High-moisture peeled walnut with low browning index and preparation method thereof

A high-moisture, high-index technology, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems affecting the sensory quality of walnut products, the inability to keep the taste fresh and crisp, and the high water content of walnut kernels. Achieve the effects of reducing the probability of browning, improving sensory quality, and reducing skin abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of the high-moisture peeling walnut with low browning index comprises the following steps:

[0046] S1. Soak the dried walnut kernels in water at a temperature of 35° C. for 7 minutes to soak the walnut kernels;

[0047] Rinse and soak the walnut kernels with a pressure of 50 Pa for 13 minutes, then rinse and soak the walnut kernels with a pressure of 80 Pa for 8 minutes to obtain peeled walnut kernels;

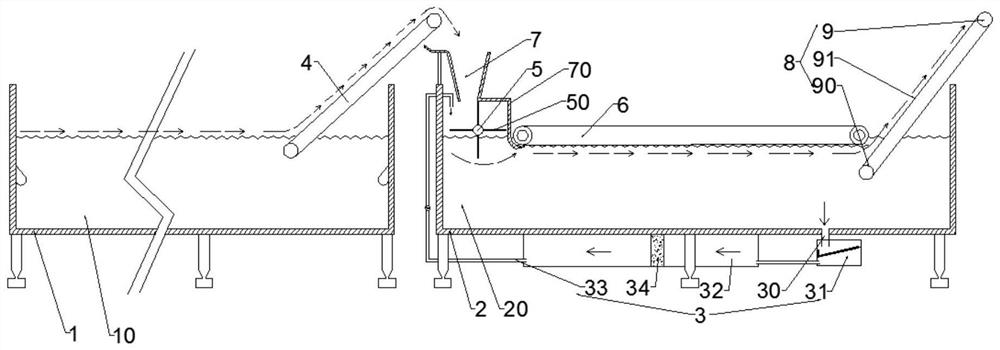

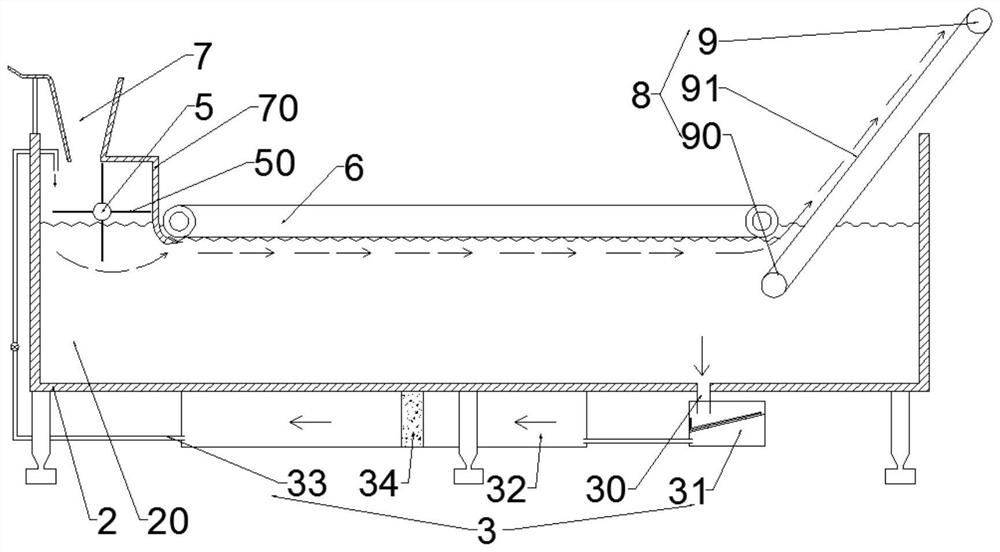

[0048]S2. Put the peeled walnut kernels in the bubbling water tank 10 of the bubbling machine 1, add water and an adsorbent material accounting for 2% of the water quality, and inject air for bubbling and cleaning for 1 min, wherein the adsorbent material is polysaccharide gel particles, In the specific operation process, put the adsorbent material into the metal ball with holes, and fix it on the wall of the bubbler 1 with a thread, etc., which is conducive to the separation of walnut kernels during continuous operation, and ensures that the dis...

Embodiment 2

[0056] The preparation method of the high-moisture peeling walnut with low browning index comprises the following steps:

[0057] S1. Soak the dried walnut kernels in water at a temperature of 30° C. for 5 minutes to soak the walnut kernels;

[0058] Rinse and soak the walnut kernels with a pressure of 60 Pa for 10 minutes, and then rinse and soak the walnut kernels for 5 minutes with a pressure of 100 Pa to obtain peeled walnut kernels;

[0059] S2. Put the peeled walnut kernels in the bubbling water tank 10 of the bubbling machine 1, add water and an adsorbent material accounting for 0.05% of the water quality, and feed air for bubbling and cleaning for 2 minutes, wherein the adsorbent material is activated carbon. The specific operation process Put the absorbent material into a nylon mesh bag, and fix it on the wall of the bubbler 1 with a string or the like;

[0060] Place the peeled walnut kernels after bubbling and cleaning in the ultrasonic water tank of the ultrasonic...

Embodiment 3

[0066] The preparation method of the high-moisture peeling walnut with low browning index comprises the following steps:

[0067] S1. Soak the dried walnuts in water at a temperature of 40°C for 10 minutes to soak the walnuts;

[0068] Rinse and soak the walnut kernels with a pressure of 40 Pa for 15 minutes, and then wash and soak the walnut kernels for 10 minutes with a pressure of 70 Pa to obtain peeled walnut kernels;

[0069] S2. Put the peeled walnut kernels in the bubbling water tank 10 of the bubbling machine 1, add water and an adsorbent material accounting for 3% of the water mass, and feed air into it for bubbling and cleaning for 1 min, wherein the adsorbent material is activated clay. The specific operation During the process, put the absorbent material into a nylon mesh bag, and fix it on the wall of the bubbler 1 with a string or the like;

[0070] Place the peeled walnut kernels after bubbling and cleaning in the ultrasonic water tank of the ultrasonic machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com