Anti-radiation packaging structure and method

A packaging structure, anti-radiation technology, applied in the direction of electrical components, electrical solid devices, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

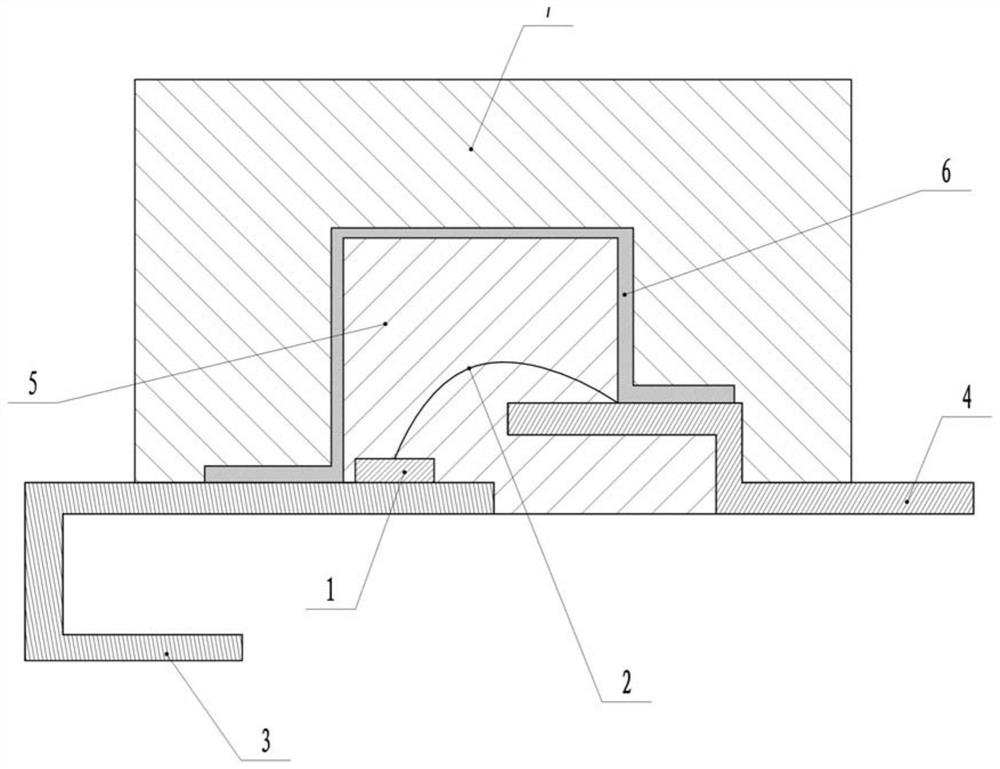

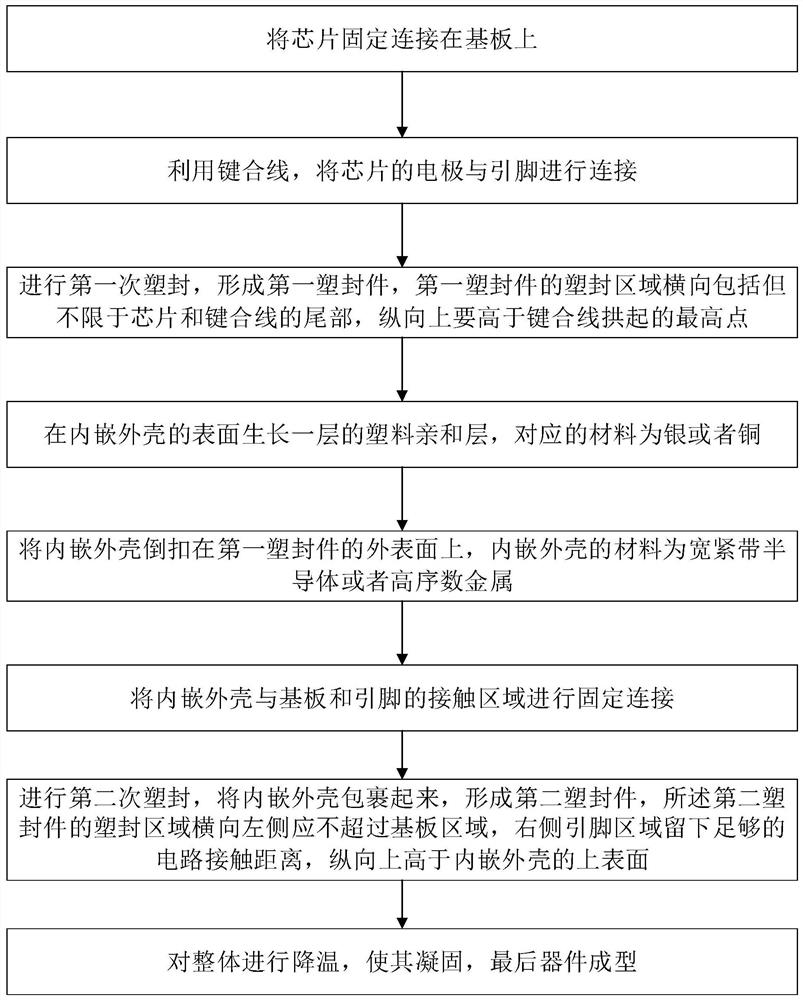

[0051] Embodiment one is basically as attached figure 1 Shown: a radiation-resistant packaging structure, including an embedded shell 6, and a first plastic package 5 and a second plastic package 7 for plastic packaging the device to be plastic packaged.

[0052] The device to be plastic-encapsulated includes a substrate 3 , pins 4 , a chip 1 and a bonding wire 2 , the chip 1 is fixedly connected to the substrate 3 through solder paste, and the chip 1 and the pins 4 are interconnected through the bonding wire 2 .

[0053] In this embodiment, when the first plastic package 5 is plastic-sealed, the chip 1 and the bonding wire 2 are arranged inside the first plastic package 5, so that the plastic packaging requirements of this time are completed, and it is also for the purpose of achieving Radiation resistance requirements of chip 1 and bonding wire 2. The embedded shell 6 is turned upside down on the outer surface of the first plastic package 5 to meet the radiation resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com