Deep purification and impurity removal process for cobalt chloride solution

A technology of deep purification and cobalt chloride, which is applied in the direction of improving process efficiency, etc., can solve the problems of the impact of impurity content, the impact of extraction and impurity removal process, and the enrichment of copper and cadmium in cobalt chloride solution, so as to achieve simple process flow, The effect of reducing product quality and high depth of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

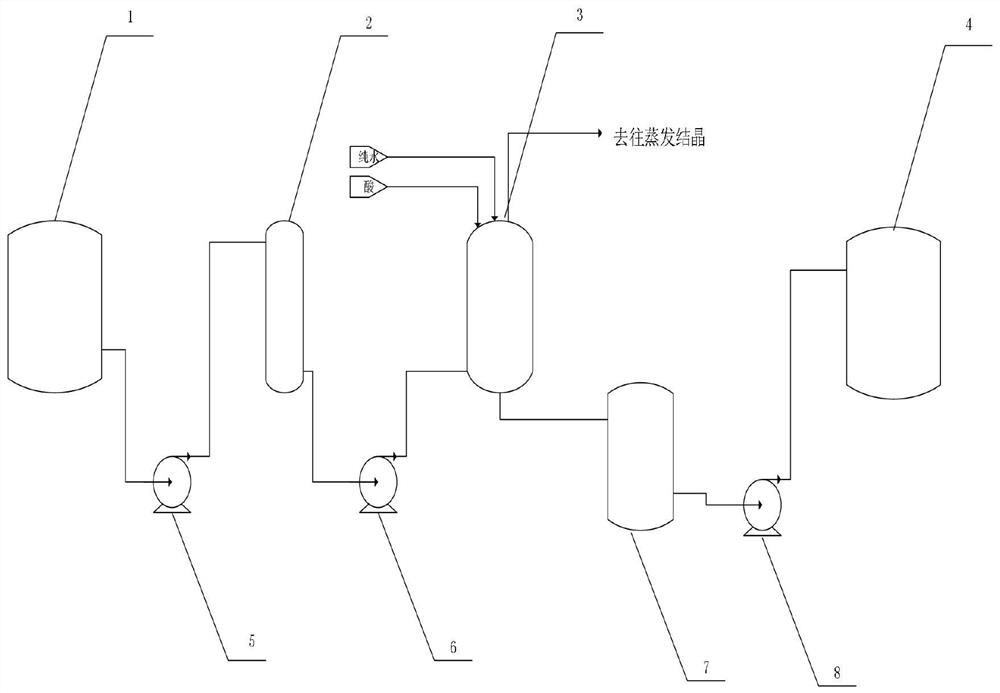

[0011] The invention provides a deep purification and impurity removal process for cobalt chloride solution, which is characterized in that it includes a P507 stripping liquid storage tank, a degreaser, a resin tower, a washing liquid sinking tank, a P507 stripping liquid delivery pump, an oil removal Rear liquid delivery pump, washing liquid low tank, washing water delivery pump, the right end of the P507 stripping solution storage tank is connected with a P507 stripping solution delivery pump, and the right end of the P507 stripping solution delivery pump is connected with a degreasing The right end of the degreaser is connected with a liquid delivery pump after degreasing, and the right end of the degreasing liquid delivery pump is connected with a resin tower, and the right end of the resin tower is connected with a washing liquid low tank, and the washing liquid The right end of the water liquid low level tank is connected with a washing liquid delivery pump, and the right...

Embodiment 2

[0013] When the present invention is in use, as figure 1 As shown, the P507 stripping solution is pumped from the P507 stripping solution storage tank into the degreaser, after being treated by the degreaser, and then pumped into the lower part of the resin tower (resin has been activated) by the deoiled liquid delivery pump, the adsorbed liquid is from The upper end flows out to the evaporation and crystallization process. After the resin in the resin tower is saturated, open the liquid discharge valve at the lower end of the resin tower to drain the cobalt chloride solution in the tower. After the cobalt chloride solution is drained, pure water is pumped into the resin tower with 4BV Wash the resin in the resin tower at a flow rate of / h for 30 minutes, and discharge the washing water into the lower tank of the washing liquid (the resin is washed with pure water for multiple times and reused, and when the utilization rate of the resin is lower than 80%, it is activated once w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com