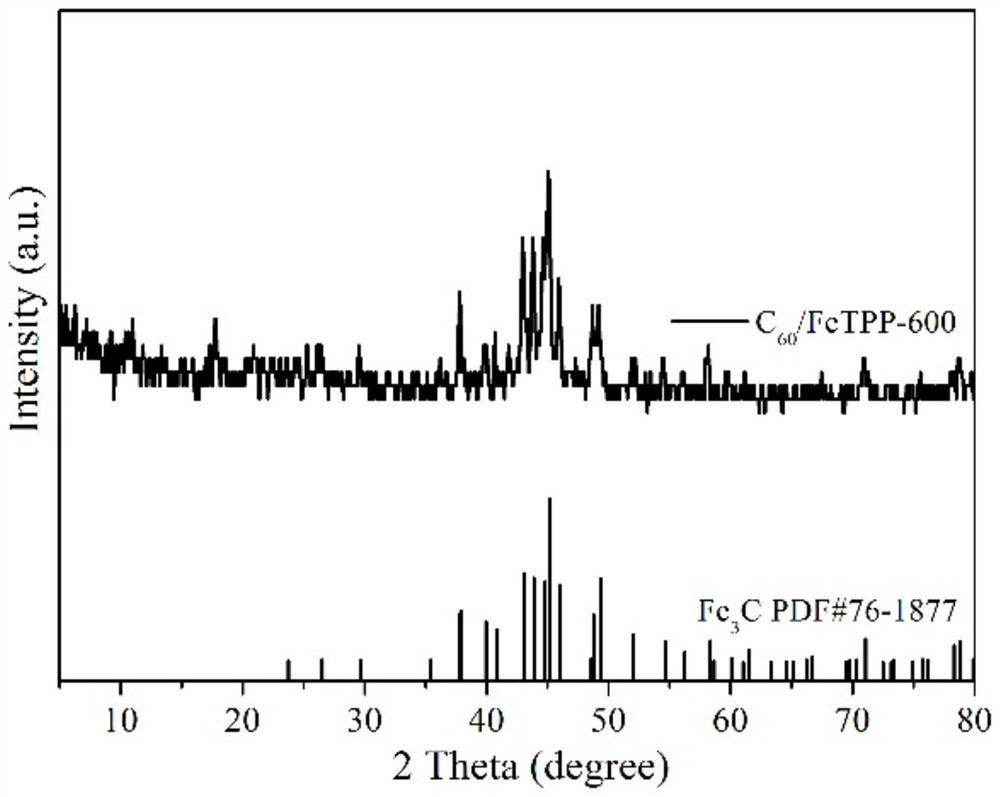

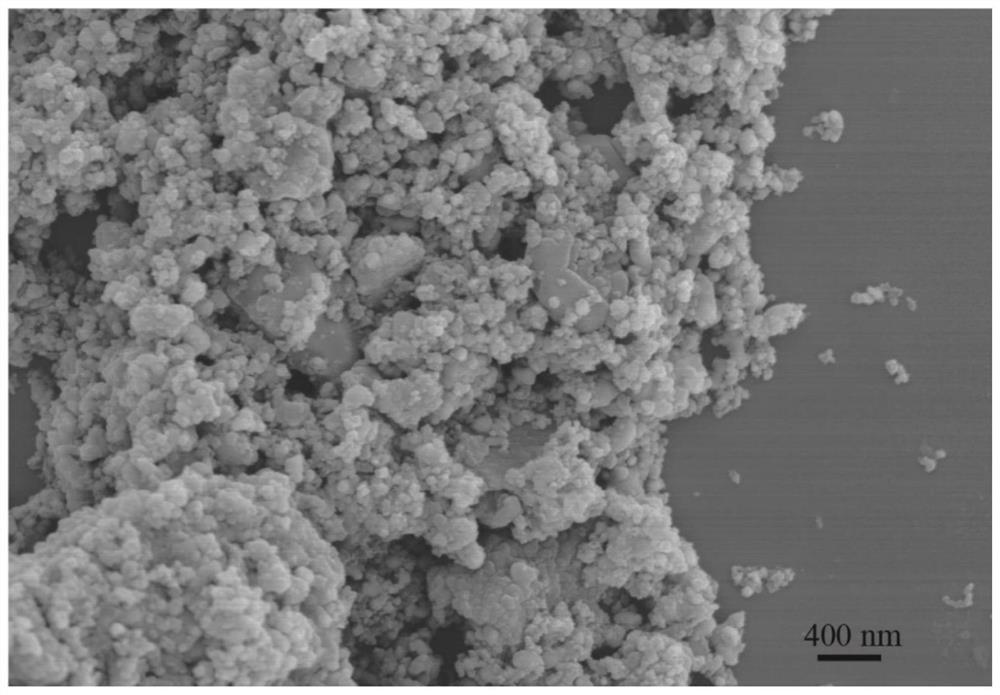

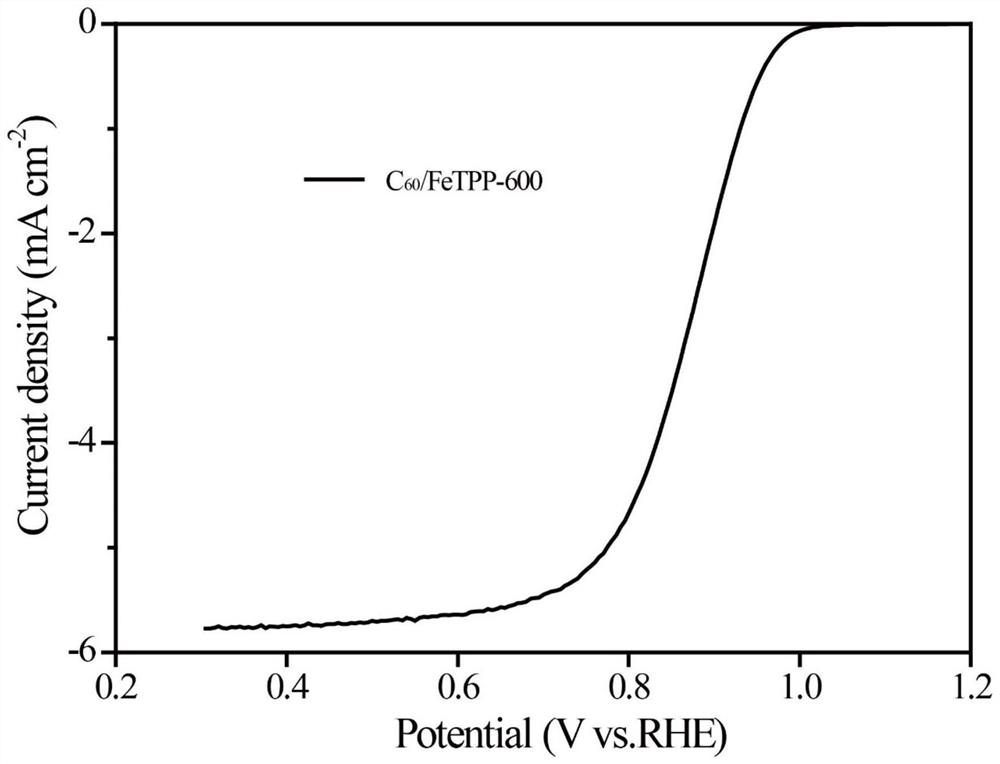

Preparation method of fullerene/tetraphenylferriporphyrin self-assembled structure oxygen reduction electrocatalyst

A technology of tetraphenyl iron and electrocatalyst, which is applied in structural parts, electrodes, circuits, etc., can solve the problems of high cost, poor stability, HER and OER catalysis are not as good as Pt, etc., and achieve self-assembly with complete morphology and low production cost , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of metalloporphyrin: Take 1 mole of tetraphenylporphyrin, 5.4 moles of ferric nitrate nonahydrate and 80 mL of DMF solvent, stir evenly under a nitrogen atmosphere, heat up to 100 ° C and reflux for 6 hours. After the reaction is completed, Naturally cool to room temperature, then add 80mL of ultrapure water to it and let stand for 12h, filter with suction, wash with isopropanol, and dry in vacuum at 60°C for 8h to obtain tetraphenyliron porphyrin;

[0027] 2) Preparation of self-assembled structure: take fullerene C at a mass ratio of 1:1 60 and tetraphenyliron porphyrin were poured into beakers respectively, and 1mg / mL fullerene toluene solution and 0.6mg / mL tetraphenyliron porphyrin suspension in isopropanol were prepared, and the two beakers were covered with a layer After the plastic wrap, put it into an ultrasonic machine for ultrasonic dissolution and dispersion;

[0028] 3) Filter the fullerene toluene solution that has been ultrasonically disper...

Embodiment 2

[0035] 1) Preparation of metalloporphyrin: take 1 mole of tetraphenylporphyrin, 12.8 moles of ferric nitrate nonahydrate and 90 mL of DMF solvent, stir evenly under a nitrogen atmosphere, heat up to 110 ° C and reflux for 6 hours. After the reaction is completed, Naturally cool to room temperature, then add 135mL of ultrapure water and let it stand for 24h, filter with suction, wash with isopropanol, and dry in vacuum at 60°C for 8h to obtain tetraphenyliron porphyrin;

[0036] 2) Preparation of self-assembled structure: take fullerene C at a mass ratio of 1:2 60 and tetraphenyliron porphyrin into beakers respectively, prepare 1.5 mg / mL fullerene toluene solution and 1 mg / mL tetraphenyl iron porphyrin suspension in isopropanol, and cover the two beakers with a layer After the plastic wrap, put it into an ultrasonic machine for ultrasonic dissolution and dispersion;

[0037] 3) Filter the fullerene toluene solution that has been ultrasonically dispersed using a needle filter, ...

Embodiment 3

[0041] 1) Preparation of metalloporphyrin: Take 1 mole of tetraphenylporphyrin, 14 moles of ferric nitrate nonahydrate and 100 mL of DMF solvent, stir evenly under a nitrogen atmosphere, heat up to 120 ° C, condense and reflux for 6 hours, and wait for the reaction to complete Naturally cool to room temperature, then add 200mL of ultrapure water and let it stand for 24h, filter with suction, wash with isopropanol, and dry in vacuum at 80°C for 10h to obtain tetraphenyliron porphyrin;

[0042] 2) Preparation of self-assembled structure: take fullerene C at a mass ratio of 1:3 60 and tetraphenyliron porphyrin into beakers respectively, prepare 2mg / mL fullerene toluene solution, 2mg / mL tetraphenyliron porphyrin suspension in isopropanol, and cover the two beakers with a fresh-keeping layer Put the film into an ultrasonic machine for ultrasonic dissolution and dispersion;

[0043] 3) Filter the fullerene toluene solution that has been ultrasonically dispersed using a needle filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com