Method for obtaining foot shape

A foot shape and double foot technology, applied in the field of foot shape acquisition, can solve the problems of inconvenient customer operation, cumbersome steps, and many use restriction factors, and achieve the effect of meeting the needs of customized shoes, accurate model data, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

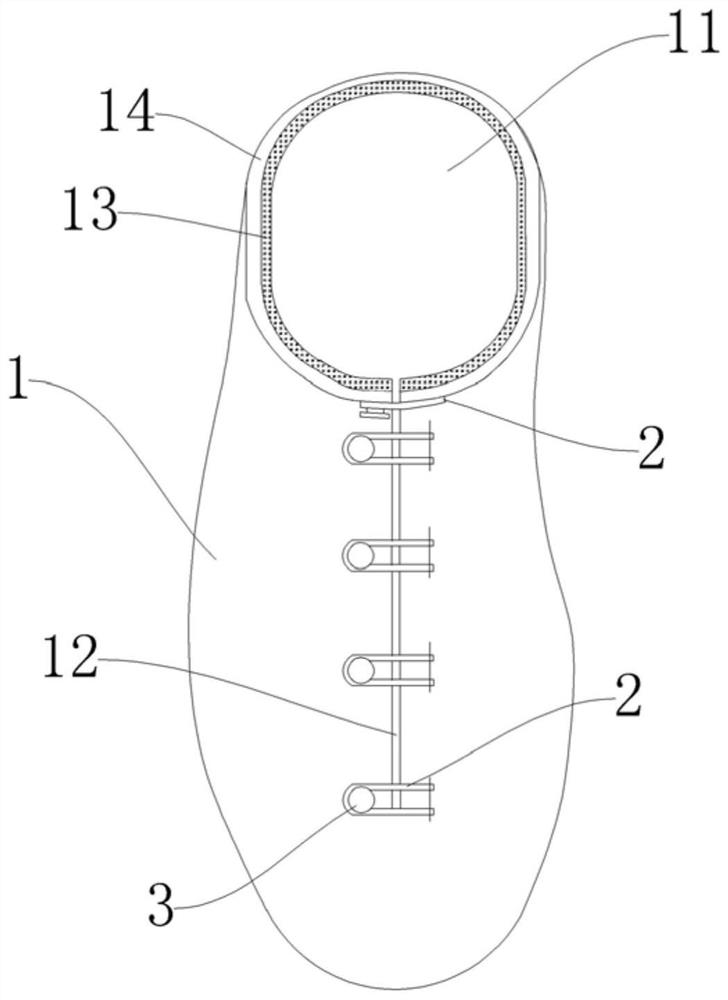

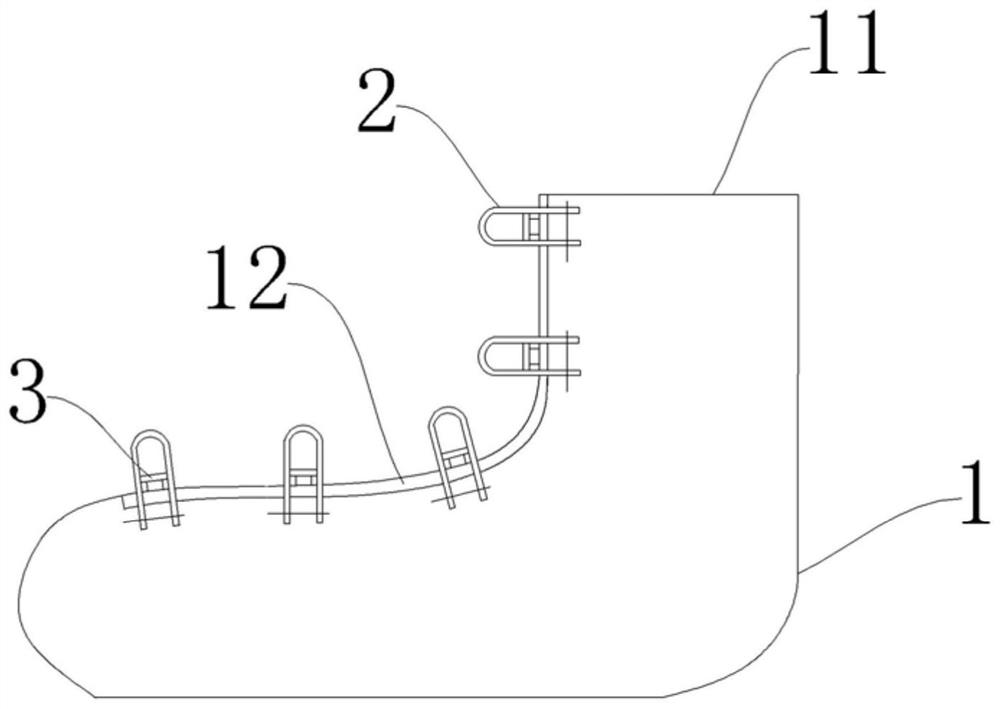

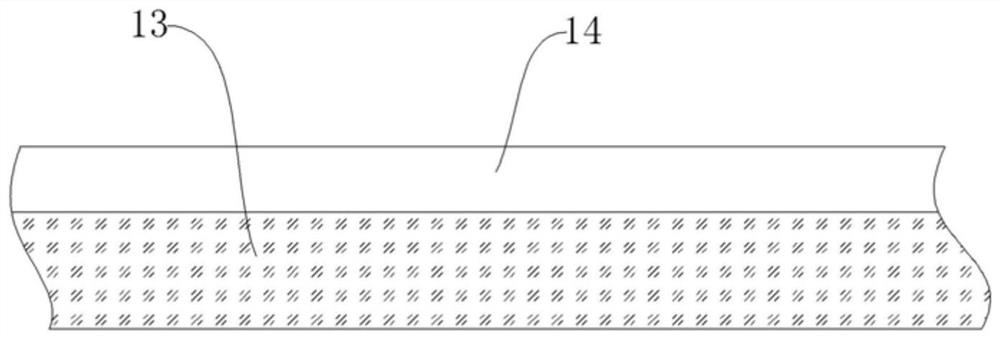

[0026] refer to figure 1 , figure 2 with image 3 , In this embodiment, the socks are provided with a sock body 1, a buckle 2 and a fixed buckle 3, the sock body 1 includes a knitted layer 13 and a water-cured polyurethane layer 14, and the water-cured polyurethane layer 14 wraps the knitted layer 13. One end of the sock body 1 is provided with a sock opening 11 and an opening 12. One end of the opening 12 is located at the sock opening 11, and the other end is located at the instep of the sock. The buckle 2 and the fixing buckle 3 are respectively located on both sides of the opening 12. The buckle 2 Corresponding to the position of the fixing buckle 3 , one end of the buckle 2 is fixedly connected to the knitted layer 13 of the sock body 1 on one side of the opening 12 , and the other end is detachably connected to the fixing buckle 3 .

[0027] When obtaining a 3D foot shape, by setting one end of the buckle 2 on the corresponding fixing buckle 3, the opening 12 is kept ...

Embodiment 2

[0031] refer to figure 1 , figure 2 with image 3 , In this embodiment, the socks are provided with a sock body 1, a buckle 2 and a fixed buckle 3, the sock body 1 includes a knitted layer 13 and a water-cured polyurethane layer 14, and the water-cured polyurethane layer 14 wraps the knitted layer 13. One end of the sock body 1 is provided with a sock opening 11 and an opening 12. One end of the opening 12 is located at the sock opening 11, and the other end is located at the instep of the sock. The buckle 2 and the fixing buckle 3 are respectively located on both sides of the opening 12. The buckle 2 Corresponding to the position of the fixing buckle 3 , one end of the buckle 2 is fixedly connected to the knitted layer 13 of the sock body 1 on one side of the opening 12 , and the other end is detachably connected to the fixing buckle 3 .

[0032] When obtaining the 3D foot shape, by setting one end of the buckle 2 on the corresponding fixing buckle 3, the opening 12 is kep...

Embodiment 3

[0036] refer to figure 1 , figure 2 with image 3 , In this embodiment, the socks are provided with a sock body 1, a buckle 2 and a fixed buckle 3, the sock body 1 includes a knitted layer 13 and a water-cured polyurethane layer 14, and the water-cured polyurethane layer 14 wraps the knitted layer 13. One end of the sock body 1 is provided with a sock opening 11 and an opening 12. One end of the opening 12 is located at the sock opening 11, and the other end is located at the instep of the sock. The buckle 2 and the fixing buckle 3 are respectively located on both sides of the opening 12. The buckle 2 Corresponding to the position of the fixing buckle 3 , one end of the buckle 2 is fixedly connected to the knitted layer 13 of the sock body 1 on one side of the opening 12 , and the other end is detachably connected to the fixing buckle 3 .

[0037] When obtaining a 3D foot shape, by setting one end of the buckle 2 on the corresponding fixing buckle 3, the opening 12 is kept ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com