Precision control mechanism for milling aluminum alloy thin-wall part

A milling and precision control technology, used in metal processing mechanical parts, metal processing, metal processing equipment, etc., can solve the problems of insufficient rotation speed, slow efficiency, aluminum alloy damage, etc., to avoid recycling and avoid falling, rotating The effect of increased speed and avoidance of milling errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

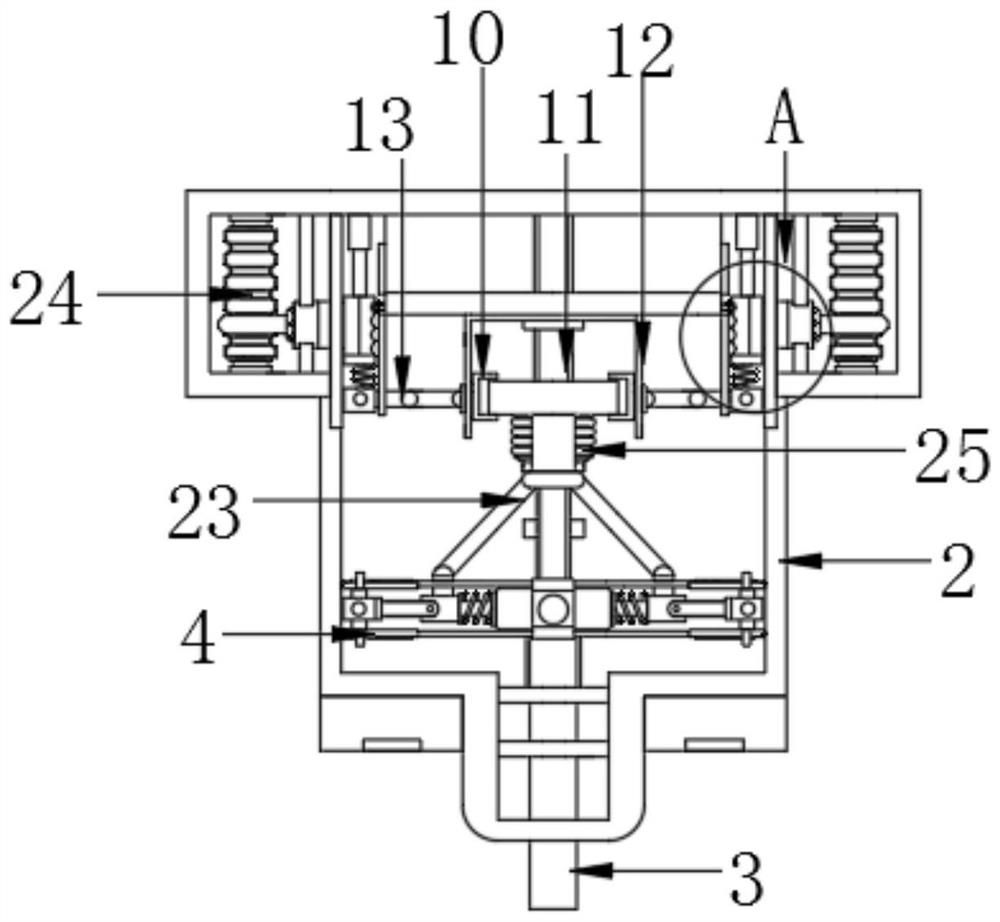

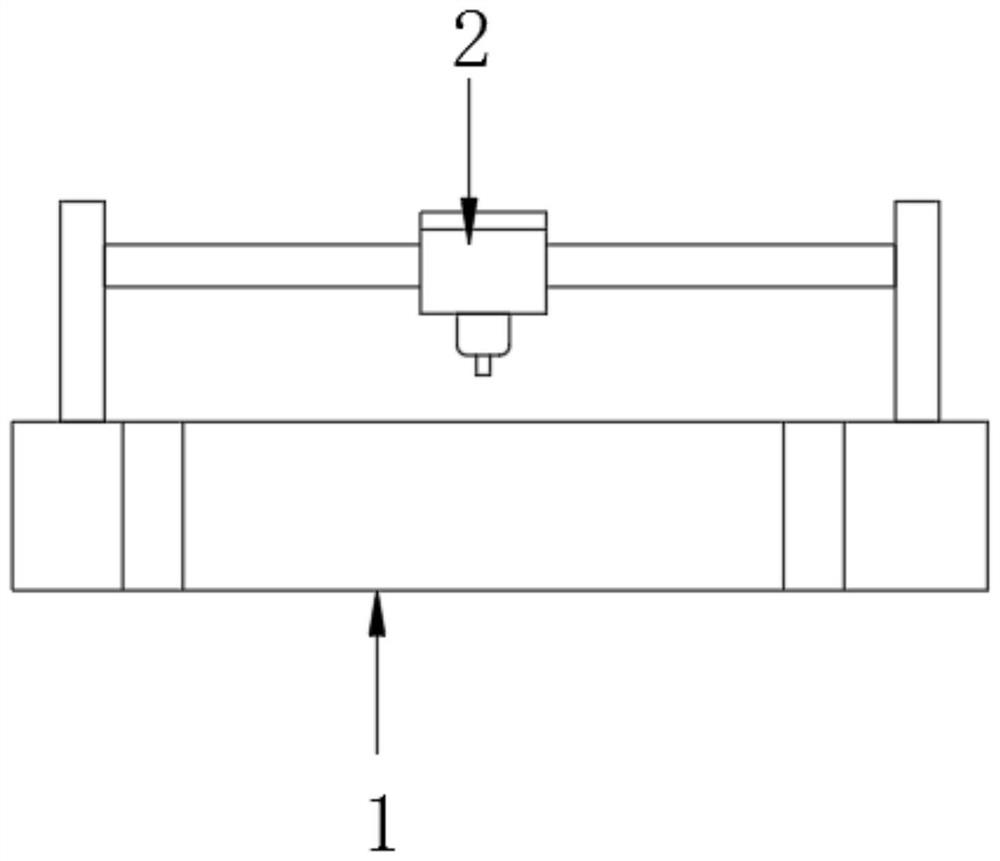

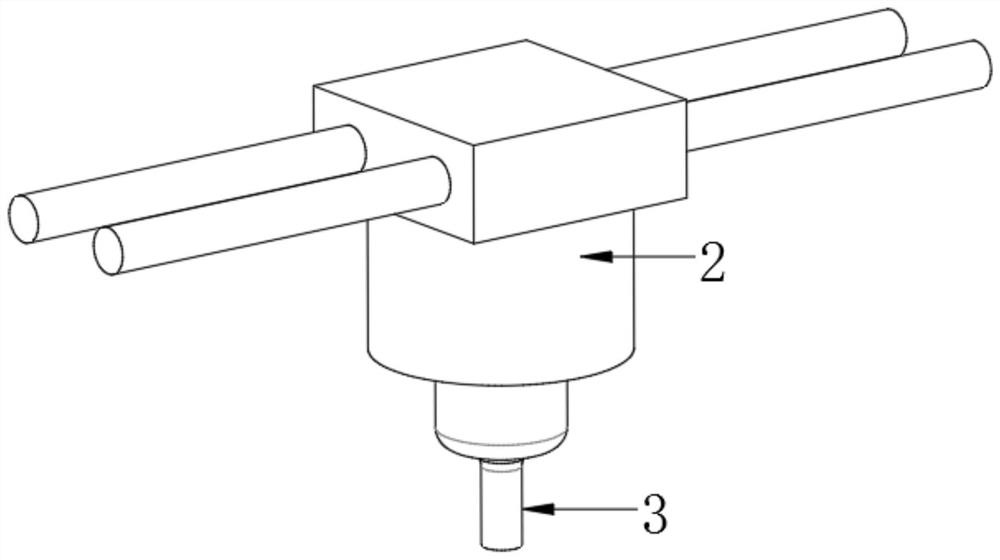

[0029] see figure 1 and 6 , a precision control mechanism for milling aluminum alloy thin-walled parts, comprising a base 1, the top of the base 1 is movably connected to a milling mechanism 2, the inner wall of the milling mechanism 2 is rotatably connected to a milling cutter 3, and the top of the milling cutter 3 is fixed Connected with a milling rotary mechanism 23, the outer wall of the milling rotary mechanism 23 is movably connected with a ring clip 10, the inner wall of the milling rotary mechanism 23 is fixedly connected with a telescopic rod 11, and the outer wall of the ring clip 10 is slidably connected with a vertical rail 12, the ring A lever 13 is hinged on the side of the sleeve clamp 10 away from the telescopic rod 11 , and an end of the lever 13 away from the sleeve clamp 10 is movably connected with a clamping mechanism 24 , and the top of the milling rotation mechanism 23 is movably connected with a recovery mechanism 25 .

[0030] Further, the clamping me...

Embodiment 2

[0033] see figure 1 and 7 , a precision control mechanism for milling aluminum alloy thin-walled parts, comprising a base 1, the top of the base 1 is movably connected to a milling mechanism 2, the inner wall of the milling mechanism 2 is rotatably connected to a milling cutter 3, and the top of the milling cutter 3 is fixed Connected with a milling rotary mechanism 23, the outer wall of the milling rotary mechanism 23 is movably connected with a ring clip 10, the inner wall of the milling rotary mechanism 23 is fixedly connected with a telescopic rod 11, and the outer wall of the ring clip 10 is slidably connected with a vertical rail 12, the ring A lever 13 is hinged on the side of the sleeve clamp 10 away from the telescopic rod 11 , and an end of the lever 13 away from the sleeve clamp 10 is movably connected with a clamping mechanism 24 , and the top of the milling rotation mechanism 23 is movably connected with a recovery mechanism 25 .

[0034] Further, the recovery me...

Embodiment 3

[0037] see Figure 1-7 , a precision control mechanism for milling aluminum alloy thin-walled parts, comprising a base 1, the top of the base 1 is movably connected to a milling mechanism 2, the inner wall of the milling mechanism 2 is rotatably connected to a milling cutter 3, and the top of the milling cutter 3 is connected to the The runner rail 4 is fixedly connected, the outer wall of the ring layer 8 is movably connected with the ring clip 10, and the outer wall of the milling cutter 3 is in contact with the aluminum alloy.

[0038]The top of milling cutter 3 is fixedly connected with milling rotary mechanism 23, and milling rotary mechanism 23 comprises runner rail 4, and the inner wall of runner rail 4 is fixedly connected with centrifugal spring 5, and one end of centrifugal spring 5 away from runner rail 4 is fixedly connected with sliding Block 6, the positive and negative sides of the slider 6 are slidingly connected with the runner rail 4, the outer wall of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com