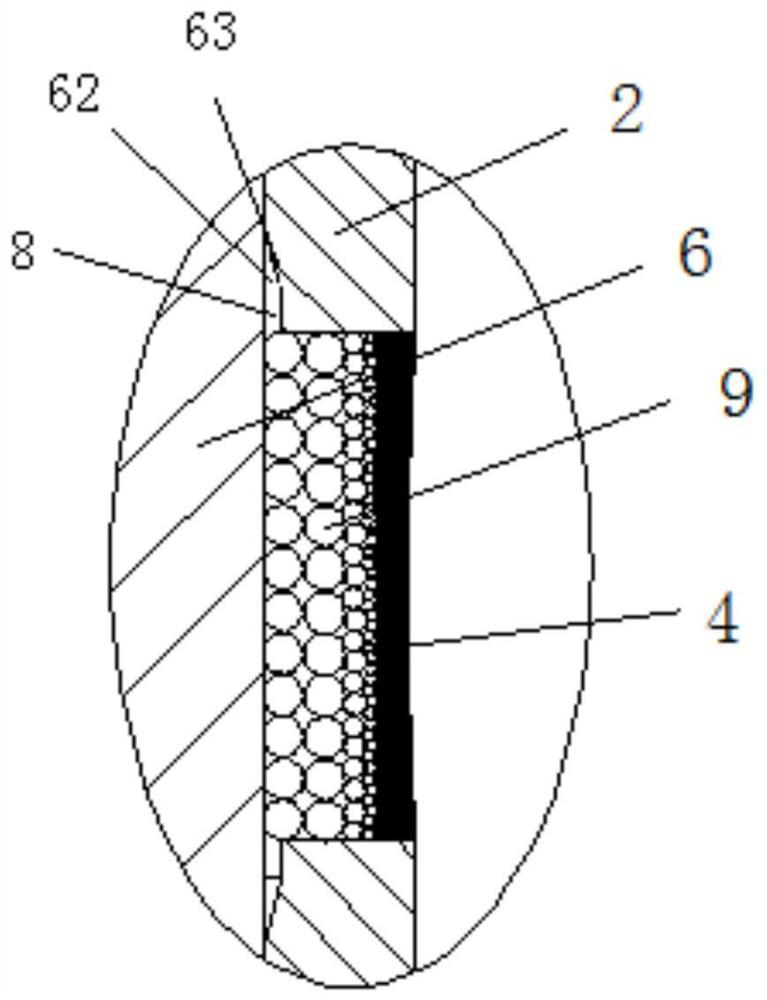

[0025] figure 1 A frac sub 100 according to the present invention is shown. Such as figure 1 As shown, the fracturing sub 100 includes an outer cylinder 2 , an inner sliding sleeve 6 , a rupture sleeve 4 and a support member 9 . A fracturing hole 21 capable of communicating with the inside and outside is provided on the wall of the outer cylinder 2, and is used as a channel for fracturing operation. The inner sliding sleeve 6 is arranged in the inner cavity of the outer cylinder 2, and is used to close the fracturing hole 21 in the initial state. For example, the inner sliding sleeve 6 is arranged on the inner wall of the outer cylinder 2 through the shear pin 5 . After the inner sliding sleeve 6 receives the axial downward force and reaches the shearing pressure of the shear pin 5, the shear pin 5 is sheared, so that the inner sliding sleeve 6 can move down relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com