Lithium ion battery positive pole piece and preparation method thereof

A technology for lithium-ion batteries and positive pole pieces, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of complex pre-synthesis process of positive electrode materials, is not conducive to industrial application, and increases additional costs, so as to achieve easy industrial production , high energy density, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The mass percent of the lithium-rich manganese-based material in the positive electrode active material is 50%:

[0046] 1) Check the airtightness of the batching pot to ensure that there is no abnormality in the airtightness, and then add 800g of carbon nanotube slurry (Jiangsu Tiannai Technology Co., Ltd., LB100-50) and 56g of polyvinylidene fluoride glue (Ruyuan Dongyangguang Fluoride Co., Ltd. Resin Co., Ltd., HEVER601), then add 500g N-methylpyrrolidone, and stir for 60min;

[0047] 2) Open the batching pot, add 20g conductive carbon black, 20g graphite and 2400g single crystal ternary material LiNi 0.55 co 0.15 mn 0.3 o 2 (Nickel 55 ternary, median particle size D50 is 3-8μm, specific surface area is 0.3-0.8m 2 / g), stirring for 60min;

[0048] 3) Open the batching pot and add 2400g lithium-rich manganese-based material Li 1.15 Ni 0.35 mn 0.5 o 2 (median particle size D50 is 5-10μm, specific surface area is 0.5-1.0m 2 / g), stirred for 60min to obtain the...

Embodiment 2

[0061] The content of lithium-rich manganese-based materials in the positive electrode active material is 20%:

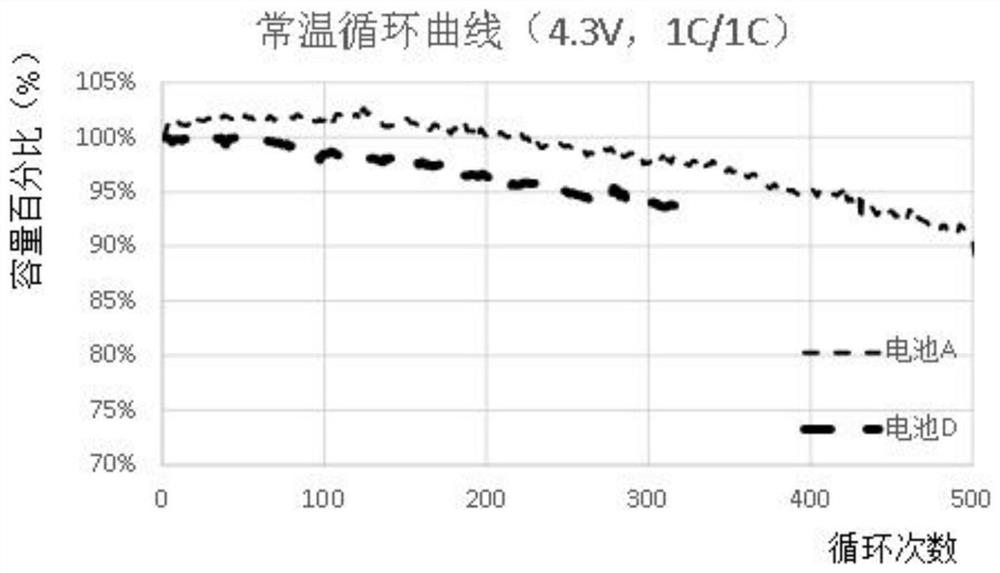

[0062] On the basis of Example 1, the addition amount of the single crystal ternary material in the second step and the addition amount of the lithium-rich manganese-based material in the third step were adjusted to 3840 g and 960 g. Similarly, the slurry was made into an electrode, and a battery D was assembled with a conventional negative electrode material with graphite as the active material, and the electrical performance was tested.

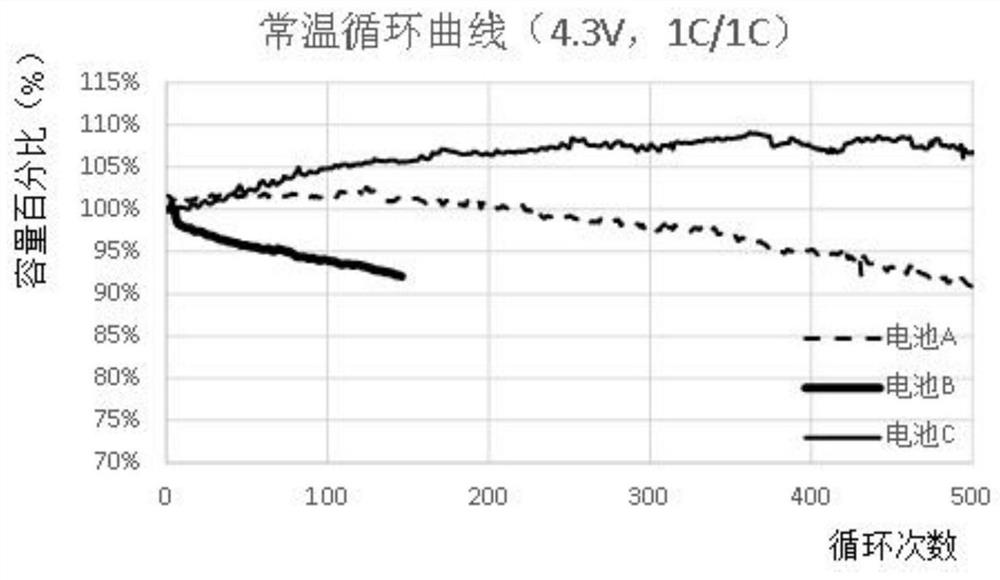

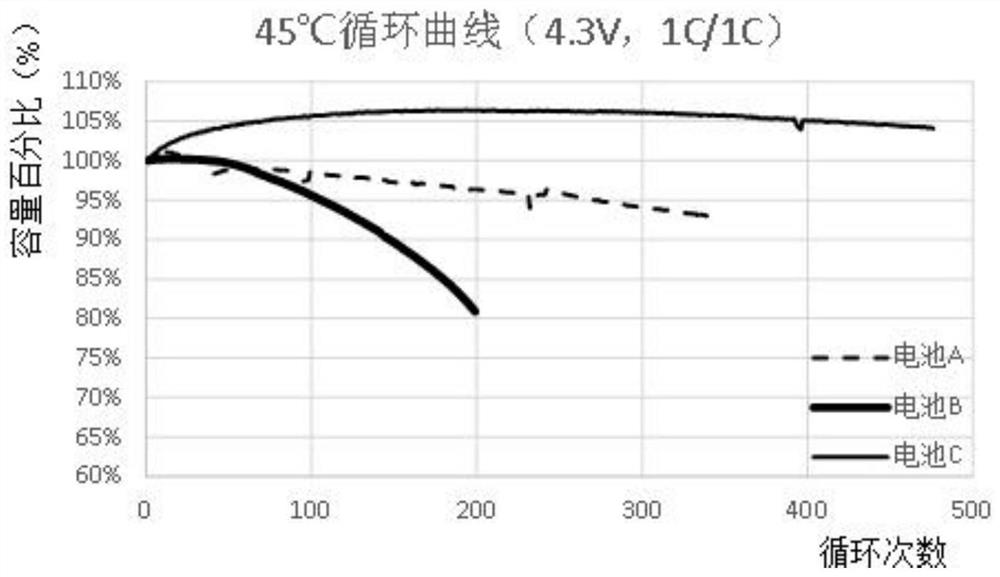

[0063] Such as figure 1 and figure 2 As shown, the 1C / 1C cycle performance of battery A at room temperature and high temperature is better than that of batteries B and C. It can be seen that the battery 1C / 1C cycle performance of the positive electrode active material formed by combining single crystal ternary materials and lithium-rich manganese-based materials is better than that of batteries alone A battery using single cry...

Embodiment 3

[0065] 1) Check the airtightness of the batching pot to ensure that there is no abnormality in the airtightness, then add 800g of carbon nanotube slurry and 69g of polyvinylidene fluoride glue, then add 500g of acetone, and stir for 90min;

[0066] 2) Open the batching pot, add 16g conductive carbon black, 16g graphite and 2400g nickel 55 ternary, stir for 90min;

[0067] 3) Open the batching pot and add 2400g lithium-rich manganese-based material Li 1.15 Ni 0.35 mn 0.5 o 2 , stirred for 60min to obtain the slurry stock solution;

[0068] 4) Finally, adjust the viscosity of the slurry stock solution to about 14000mpa.s by adding N-methylpyrrolidone, and continue stirring for 180min to obtain the positive electrode slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com