Method for removing heavy metal ions in household garbage incineration fly ash eluent

A technology of domestic waste incineration and heavy metal ions, which is applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. High reactivity and remarkable effect of treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

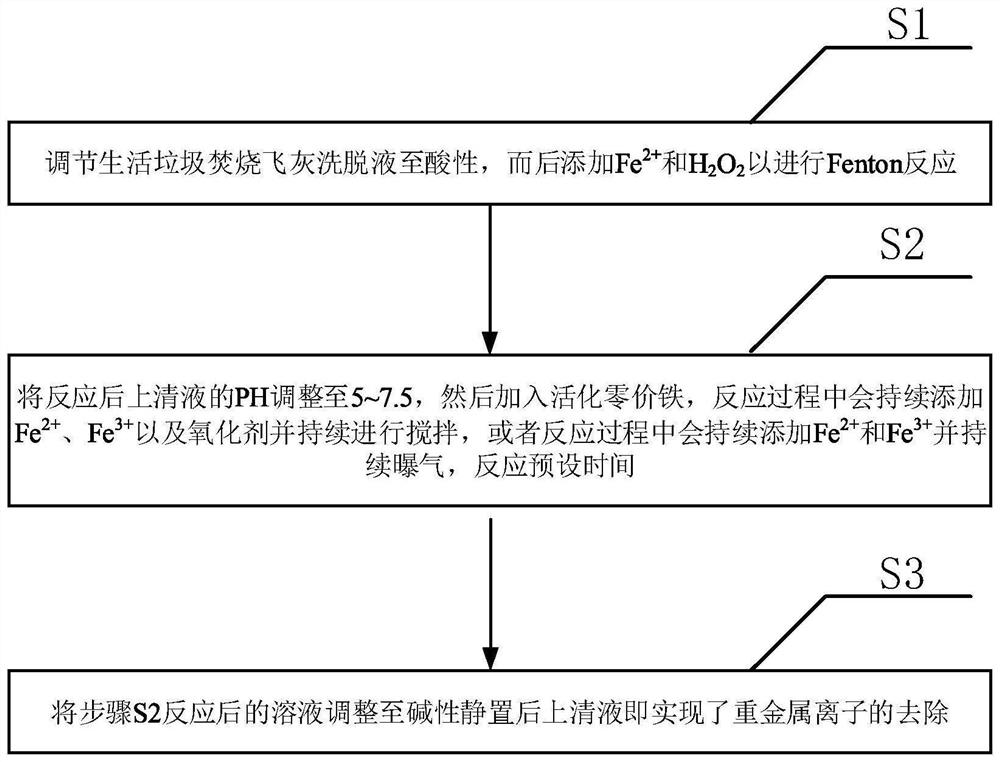

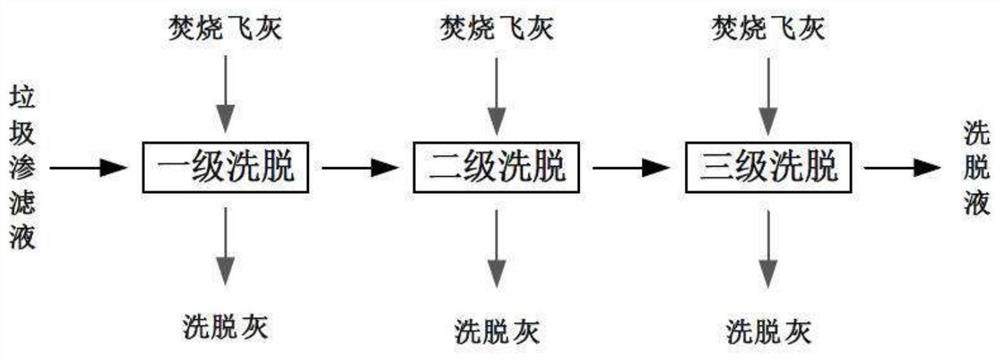

Method used

Image

Examples

Embodiment 1

[0053] In this embodiment, separate Fenton process, single activated zero-valent iron process, activated zero-valent iron+Fenton simultaneous treatment process, Fenton process after activated zero-valent iron treatment, and the method in this application respectively carry out metal ion removal. The results are shown in Table 1 below.

[0054] Separate Fenton process: Add 2ppm of Mn, Pb, Cu, As, Se, Hg ions to the eluent respectively, and use actual wastewater to simulate the eluent with high heavy metal concentration. Use 5M dilute hydrochloric acid solution to adjust pH=4, add 4500ppm FeSO 4 After mixing well, add 3300ppm H 2 o 2 , reacted at 25°C, 300rpm shaker for 1h, and measured the ion concentration and COD after filtration.

[0055] Activation of the zero-valent iron process alone: experiment with the eluent. Add 2ppm of Mn, Pb, Cu, As, Se, Hg ions to the eluent respectively, and use actual wastewater to simulate the eluent with high heavy metal concentration. U...

Embodiment 2

[0065] Using the method in this application, the influence of different reaction times on the removal effect of heavy metals was investigated, and the results are shown in Table 2 below.

[0066] Step S2 Reaction 2h: Add 2ppm of Mn, Pb, Cu, As, Se, Hg ions to the eluent respectively, and use actual wastewater to simulate the eluent with high heavy metal concentration. Use NaOH to adjust pH=7, add 30-60g / L excess activated zero-valent iron, 20ppm FeSO 4 and 10ppm FeCl 3 , the reaction took place in a constant temperature water bath at 25°C and a stirring speed of 300rpm, and the reaction time was 120 minutes. The concentration of each ion was measured after interval sampling and filtration.

[0067] Step S2 Reaction 6h: Add 2 ppm of Mn, Pb, Cu, As, Se, Hg ions to the eluent respectively, and use actual wastewater to simulate the eluent with high heavy metal concentration. Use NaOH to adjust pH=7, add 30-60g / L excess activated zero-valent iron, react in a constant temperature...

Embodiment 3

[0073] This example is used to verify that the method also has a good treatment effect when dealing with eluents with high heavy metal concentrations.

[0074] Add 2ppm of Mn, Pb, Cu, As, Se, Hg ions to the eluent respectively, and use actual wastewater to simulate the eluent with high heavy metal concentration. Use 5M dilute hydrochloric acid solution to adjust pH=4, add 4500ppm FeSO 4 After mixing well, add 3300ppm H 2 o 2 , reacted at 25°C, 250rpm shaker. Use NaOH to adjust pH=7, add 30-60g / L excess activated zero-valent iron, react in a constant temperature water bath at 25°C, and stir at a speed of 300rpm, add 20ppm FeSO every 2h during the reaction process 4 and 10ppm FeCl 3 , Reaction time 6h. Adjust pH=9 and let stand for 30 minutes before sampling. The concentration of each ion was measured after interval sampling and filtration. The results are shown in Table 3.

[0075]

[0076] table 3

[0077] It can be seen from Table 3 that the Fenton plus activated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com